Stirring equipment for chemical processing

A mixing equipment and chemical technology, which is applied in the field of mixing equipment for chemical processing, can solve problems such as poor heat dissipation, achieve the effects of maintaining stable internal temperature, avoiding processing hazards, and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

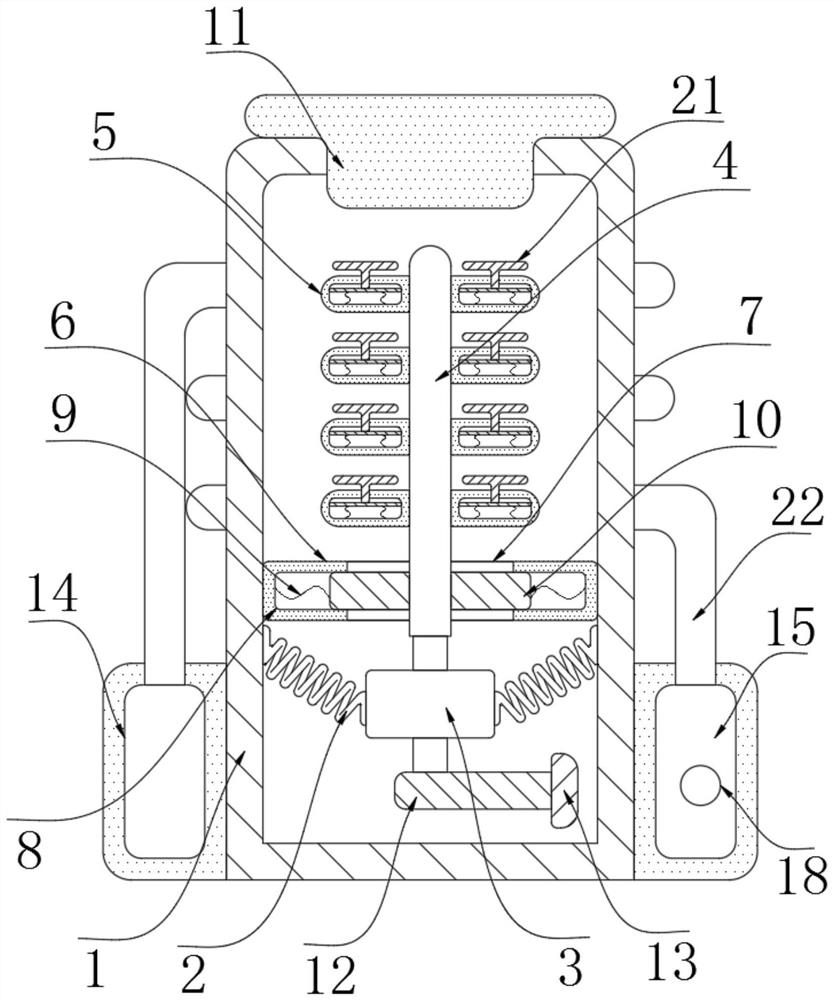

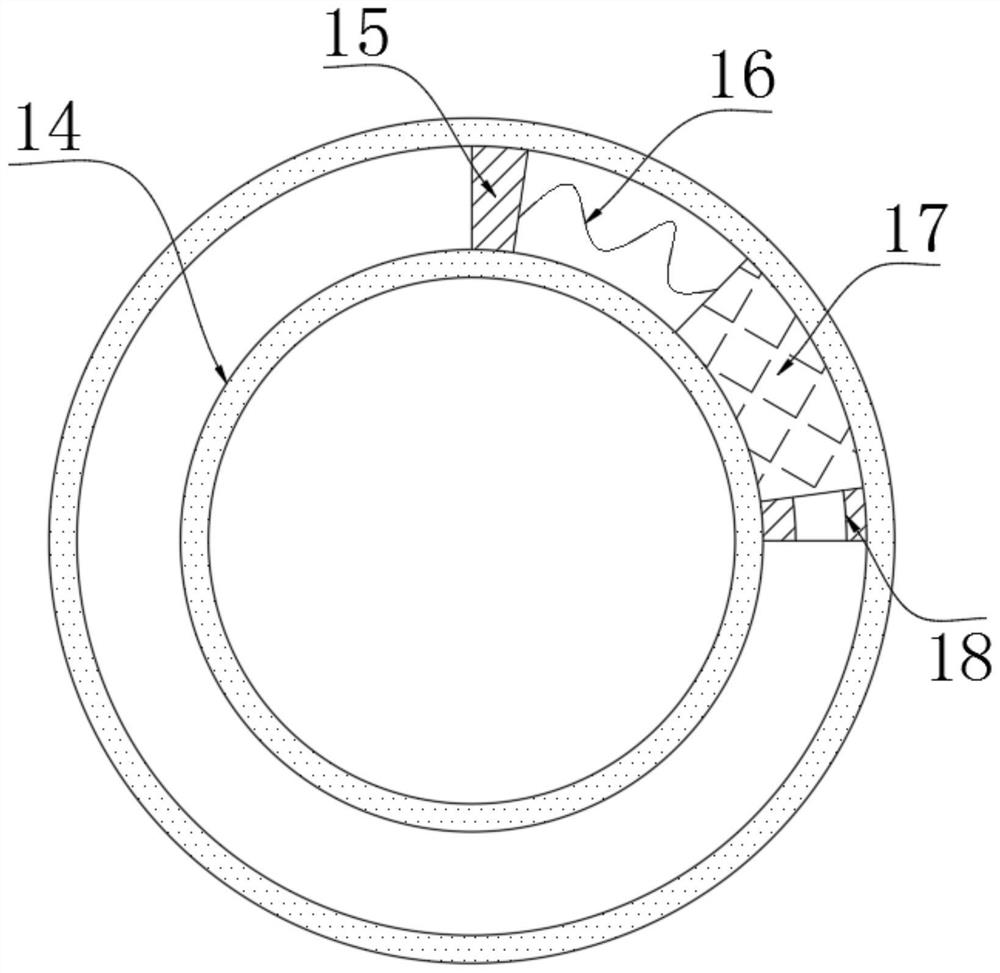

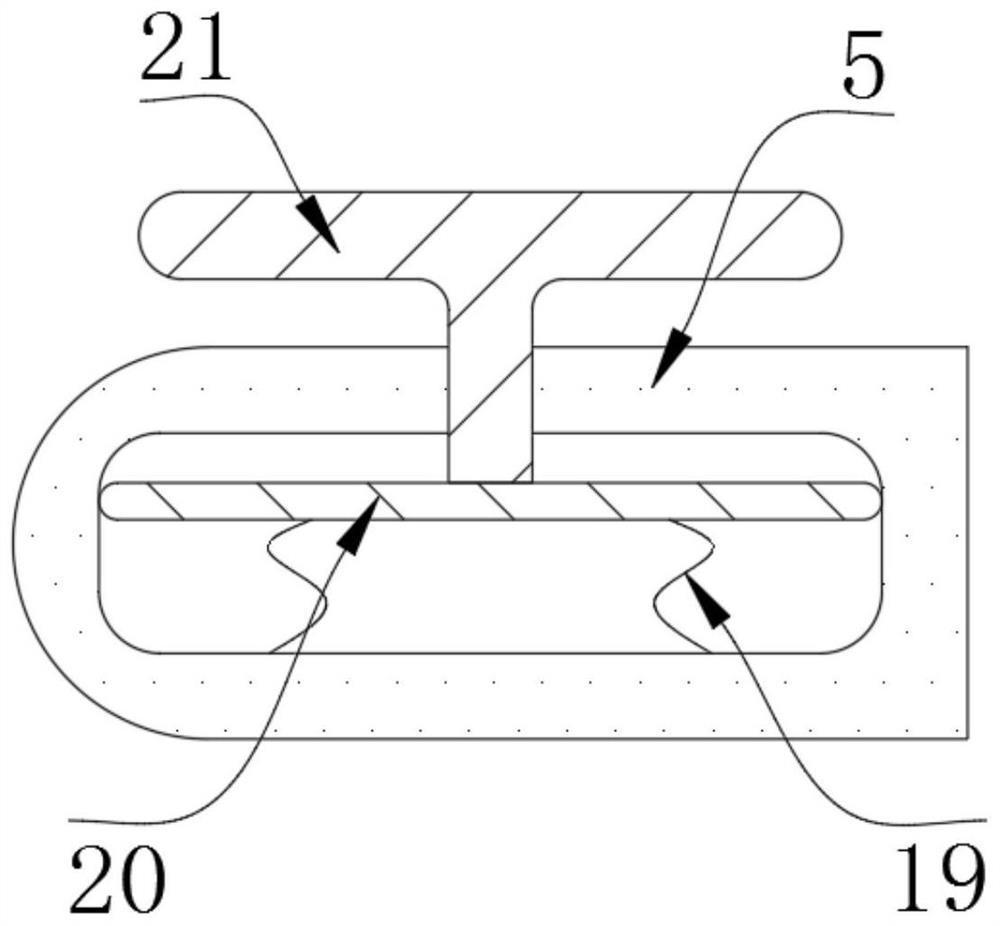

[0019] refer to Figure 1-3 , a stirring device for chemical processing, comprising a stirring box 1, the lower inner wall of the stirring box 1 is fixedly connected with a motor 3 through a plurality of connection springs, the output shaft at the upper end of the motor 3 is fixed with a stirring column 4, and the circumferential side of the stirring column 4 A plurality of stirring rods 5 are fixed on the wall, and each stirring rod 5 is provided with a shaking addition mechanism inside. The upper opening of the stirring box 1 is equipped with a closing cover 11, and the inner wall of the stirring box 1 is fixed with a partition 6, and the partition 6 The upper end is penetrated with a vibration groove 7, and the inner wall of the vibration groove 7 is provided with a chute 8, and the inner wall of the chute 8 is jointly connected with a slide plate 10 through a plurality of buffer springs 9, and the stirring column 4 is connected with the slide plate 10 through rotation, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com