Agricultural sugarcane smashing and juicing equipment

A sugarcane and juicing technology, applied in the field of agricultural sugarcane crushing and juicing equipment, can solve the problems of easy pollution, not easy to be squeezed dry, poor juicing effect, etc., and achieve the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

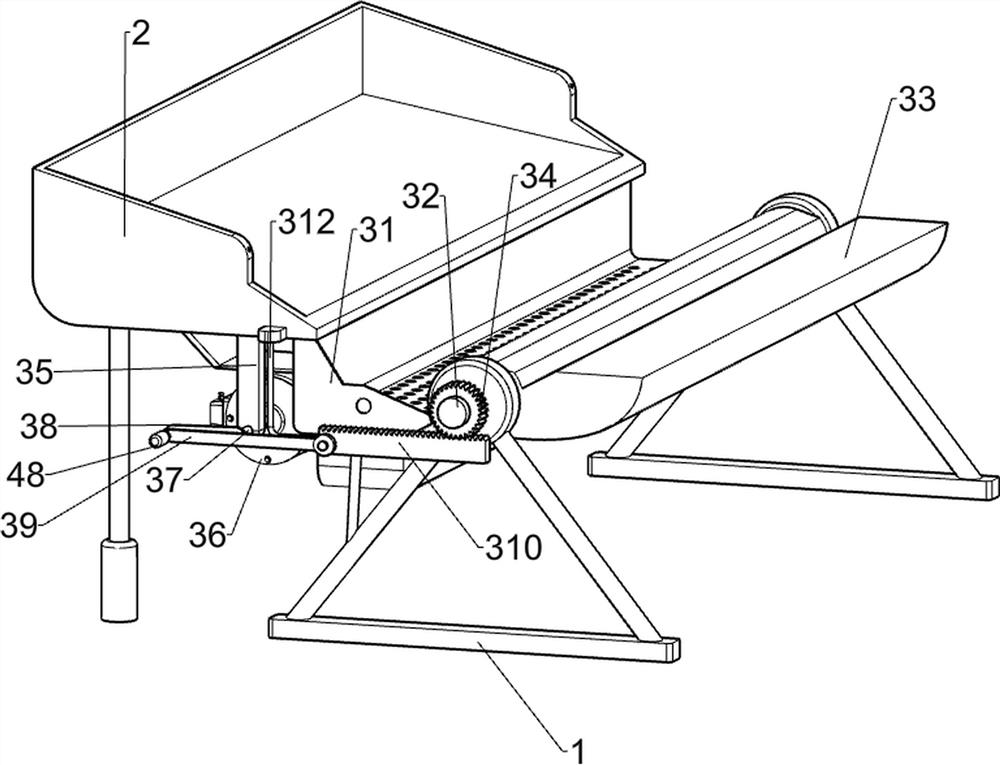

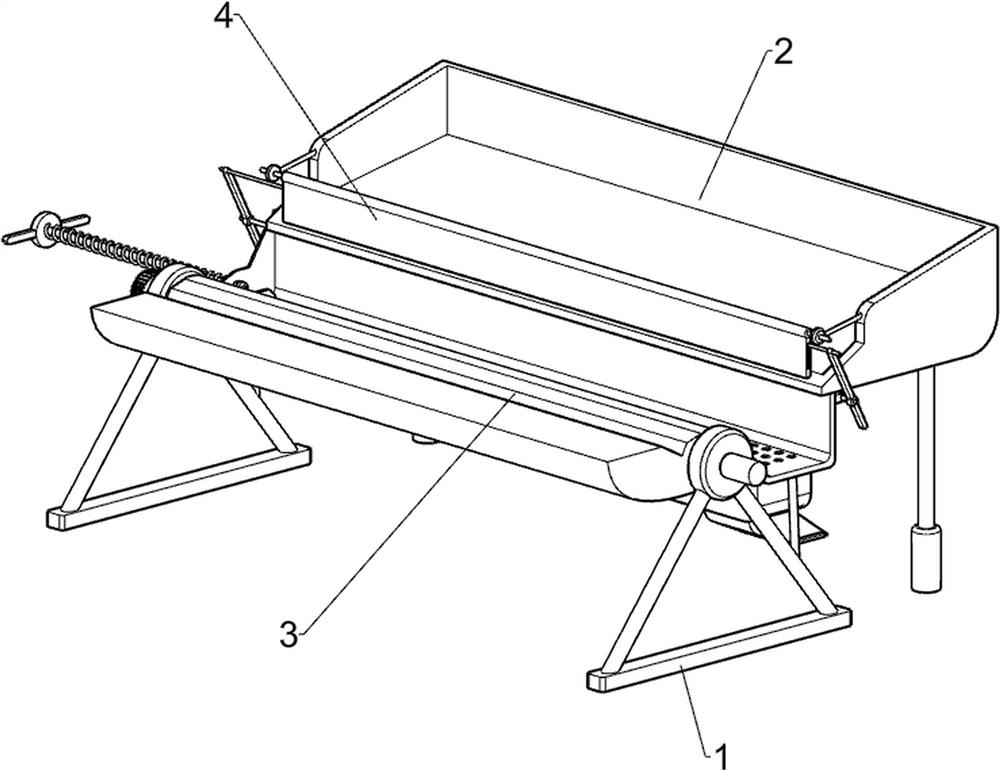

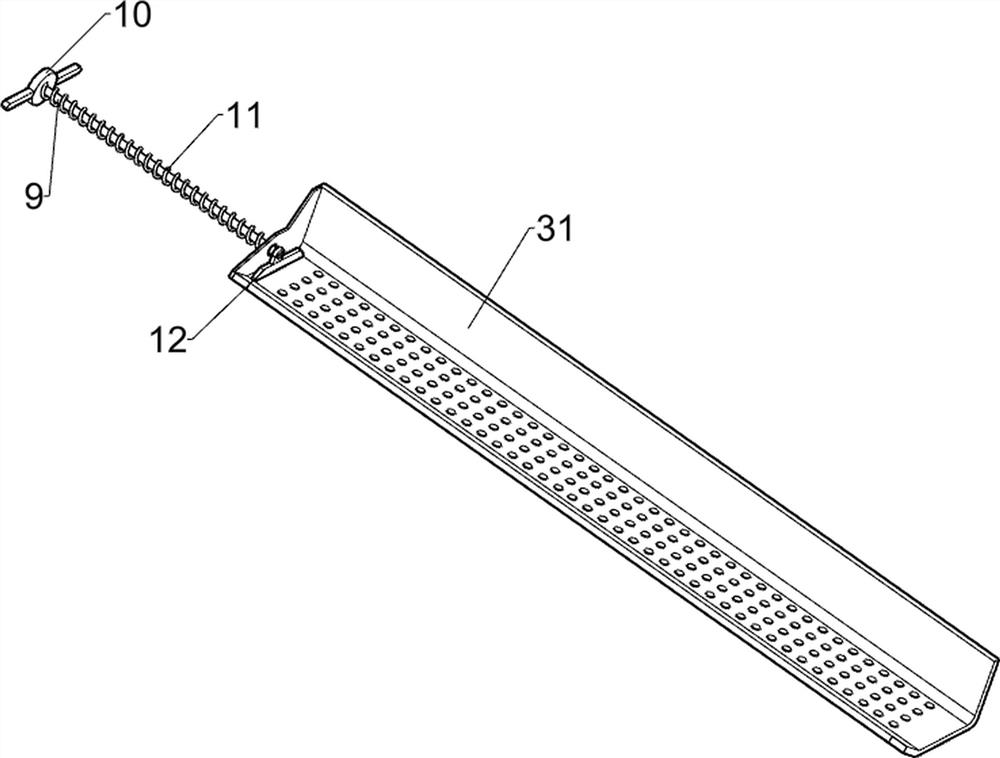

[0022] An agricultural sugarcane crushing and juicing equipment, such as figure 1 , figure 2 and image 3 As shown, it includes a support frame 1, a placement frame 2, an extrusion device 3 and a blanking device 4, an extrusion device 3 is arranged between the support frame 1 and the placement frame 2, the number of support frames 1 is two, and the support frame 1 Located on the left side of the placement frame 2, the placement frame 2 is provided with a feeding device 4.

[0023] When people need to use this device, first sugar cane is placed on the placement frame 2, and the collection tool is placed under the extrusion device 3, because the bottom of the placement frame 2 is set as an inclined plane, so the sugar cane will slide to the left and the unloading device 4 contact, and then the extruding device 3 can be started, so that the extruding device 3 drives the 4 parts of the blanking device to rotate, and then no longer blocks the sugarcane in the placing frame 2, so...

Embodiment 2

[0029] On the basis of Example 1, such as Figure 4 and Figure 5 As shown, it also includes a collection frame 5, a discharge port 6, a baffle plate 7 and a handle 8, the bottom of the filter plate 31 is provided with a collection frame 5, the bottom of the front end of the collection frame 5 is provided with a discharge port 6, and the bottom of the discharge port 6 The sliding type is provided with a baffle plate 7, and the rear side of the baffle plate 7 is provided with a handle 8.

[0030]When the sugarcane is extruded by the extrusion block 33 to extract the juice, the squeezed juice will flow into the collection frame 5 through the through hole. Since the inner bottom of the collection frame 5 is a slope, the sugarcane juice will flow from the collection frame 5 to the outlet. In the feed port 6, when the juice in the collection frame 5 accumulates to a certain extent, people can turn off the servo motor 36 and align the collection tool with the discharge port 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com