Counterweight side-falling elevator structure

An elevator and redirection technology, which is used in elevators in buildings, lifting equipment in mines, transportation and packaging, etc., can solve the problem of increasing the difficulty of positioning components such as load-bearing beam traction machines, the large inclination of the traction machine, and the increase in Difficulty in installation of related components in elevator machine room

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

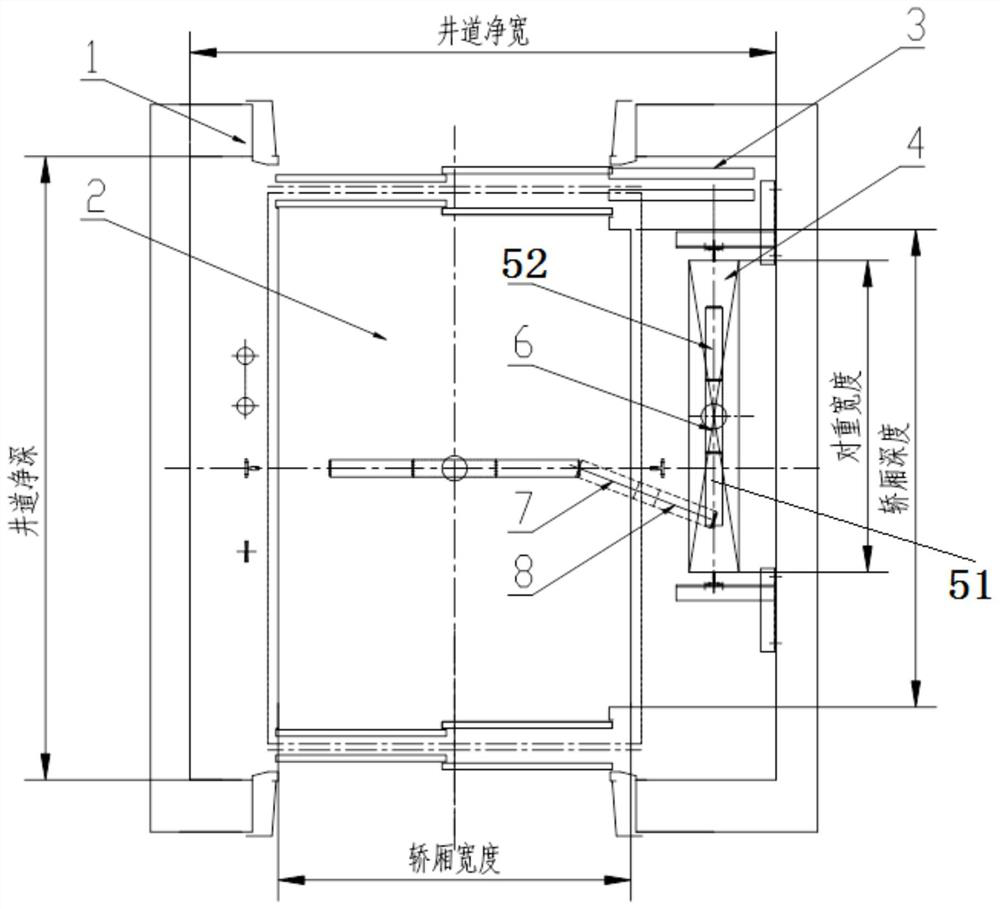

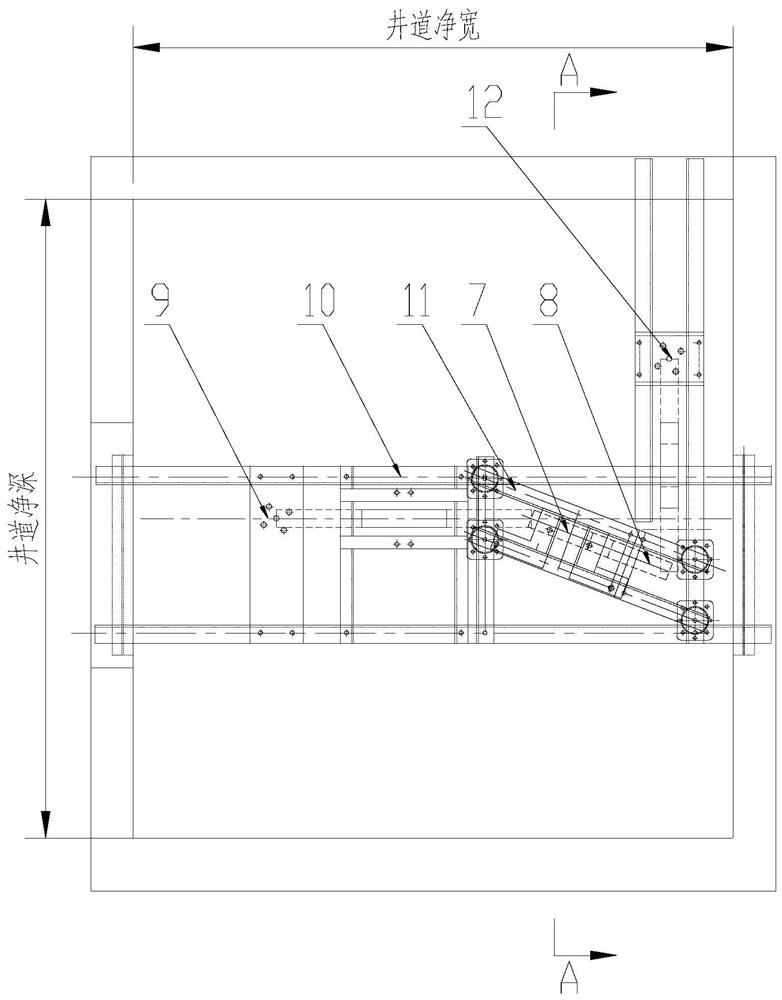

[0037] Such as Figure 4 , Figure 5 and Figure 6 As shown, the counterweight sideslip elevator structure includes a traction machine wheel 7, a machine room guide wheel 8, a traction wire rope 14, a counterweight 4, a first pair of returning sheaves 51, a second pair of returning sheaves 52, a first Counterweight guide wheel 61 and the second counterweight guide wheel 62;

[0038] The traction base 11 is fixed on the load-bearing beam 10 in the hoistway 1;

[0039] The traction wheel 7, the engine room guide wheel 8, the first counterweight guide wheel 61 and the second counterweight guide wheel 62 are fixed in the hoistway;

[0040] The first pair of heavy guide wheels 61 and the second pair of heavy guide wheels 62 are arranged at intervals one after the other;

[0041] The axes of the first pair of heavy guide wheels 61 and the second pair of heavy guide wheels 62 are parallel;

[0042] The machine room guide wheel 8 is located between the first pair of heavy guide w...

Embodiment 2

[0050] Based on the counterweight side-fall elevator structure of Embodiment 1, the traction machine wheel 7 is located between the first counterweight guide wheel 61 and the second counterweight guide wheel 62 in the front and rear direction (well way, car depth direction), and the traction The axis of machine wheel 7 is parallel to the axis of machine room guide wheel 8.

[0051] Preferably, the position of the traction wheel 7 is higher than that of the machine room guide wheel 8 .

[0052] Preferably, the traction machine wheel 7 is located directly above the machine room guide wheel 8 .

[0053] Preferably, the traction sheave 7 is arranged on the side near the car of the machine room guide wheel 8 .

[0054] In the counterweight side-fall elevator structure of Embodiment 2, the traction machine wheel 7 and the machine room guide wheel 8 can be placed horizontally or vertically.

Embodiment 3

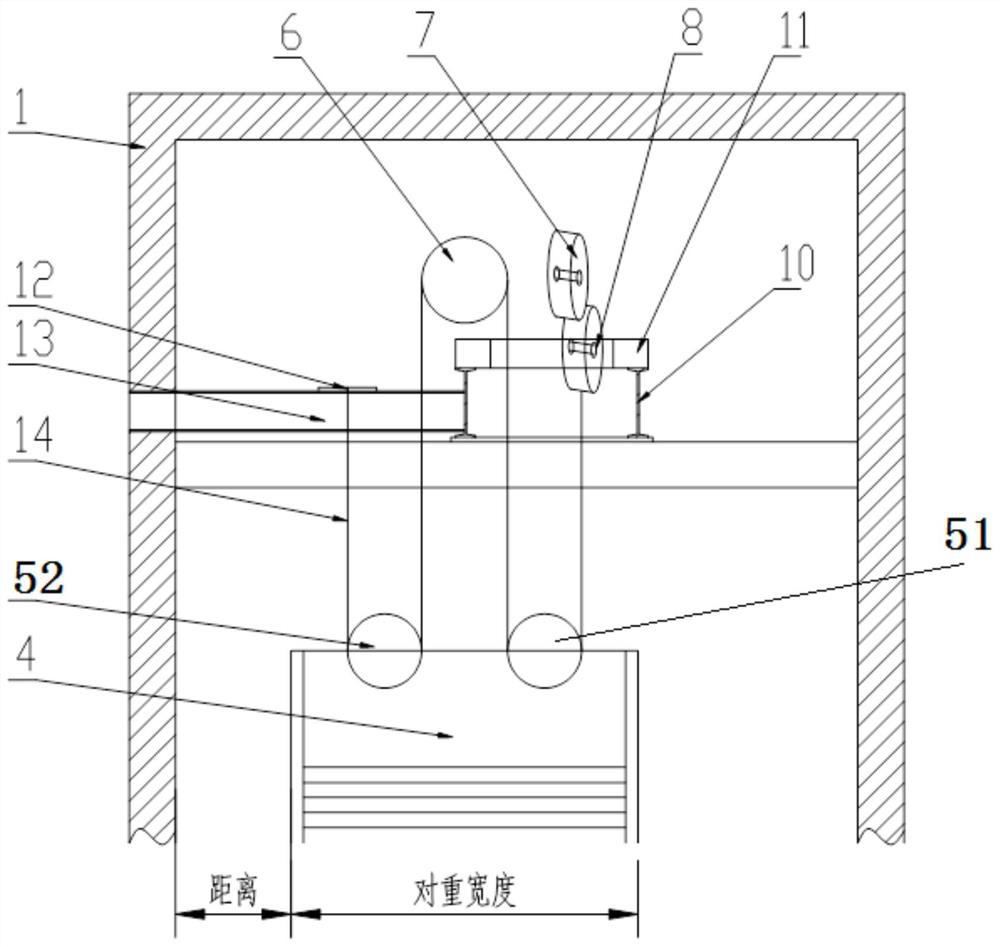

[0056] Based on the counterweight side-fall elevator structure of Embodiment 1, the traction machine wheel 7, the machine room guide wheel 8 and the traction machine are all fixed on the traction frame 11;

[0057] The first counterweight guide wheel (61) and the second counterweight guide wheel (62) are fixed on the hoistway wall or are fixed on the load-bearing beam (10) by a bracket.

[0058] Preferably, the traction wire rope 14 is suspended upward from the rope groove at the front side of the second pair of return sheaves 52 to the counterweight rope end plate 12 on the counterweight rope head bearing beam 13 .

[0059] Preferably, the distance between the first pair of heavy guide wheels 61 and the second pair of heavy guide wheels 62 is 1.1 to 1.5 times the thickness of the machine room guide wheels 8;

[0060] The far away car side rope groove of machine room guide wheel 8 penetrates between the first pair of heavy guide wheels 61 and the second pair of heavy guide whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com