A hydrogen production system with controllable aluminum-alkali reaction

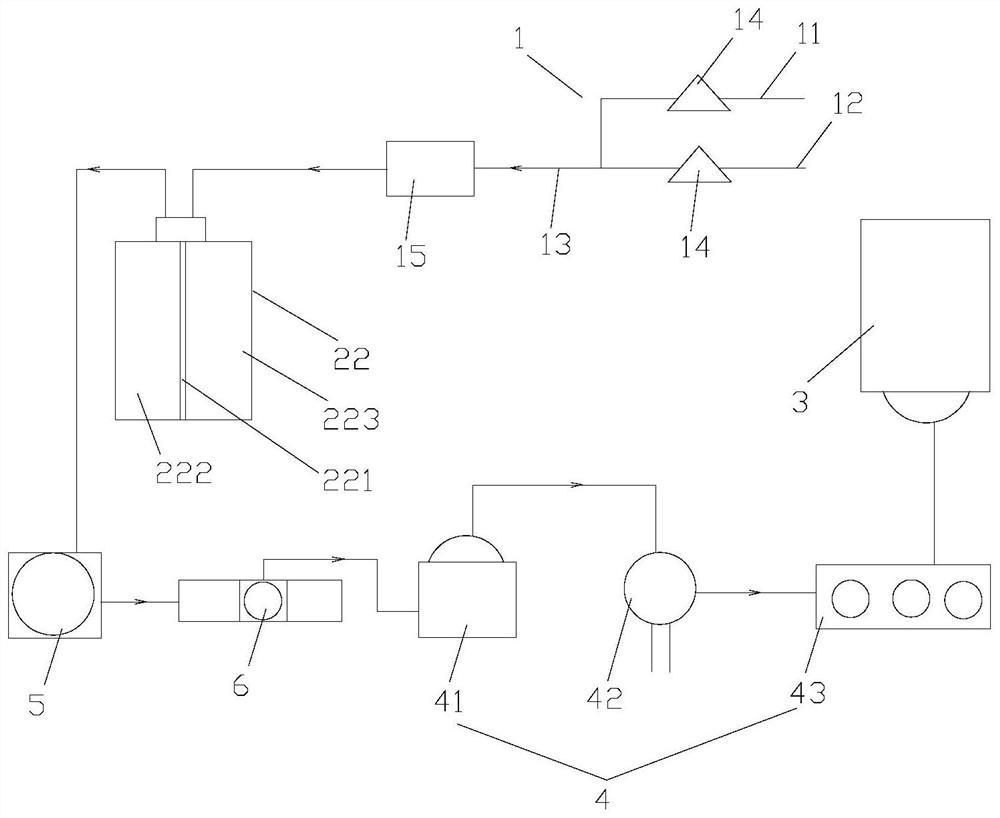

A hydrogen production system and reaction technology, applied in hydrogen production and other directions, can solve the problems of lack of buffer devices, high instantaneous pressure of hydrogen production, slow reaction time, etc., and achieve the effects of reducing resource consumption, reducing waste of raw materials, and short reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

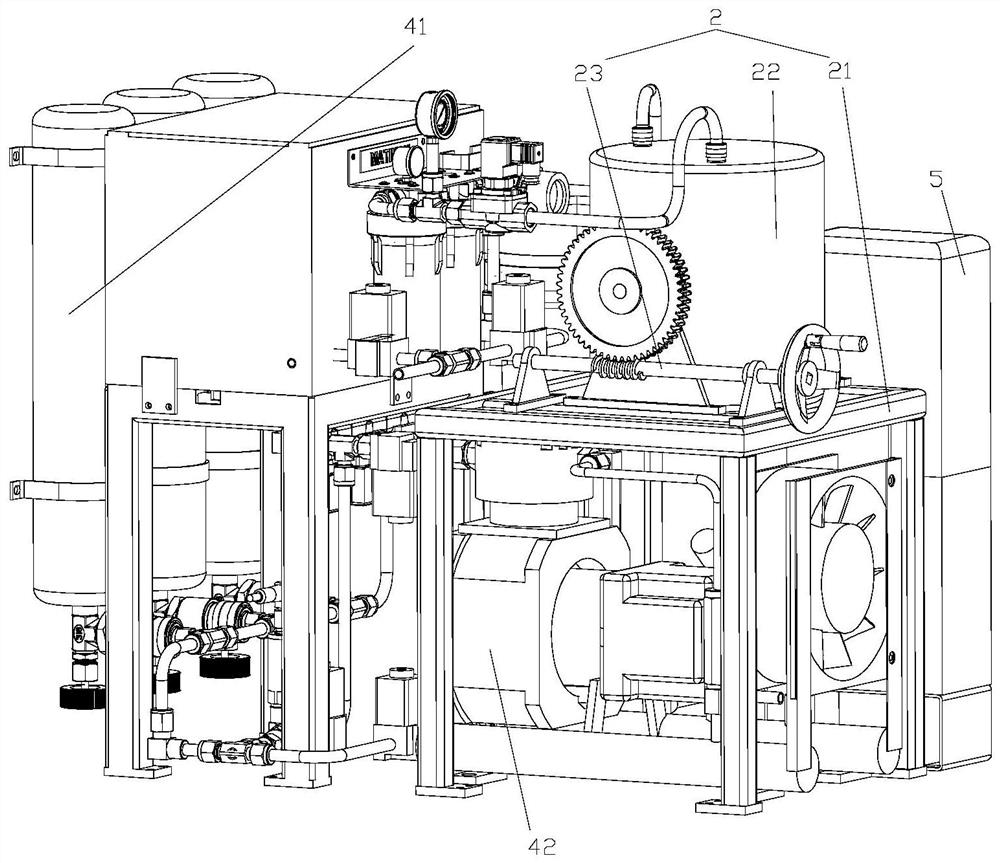

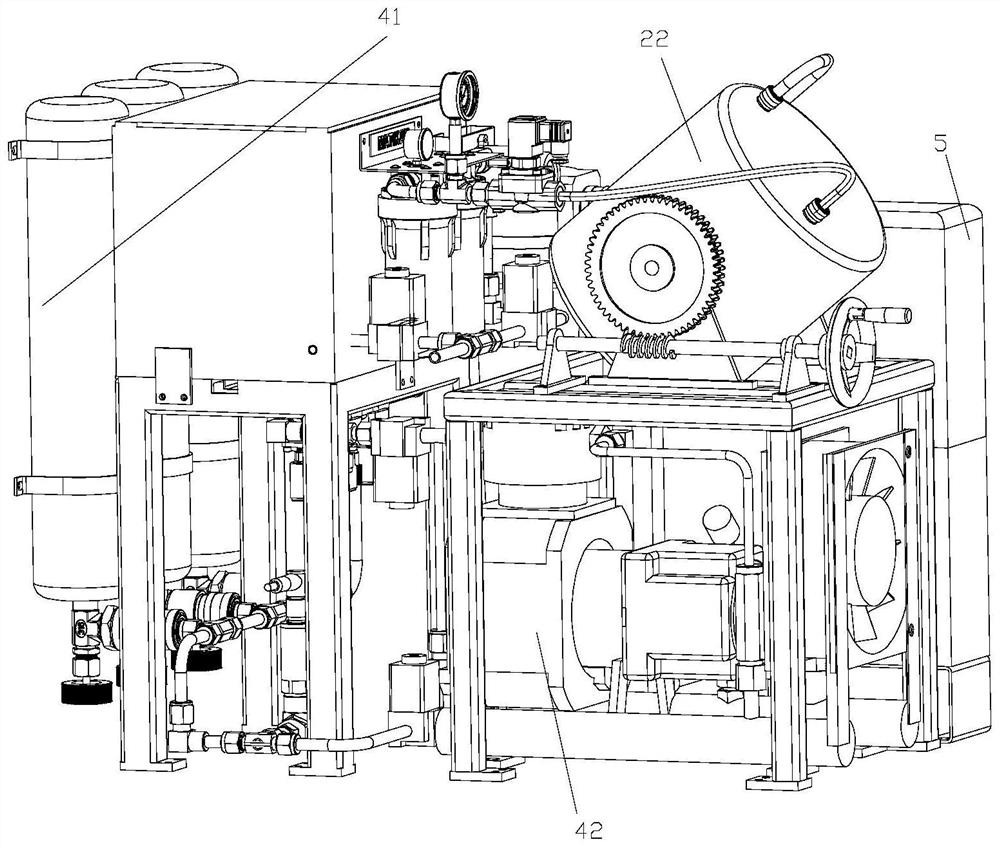

[0038] Embodiment 1: During the gas production operation, the turning mechanism 23 drives the reaction bottle 22 to be in an upright state, and the water injection device 1 injects water into the right chamber 223. The injected water will react with the alkali material and dissolve into alkaline water, and the alkaline water will pass through the osmotic barrier. The plate 221 quickly penetrates into the left chamber 222 and reacts with the aluminum powder quickly to generate hydrogen gas, which is collected by the collecting device 3 through the pipeline.

[0039] When it is necessary to stop gas production, the turning mechanism 23 drives the reaction bottle 22 in the upright state to turn over quickly, so that the left chamber 222 is on the top and the right chamber 223 is on the bottom of the non-upright state (such as image 3 Flip to the right as shown in). This non-upright state can be turned over 90 degrees, so that the left chamber 222 is completely on the top and the...

Embodiment 2

[0041] Embodiment 2: During the gas production operation, the turning mechanism 23 drives the reaction bottle 22 to be in an upright state, and the water injection device 1 injects water into the right chamber 223, and the injected water will react with the alkali material and dissolve into alkaline water. When the right chamber 223 was filled with water, the water would fully contact the alkali material in the right chamber 223 and complete a comprehensive reaction, so that the dissolved alkaline water had a higher purity (certainly, at this time, the same as in Example 1, it would still be Part of the alkaline water seeps into the left chamber 222). After being fully contacted and fully dissolved and reacted, the reaction bottle 22 in the upright state is driven by the turning mechanism 23 to turn over quickly (such as image 3 shown in the leftward direction), so that the right chamber 223 is on top and the left chamber 222 is on the bottom of the non-erect state. Compared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com