Construction method of prefabricated underwater tie beam

A prefabricated assembly and construction method technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve problems such as potential safety hazards, damage to waterproof measures of casings, deformation of joints, etc., to ensure project quality and improve overall waterproof performance , Guarantee the effect of verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

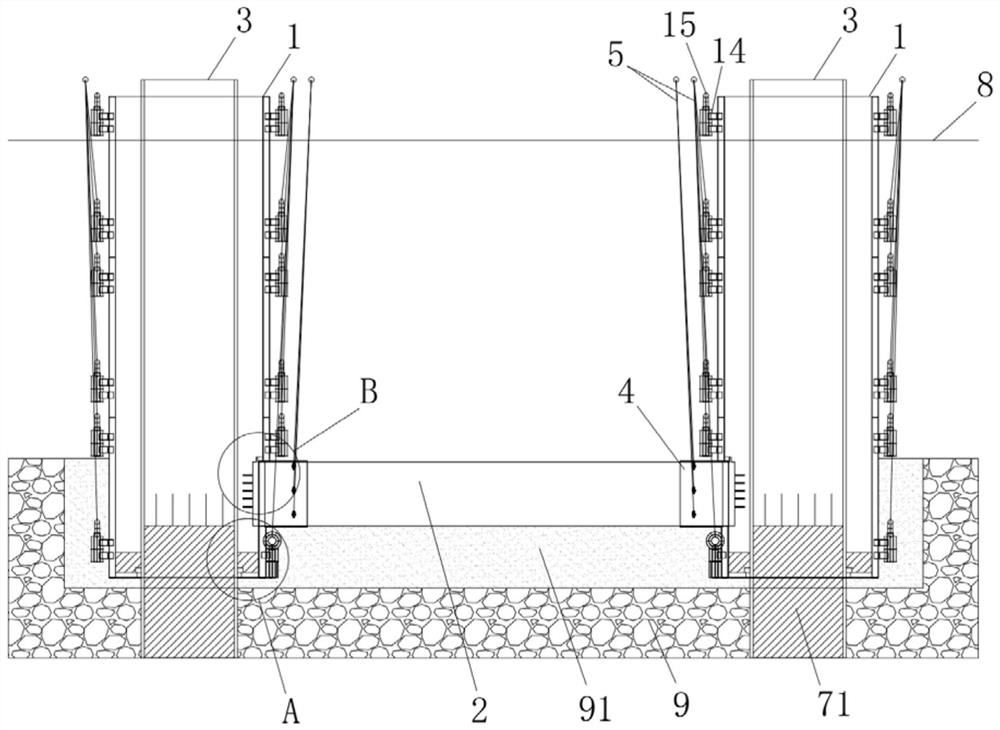

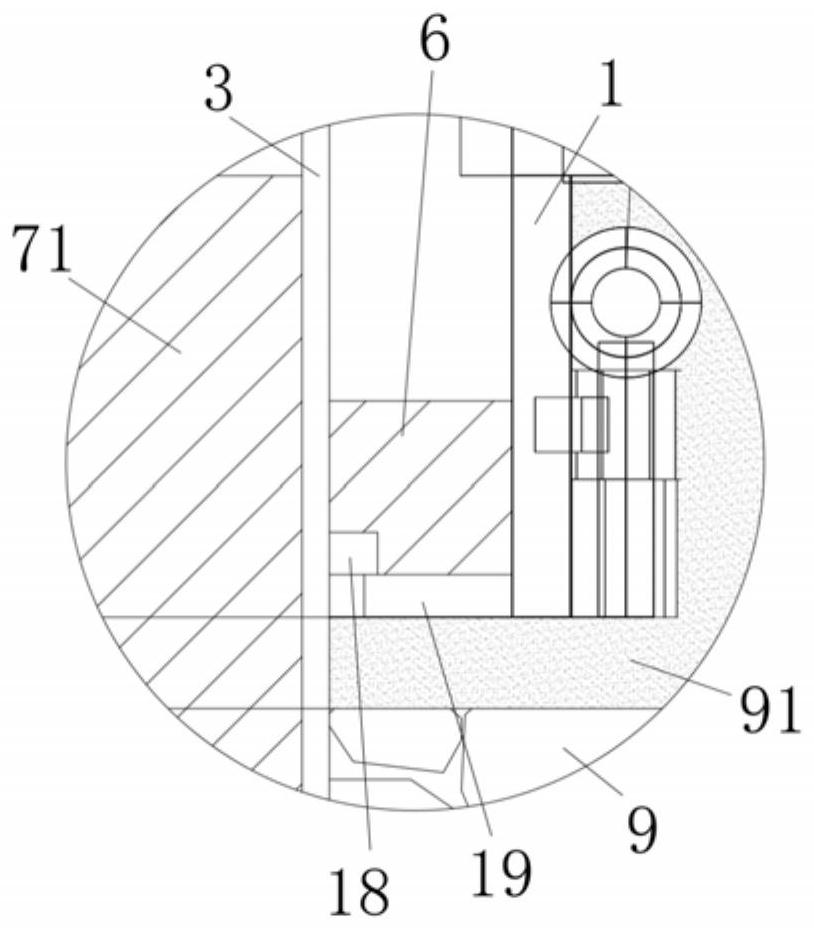

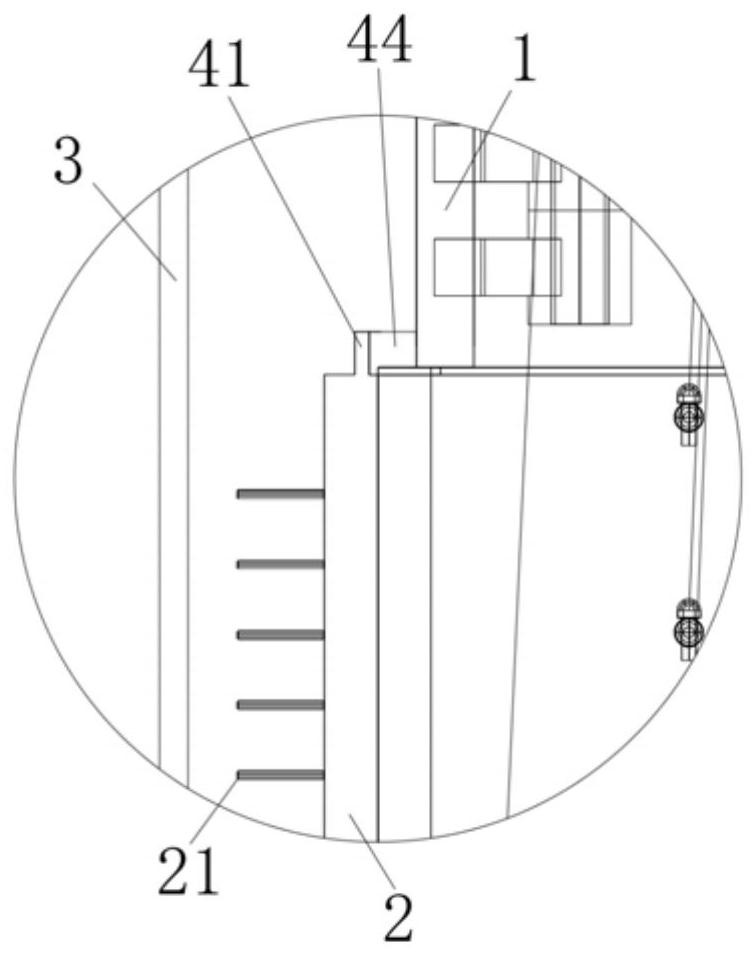

[0039] In order to make the purpose, technical solution and advantages of the present invention clearer, a construction method of a prefabricated underwater tie beam will be described more clearly and completely below in conjunction with the accompanying drawings in the embodiments of the present invention. The preferred embodiment of the construction method of the prefabricated underwater tie beam is given in the accompanying drawings, however, the construction method of the prefabricated underwater tie beam can be implemented in many different forms and is not limited to the implementation described herein example. On the contrary, the purpose of providing these embodiments is to make the disclosure of the construction method of the prefabricated underwater tie beam more thorough and comprehensive.

[0040] It should be noted that like numerals and letters denote similar items in the following figures, therefore, once an item is defined in one figure, it does not require furth...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap