A high -temperature overall preheating auxiliary additive manufacturing device and method

A technology of additive manufacturing and high temperature, which is applied in the field of high-temperature overall preheating auxiliary additive manufacturing devices, can solve the problems of discontinuous preheating, low preheating temperature, small preheating area, etc., to reduce forming thermal stress, reduce Overall temperature gradient, effect of suppressing cracking tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

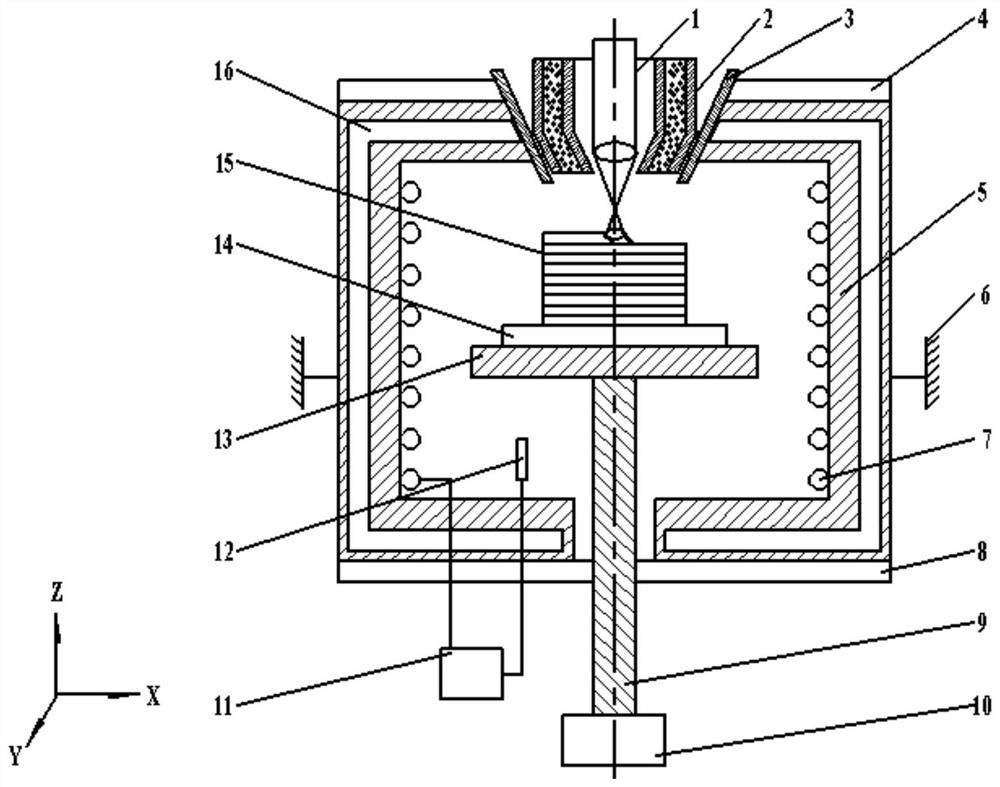

[0040] Direct laser deposition of Al assisted by high temperature bulk preheating 2 o 3 / Al 2 TiO 5 Composite ceramic materials as an example, such as figure 1 As shown, the high-temperature overall preheating assisted additive manufacturing device adopts the equipment of the invention, which specifically includes the following steps:

[0041] Fix the high-temperature chamber 5 on the load-bearing frame 6, install the heat-resistant protective cover of the additive deposition head on the additive deposition head 2, and ensure that the temperature of the additive deposition head 2 does not exceed 50°C during the forming process. The additive deposition head 2 enters the cavity through the upper opening of the high-temperature cavity 5, the substrate support rod 9 enters the cavity through the lower opening of the high-temperature cavity 5, and the upper part of the cavity 4 and the lower part of the cavity are respectively covered with a heat-insulating protective cover 4. ...

Embodiment 2

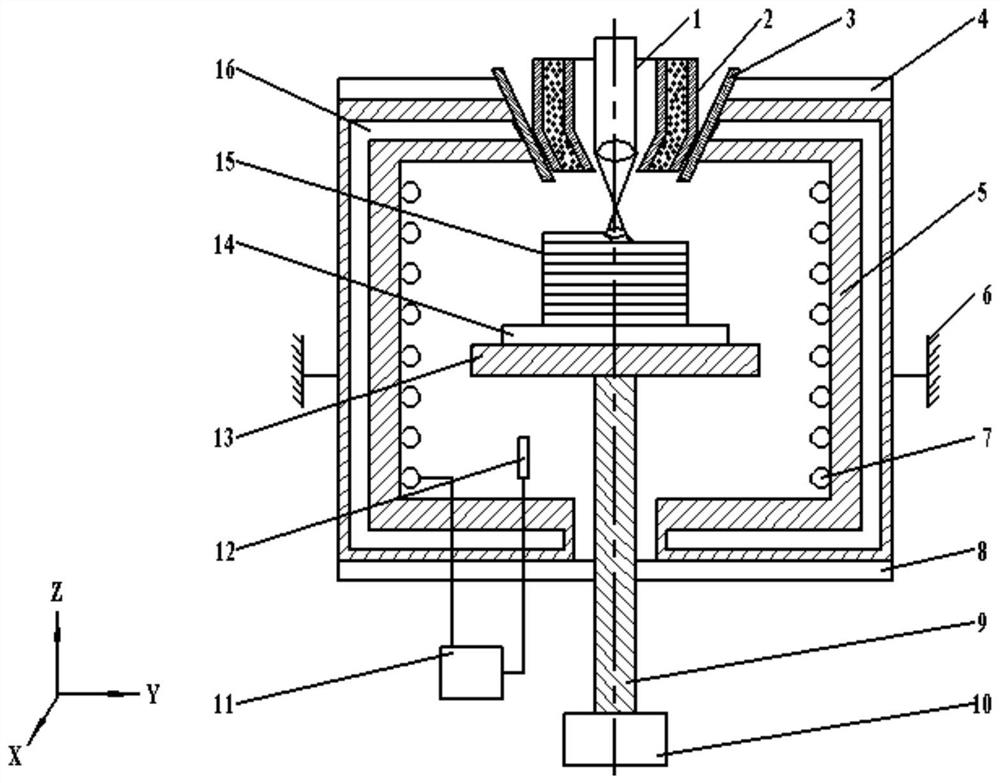

[0051] Direct laser deposition of Al assisted by high temperature bulk preheating 2 o 3 / Al 2 TiO 5 Composite ceramic materials as an example, such as figure 2 As shown, the high-temperature overall preheating assisted additive manufacturing device adopts the equipment of the invention, which specifically includes the following steps:

[0052] Fix the high-temperature chamber 5 on the load-bearing frame 6, install the heat-resistant protective cover of the additive deposition head on the additive deposition head 2, and ensure that the temperature of the additive deposition head 2 does not exceed 50°C during the forming process. The additive deposition head 2 enters the cavity through the upper opening of the high-temperature cavity 5, the substrate support rod 9 enters the cavity through the lower opening of the high-temperature cavity 5, and the upper part of the cavity 4 and the lower part of the cavity are respectively covered with a heat-insulating protective cover 4. ...

Embodiment 3

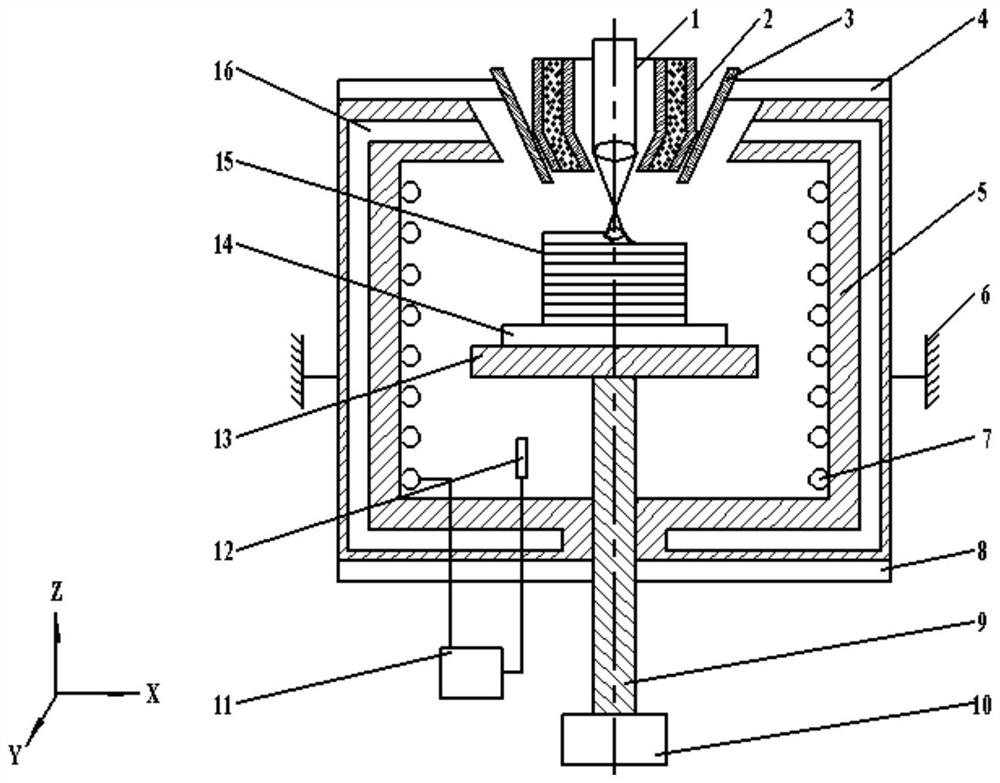

[0062] Direct laser deposition of Al assisted by high temperature bulk preheating 2 o 3 / Al 2 TiO 5 Composite ceramic materials as an example, such as image 3 As shown, the high-temperature overall preheating assisted additive manufacturing device adopts the equipment of the invention, which specifically includes the following steps:

[0063] Fix the high-temperature chamber 5 on the load-bearing frame 6, install the heat-resistant protective cover of the additive deposition head on the additive deposition head 2, and ensure that the temperature of the additive deposition head 2 does not exceed 50°C during the forming process. The additive deposition head 2 enters the cavity through the upper opening of the high-temperature cavity 5, the substrate support rod 9 enters the cavity through the lower opening of the high-temperature cavity 5, and the upper part of the cavity 4 and the lower part of the cavity are respectively covered with a heat-insulating protective cover 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com