Apparatus and method for clamping and picking up silicon wafers stored in wafer cassettes, and silicon wafer transfer equipment

A silicon wafer box and silicon wafer technology, applied in the direction of conveyor objects, transportation and packaging, electrical components, etc., can solve the problem of simultaneous or one-time transmission, four silicon wafers cannot be transmitted at the same time or one-time transmission, equipment 10A work efficiency reduction and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

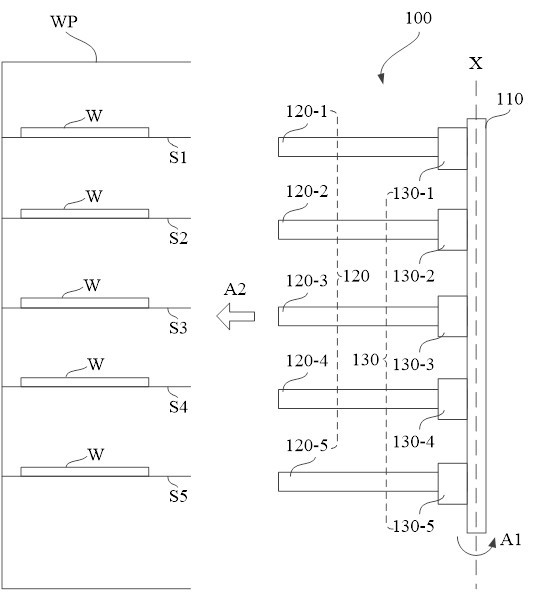

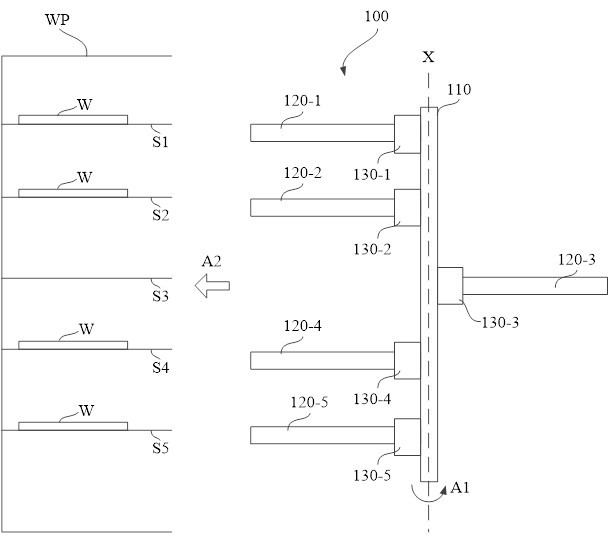

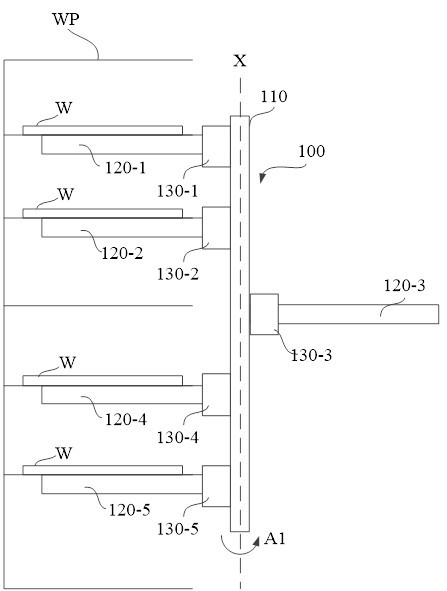

[0034] see figure 2 , an embodiment of the present invention provides a device 100 for clamping a wafer W stored in a wafer cassette WP, wherein, figure 2 It is exemplarily shown that five silicon wafers W are placed in the first to fifth continuous slots S1-S5 of the wafer box WP from top to bottom, and the device 100 may include:

[0035] drive shaft 110, said drive shaft 110 being able to rotate around its own longitudinal axis X, as in figure 2 Schematically shown by arrow A1 in ;

[0036] a plurality of clamping arms 120 arranged on the drive shaft 110, figure 2exemplarily shows the first to fifth gripping arms 120-1 to 120-5 respectively corresponding to the first to fifth slots S1-S5, and the plurality of gripping arms 120 are along the direction perpendicular to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com