Production technology of wear-resistant aluminum alloy door and window

A technology for aluminum alloy doors and windows and production process, which is applied to the device for coating liquid on the surface, pretreatment surface, coating and other directions, can solve the problems of scratches on aluminum alloy doors and windows, dull surface of aluminum alloy doors and windows, uneven structure, etc. To achieve the effect of reducing the connection hierarchy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

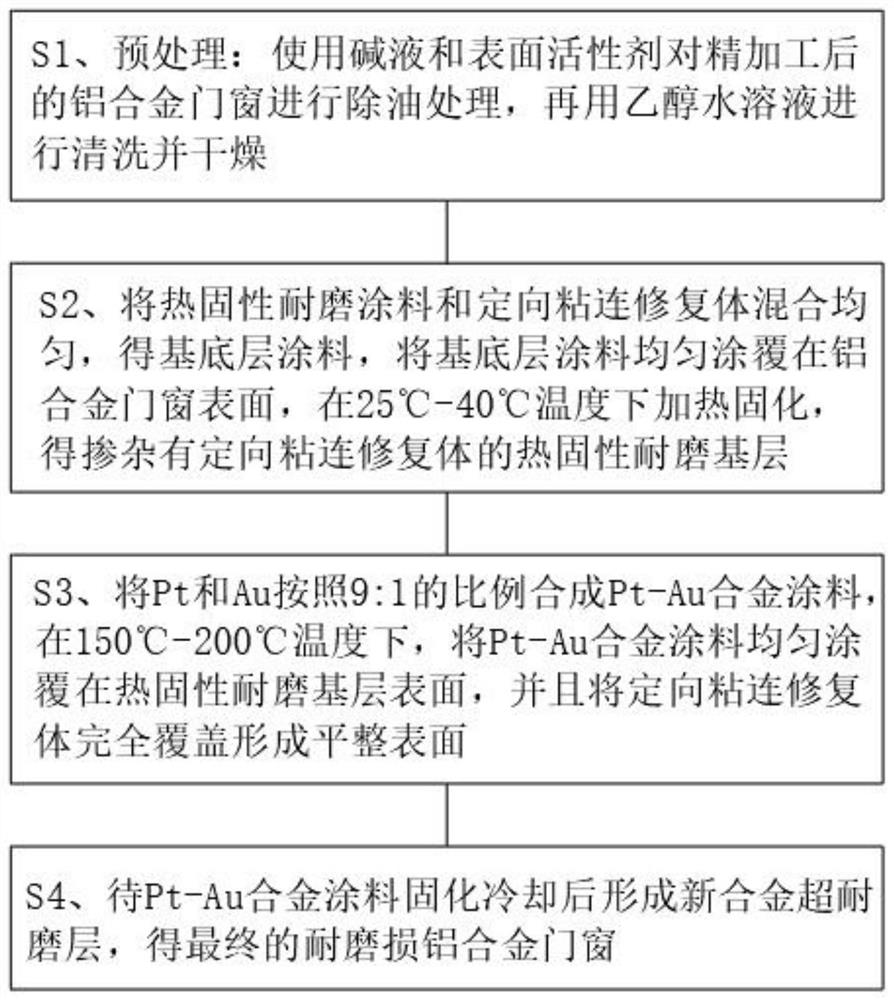

[0043] see figure 1 with figure 2 , a production process of wear-resistant aluminum alloy doors and windows, comprising the following steps:

[0044] S1. Pretreatment: Use lye and surfactant to degrease the finished aluminum alloy doors and windows, then clean and dry with ethanol aqueous solution;

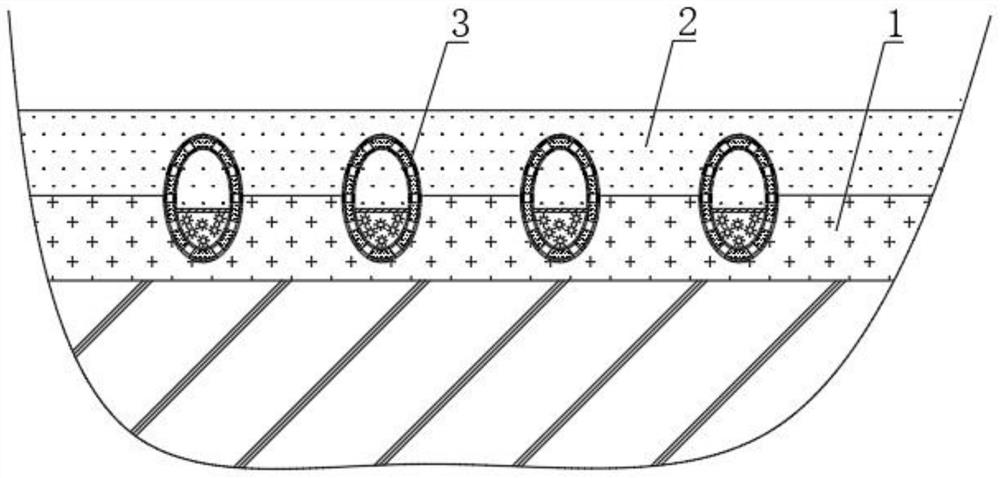

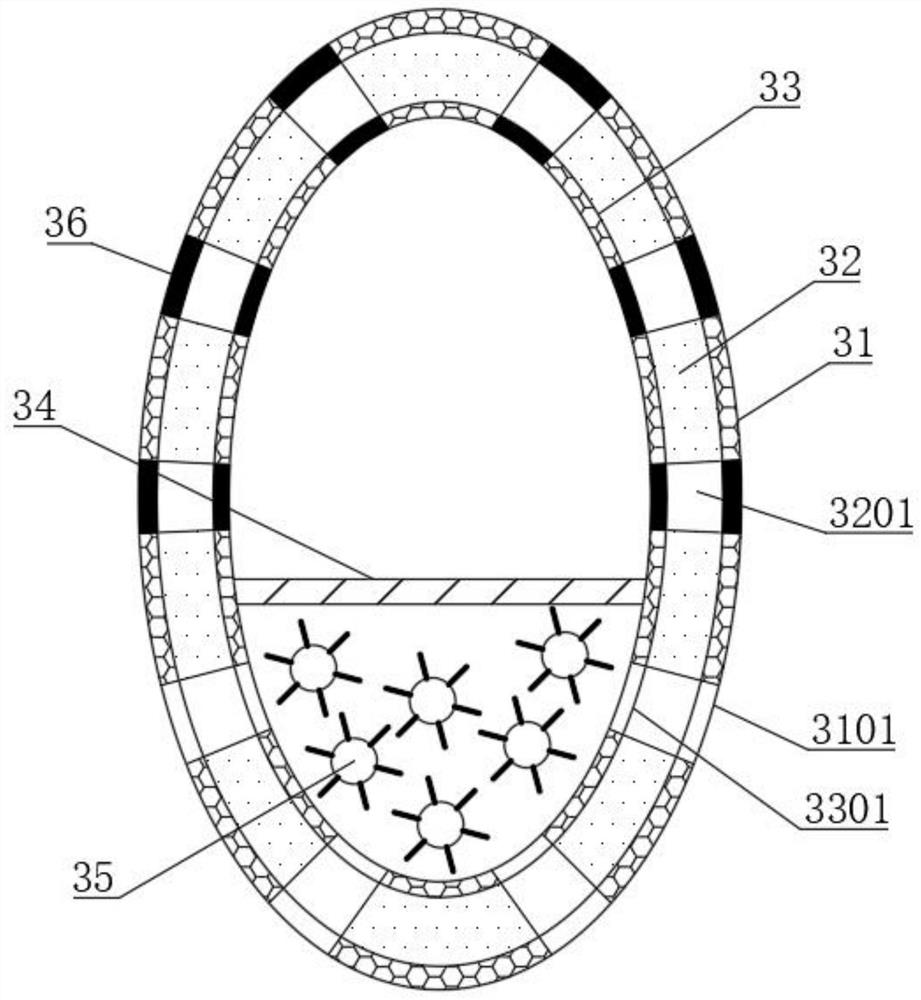

[0045] S2. Mix the thermosetting wear-resistant coating and the directional adhesion prosthetic 3 evenly to obtain the base layer coating, uniformly coat the base layer coating on the surface of aluminum alloy doors and windows, heat and cure at 25°C-40°C, and obtain the oriented The thermosetting wear-resistant base layer 1 of the adhesion restoration 3;

[0046] S3. Synthesize Pt-Au alloy coating with Pt and Au at a ratio of 9:1, and evenly coat the Pt-Au alloy coating on the surface of the thermosetting wear-resistant base layer 1 at a temperature of 150°C-200°C, and repair the directional adhesion The body 3 is completely covered to form a flat surface;

[0047] S4. After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com