Foaming equipment for irradiation crosslinking polyolefin production

A technology of cross-linked polyolefin and foaming equipment, which is applied in the field of irradiation cross-linked polyolefin production equipment, can solve the problems of smoke generation and difficult discharge of smoke, and achieve the effect of easy cleaning and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

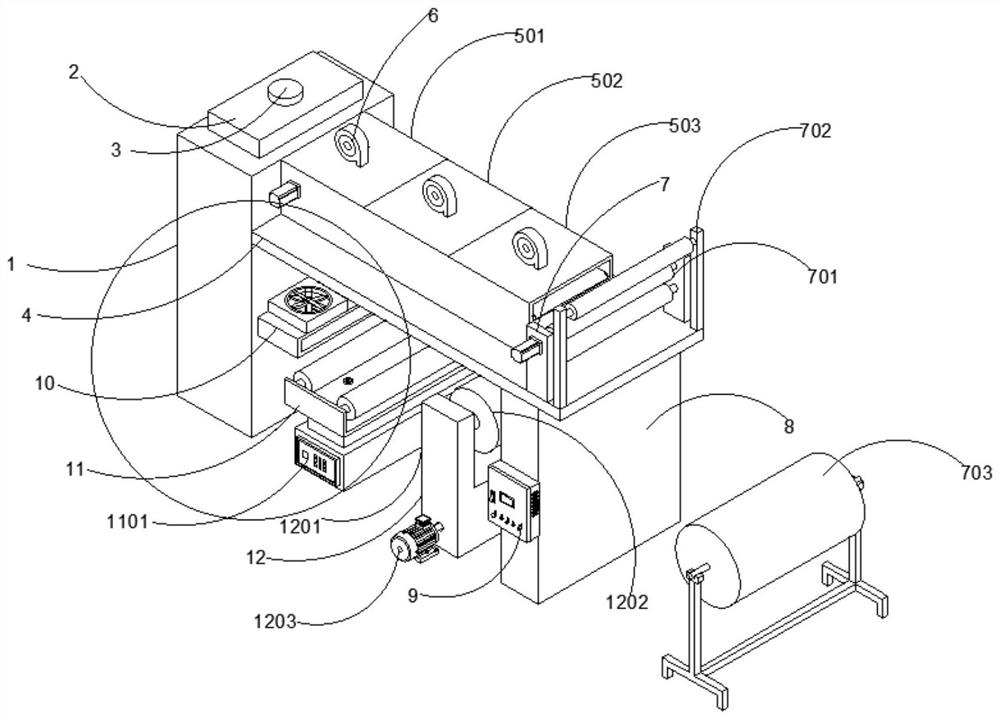

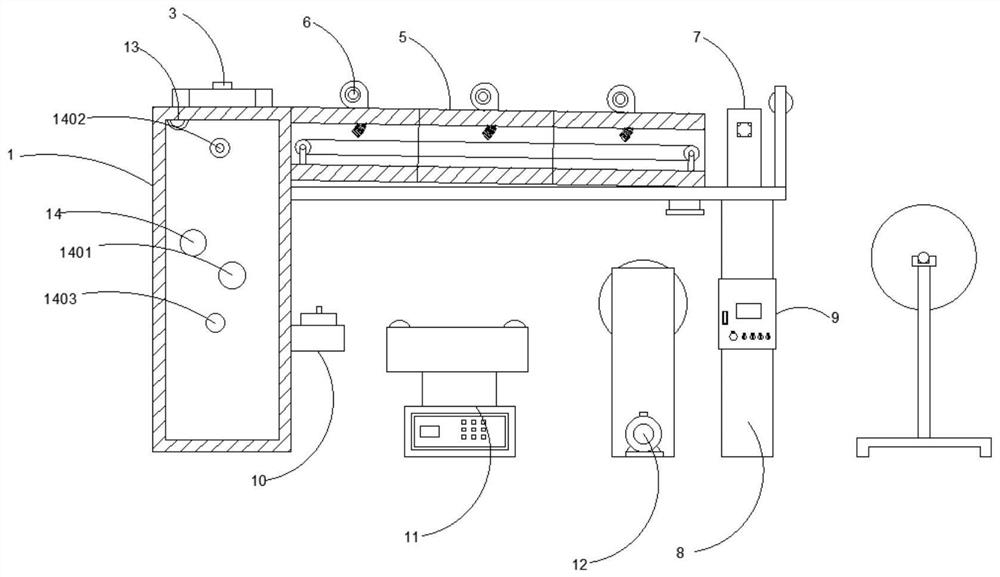

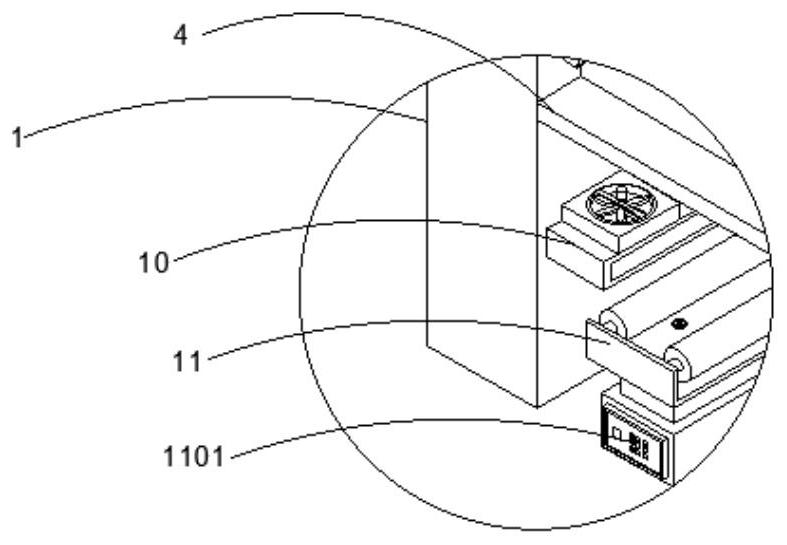

[0026] Such as Figure 1 to Figure 3 As shown, the present invention provides a foaming equipment for irradiation cross-linked polyolefin production, including a vertical heating foaming furnace 1 and an inclined preheating foaming furnace 5, and the top of the vertical heating foaming furnace 1 is set There is a tail gas treatment chamber 2, the top of the tail gas treatment chamber 2 is provided with a smoke outlet 3, the top of the vertical heating and foaming furnace 1 is fixedly connected with a fixed plate 4, and the top of the fixed plate 4 is fixedly connected with an inclined preheating A foaming furnace 5, one side of the top of the vertical heating foaming furnace 1 is fixedly connected with an inclined preheating foaming furnace 5, and the top of the inclined preheating foaming furnace 5 is fixedly connected with three blowers 6, and the fixed The top end of the plate 4 away from the vertical heating and foaming furnace is fixedly connected with a feeding mechanism...

Embodiment 2

[0035] Such as Figure 1 to Figure 3 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that a deviation correcting machine is provided to guide the direction of the material after foaming and cooling, and if the placement direction is incorrect, the material will be damaged;

[0036] By setting the winding mechanism, the material after foaming can be automatically wound, which greatly saves manpower.

[0037]By providing blower, tail gas treatment chamber and smoke outlet, the polluted waste gas produced by heating the foaming material will not be discharged from the inlet and outlet along the furnace chamber of the preheating foaming furnace, but will be discharged from the furnace ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com