Riveting device for automobile heat insulation part mold

A technology of heat insulator and riveter, applied in the direction of perforation tools, manufacturing tools, forming tools, etc., can solve the problems of position deviation, damage to the company's interests, loss of company order customers, etc., so as to reduce the cost of mold manufacturing and shorten the mold The effect of manufacturing cycle and saving debugging cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

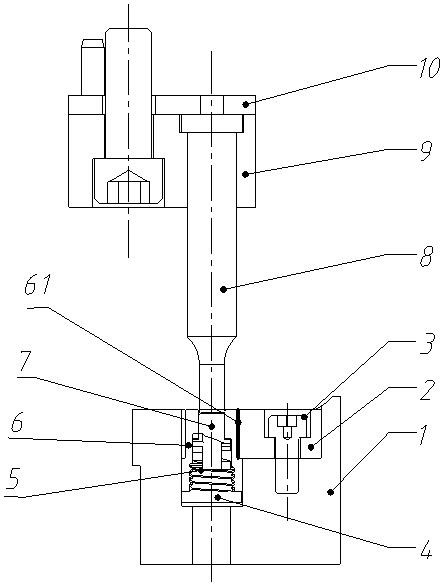

[0018] see figure 1 with figure 2 , a riveter for automotive heat insulation molds, comprising an upper mold part and a lower mold part connected to each other,

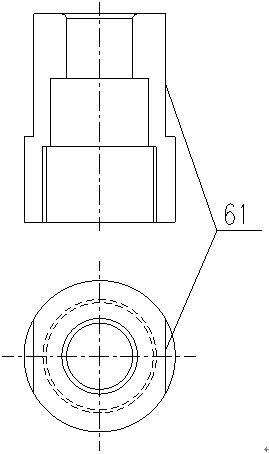

[0019] The lower mold part includes an insert 1, a pressing plate 2, a screw 3, a screw plug 4, a spring 5, a die 6 and an ejector pin 7; the insert 1 has a hole, and the screw plug 4, the spring 5, the concave The mold 6 and the ejector pin 7 are sequentially arranged in the hole from bottom to top, and the insert 1 is also provided with a mounting groove for installing the pressing plate 2 and a mounting screw hole for installing the screw 3, that is, the pressing plate 2 is installed. In the installation groove of the insert 1, the concave mold 6 is also provided with an anti-rotation surface 61, and the pressure plate 2 cooperates with the anti-rotation surface 61; the pressure plate 2 cooperates with the anti-rotation surface 61 of the concave mold 6 In order to achieve the problem of anti-rotation of the die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com