Synchronous powder feeding device for double-powder embedded type pressed parts

A synchronous powder feeding and inlay technology, which is applied in the direction of presses, manufacturing tools, material forming presses, etc., to achieve the effect of simple structure and convenient and quick powder feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

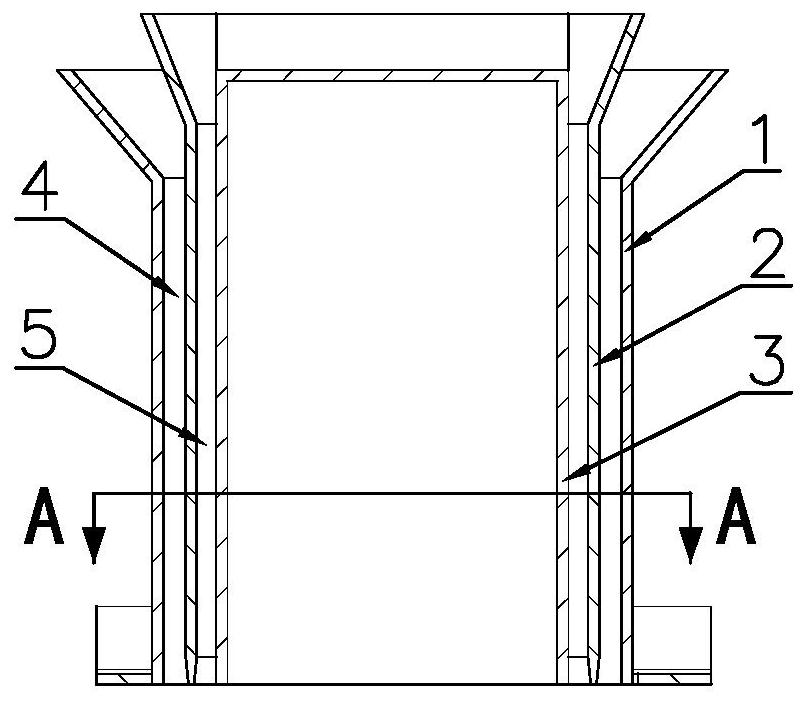

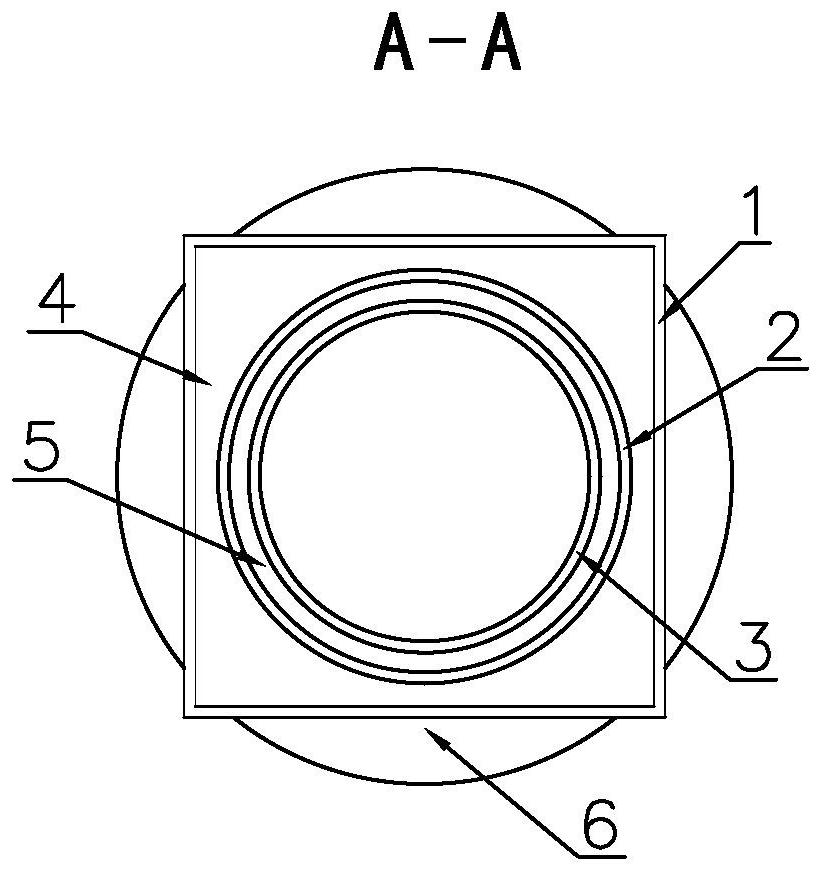

[0017] Embodiment 2: The difference from Embodiment 1 is that the cross section of the first feed chamber 4 is square on the outside and circular on the inside.

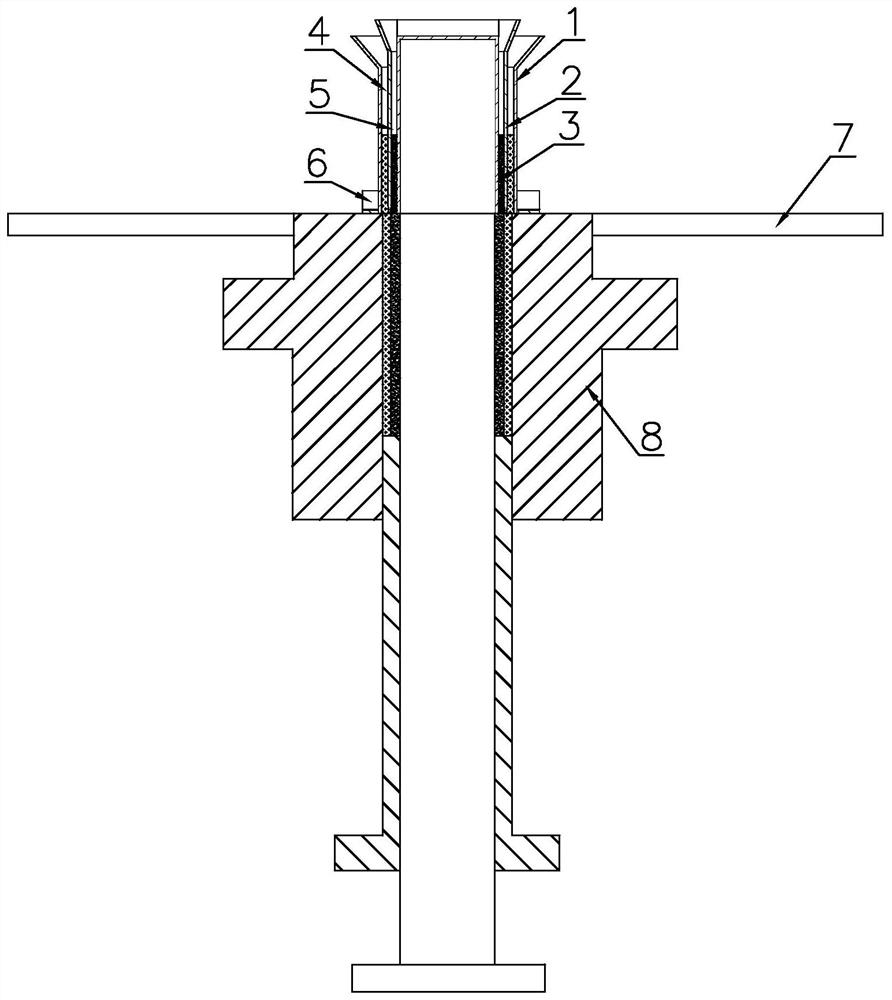

[0018] The method of use of the present invention is as follows: place the synchronous powder feeding device of the double-powder mosaic pressed part on the powder feeding operation table 7 of the tablet machine, and move the powder feeding device from the operation table 7 to the middle mold 8 when adding powder Above the mold cavity, the first feeding cavity and the second feeding cavity are aligned with the cavity of the middle mold 8 before feeding, and after the feeding is completed, the powder feeding device is moved to the operating platform 7 in translation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com