A method and device for controlling the start and stop of a mine belt conveyor along the coal flow

A belt conveyor, coal flow technology, applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problems of poor flexibility, inability to meet start-stop control, poor adaptability, etc., to speed up the start-stop control speed , Save the cost of equipment layout and ensure the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

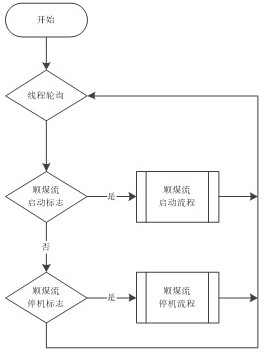

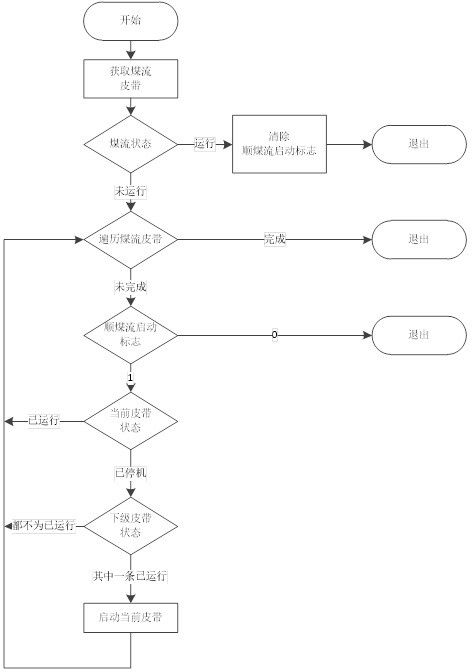

[0071] Such as figure 2 As shown, a mine belt conveyor start control method along the coal flow, comprising,

[0072] Classify the belts in each coal flow, the first belt in each coal flow is the belt of the upper level belonging to other coal flows, or the upper level belt in each coal flow is the belt of the third-party controller Belts, or belts without a previous belt in each coal stream;

[0073] In order to realize fast startup, during the startup process along the coal flow, the reverse query method is used, that is, the belt without the next-level belt is started first in the belt polling process. In addition, the coal flow start sign is used to indicate the start of the coal flow. For the convenience of memory, the start sign of the coal flow in this embodiment is represented by the number 1 (those skilled in the art can also use any other mark that is easy to remember).

[0074] In order to avoid garbled codes during function execution, and to ensure that the belt...

Embodiment 2

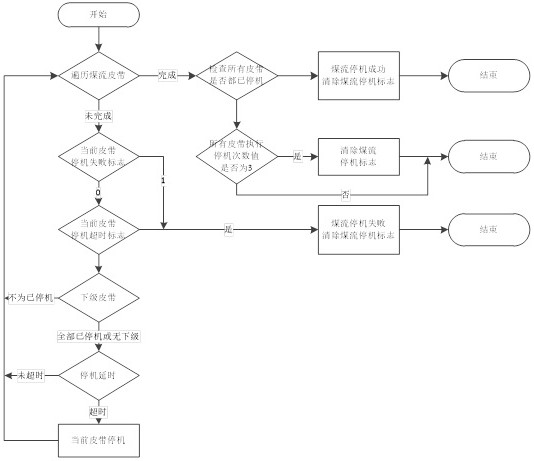

[0272] Such as image 3 As shown, a mine belt conveyor shutdown control method along the coal flow, corresponding to start along the coal flow, including,

[0273] The downtime sign of the coal flow is used to indicate that the coal flow is in the process of being shut down, and the present embodiment adopts the number 1 to represent it.

[0274] The stop failure flag is used to record that the running belt has failed to stop; by definition, the stop failure means that the running belt has not completed the stop process for more than the set number of times, and exits the coal flow stop function;

[0275] The stop overtime mark is used to record that the belt in the running stop has stopped for more than the preset time, and the stop overtime time is set as an empirical value, and can also be set according to actual needs;

[0276] The coal flow shutdown function traverses the coal flow belt, checks whether there is a shutdown failure flag or a shutdown timeout flag on the ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com