Cast-in-situ bored pile structure and construction method thereof

A technology of bored piles and steel casings, which is used in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of casing shaking, casing deviation, affecting the overall shape of the cast-in-place piles, and reducing manual operations. , reduce the effect of shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

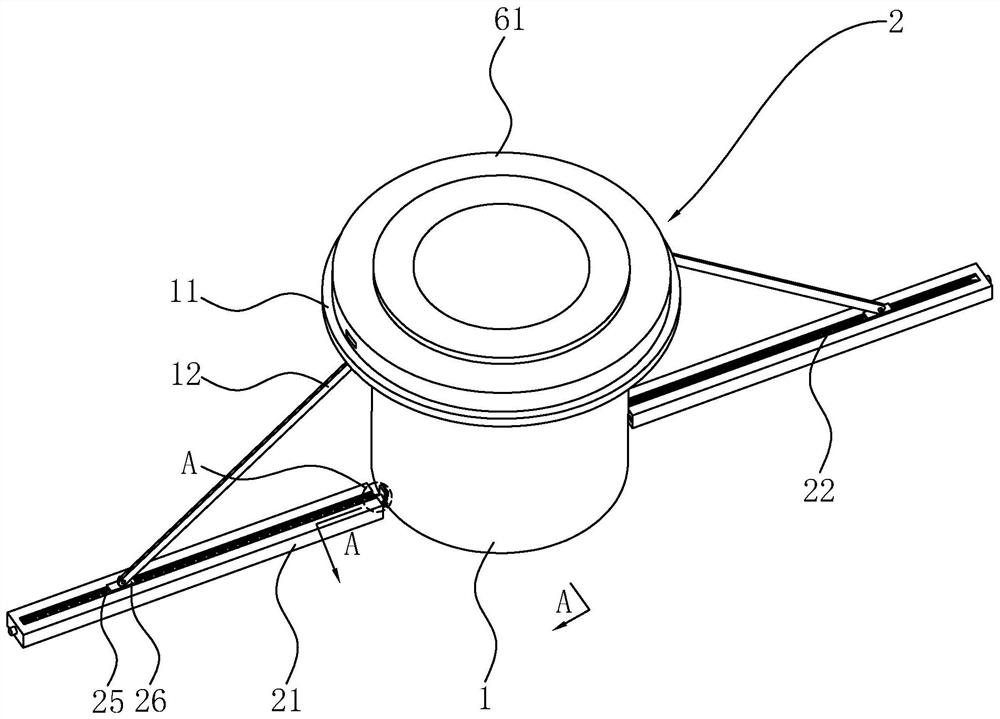

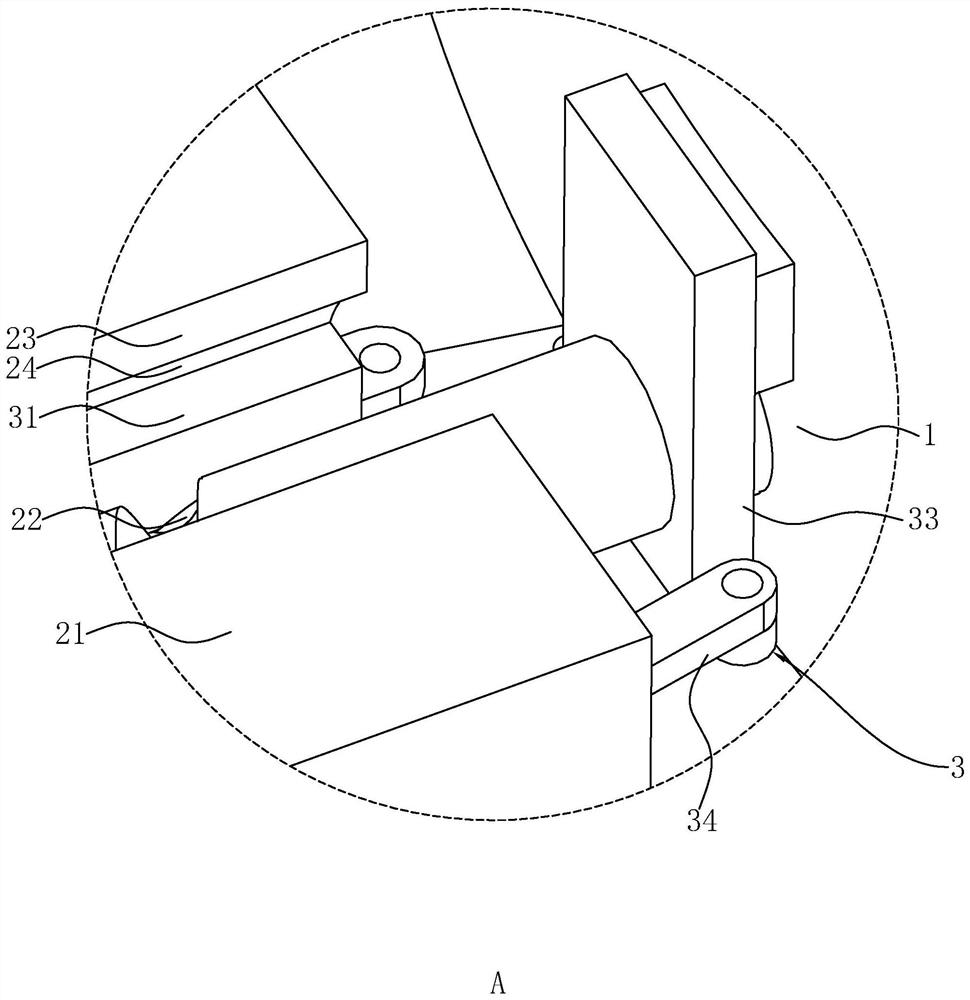

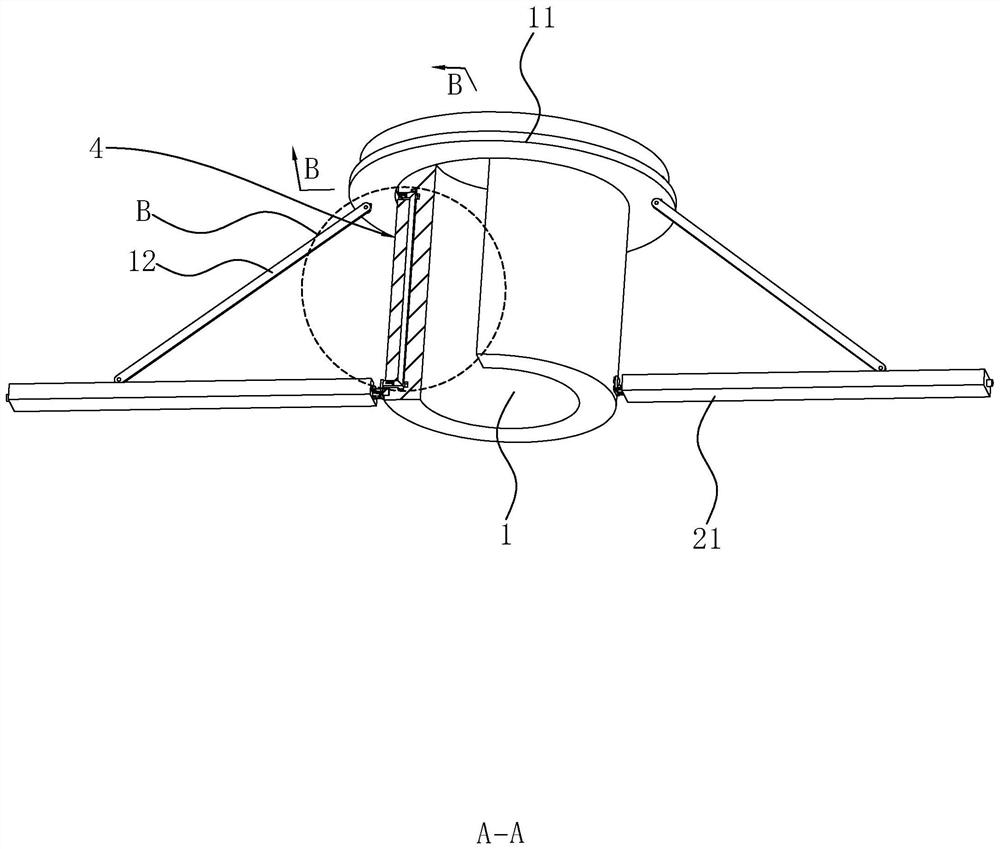

[0043] refer to figure 1 with figure 2A bored pile structure includes a steel casing, a support ring 11 vertically slidably arranged on the outer peripheral surface of the steel casing 1, and two struts 12 hinged to the bottom surface of the support ring 11 respectively. A fixing ring 61 is fixed on the top of the steel casing 1 , and two sets of connection assemblies 6 for fixedly connecting the supporting ring 11 and the fixing ring 61 are arranged between the supporting ring 11 and the fixing ring 61 . Both sides of the steel casing 1 are respectively provided with driving mechanisms 2 for driving the support ring 11 to move upward. Each group of driving mechanisms 2 includes a guide rail 21 arranged on one side of the steel casing 1 and a lead screw 22 penetrating in the guide rail 21 and rotatably connected to the end of the guide rail 21 away from the steel casing 1 . The top of the guide rail 21 is provided with a guide rail groove 23 , and the two sides of the guide...

Embodiment 2

[0056] A construction method for bored piles, comprising the steps of:

[0057] S1. Clean up the ground and compact the position where the cast-in-situ pile needs to be formed;

[0058] S2. Drill a hole with a depth of 3m and bury the steel casing 1. Before the steel casing 1 is buried, set the support ring 11 on the side of the steel casing 1. The inner diameter of the steel casing 1 is selected to be 30cm larger than the pile diameter;

[0059] S3. Laying guide rails 21 on both sides of the steel casing 1, rotating the guide rails 21, so that the support ring 11 rises to contact with the fixed ring 61, and the support ring 11 and the fixed ring 61 are fixedly connected by the connection assembly 6;

[0060] S4. Install a reinforcement cage in the steel casing 1, pour concrete after installation, and take out the steel casing 1 after the concrete has solidified.

Embodiment 3

[0062] A construction method for bored piles, comprising the steps of:

[0063] S1. Clean up the ground and compact the position where the cast-in-situ pile needs to be formed;

[0064] S2. Drill a hole with a depth of 2m and bury the steel casing 1. Before the steel casing 1 is buried, set the support ring 11 on the side of the steel casing 1. The inner diameter of the steel casing 1 is selected to be 20cm larger than the pile diameter;

[0065] S3. Laying guide rails 21 on both sides of the steel casing 1, rotating the guide rails 21, so that the support ring 11 rises to contact with the fixed ring 61, and the support ring 11 and the fixed ring 61 are fixedly connected by the connection assembly 6;

[0066] S4. Install a reinforcement cage in the steel casing 1, pour concrete after installation, and take out the steel casing 1 after the concrete has solidified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com