Assembly type buffering beam falling prevention device

An anti-fall beam and assembled technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems that the anti-fall beam facilities are easily damaged and difficult to replace, and achieve the effect of simple maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

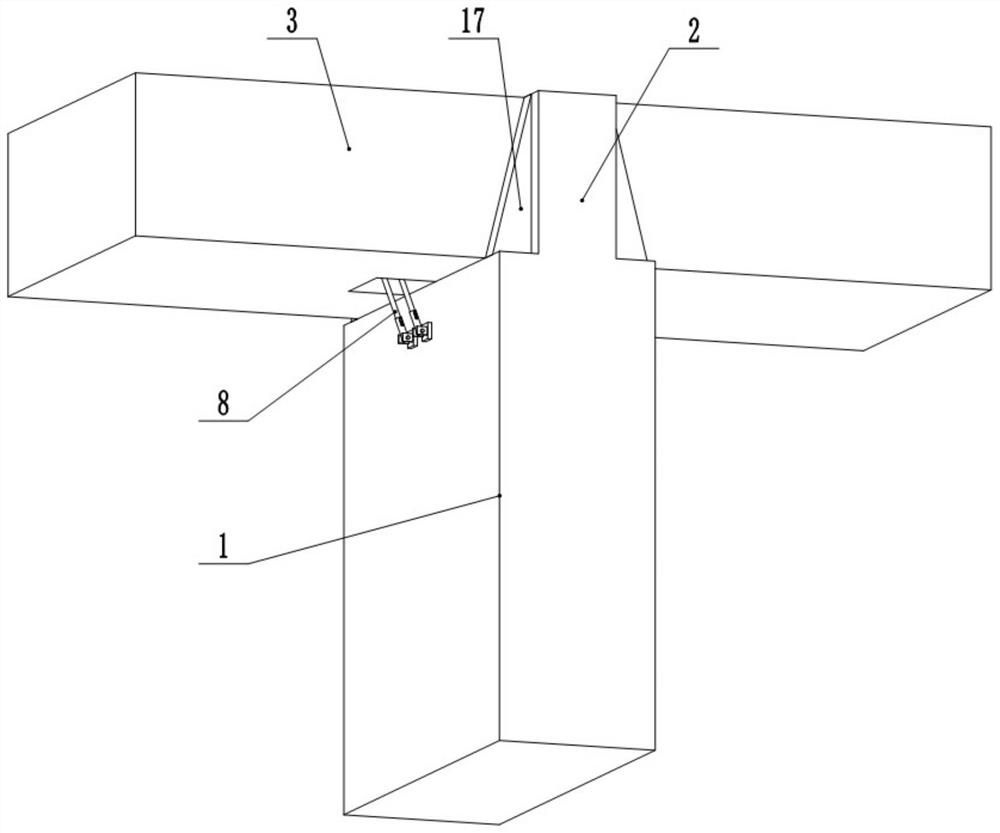

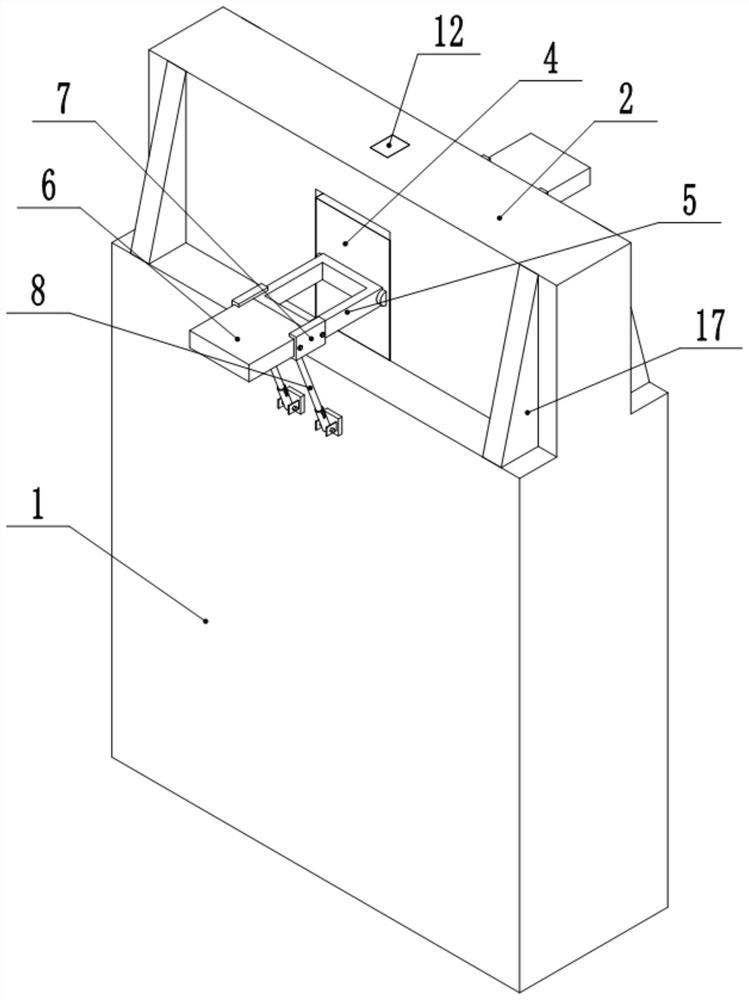

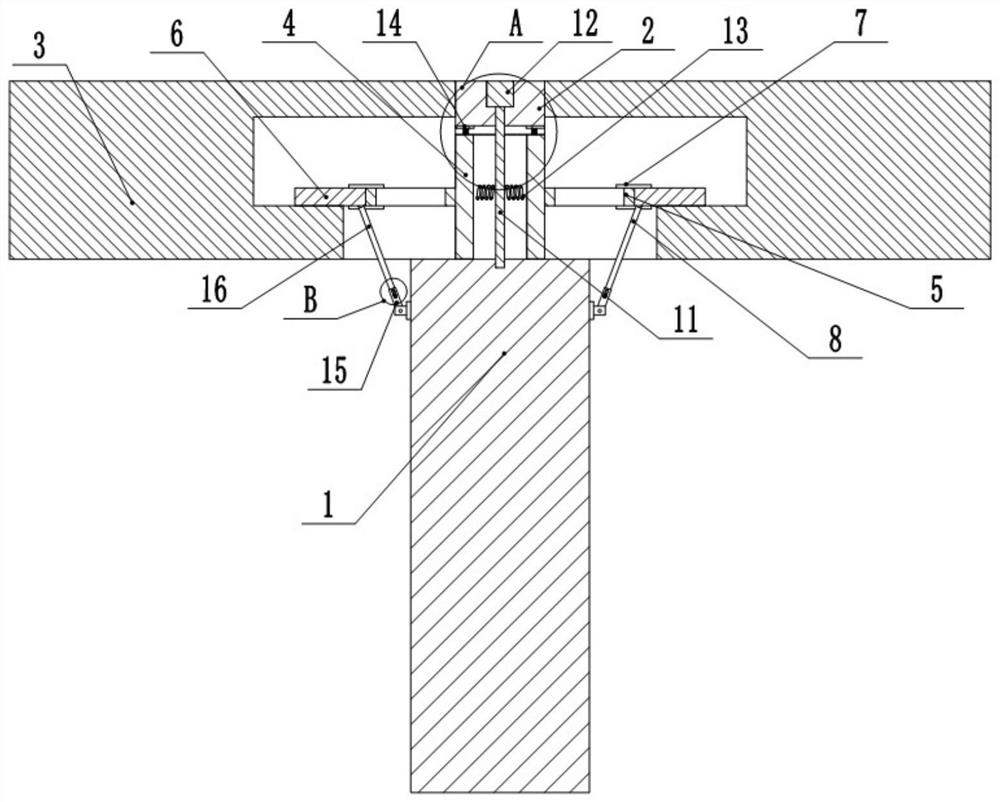

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 Shown:

[0025] An assembled buffer anti-fall beam device, comprising a bridge pier 1, a vertically arranged anti-collision plate is fixed on the top of the bridge pier 1, the anti-collision plate coincides with the center line of the bridge pier 1, and fixed frames 5 are symmetrically arranged on both sides of the anti-collision plate, and fixed The movable end of the frame 5 is hinged with a connecting plate; two beams 3 are symmetrically arranged on the pier 1, and the end faces of the beams 3 are provided with a chamber for accommodating the connecting plate, and the bottom wall of the chamber is provided with an entrance, and the width of the entrance is larger than Width of the connecting plate and the fixed frame 5, the connecting plate is hinged with a connecting rod 8, the connecting rod 8 is a spring telescopic rod, and the movable end of the connecting rod 8 stretches out from t...

specific Embodiment approach

[0026] The positioning block 4 is installed in the cavity, the positioning column 11 is inserted in the concave cavity, and the cover plate 12 is covered to complete the installation of the positioning block 4; the fixing frame 5 and the connecting plate are installed on the side wall of the positioning block 4, Fold the connecting plate and the fixing frame 5; then place the beam body 3 on the pier 1.

[0027] Stretch the connecting rod 8 again, put the fixed frame 5 and the connecting plate flat, make the connecting plate stretch into the beam body 3 chamber and be close to the bottom wall of the chamber, and connect the clamping block 7 to the hinge between the connecting plate and the fixed frame 5 place, and use bolts to fix the block 7, detachably hinge the connecting rod 8 and the pier 1; connect the hydraulic damper 9 and the limit block 10 to the side wall of the connecting plate respectively.

[0028] During an earthquake, when the beam body 3 is displaced laterally,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com