Novel low-resistance bilge keel structure of maritime work auxiliary ship

A bilge keel and auxiliary ship technology is applied in the field of low-resistance bilge keel structures of new marine auxiliary ships, which can solve the problems of increased resistance, complex navigation and working conditions, and inconsistent hull surface streamlines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

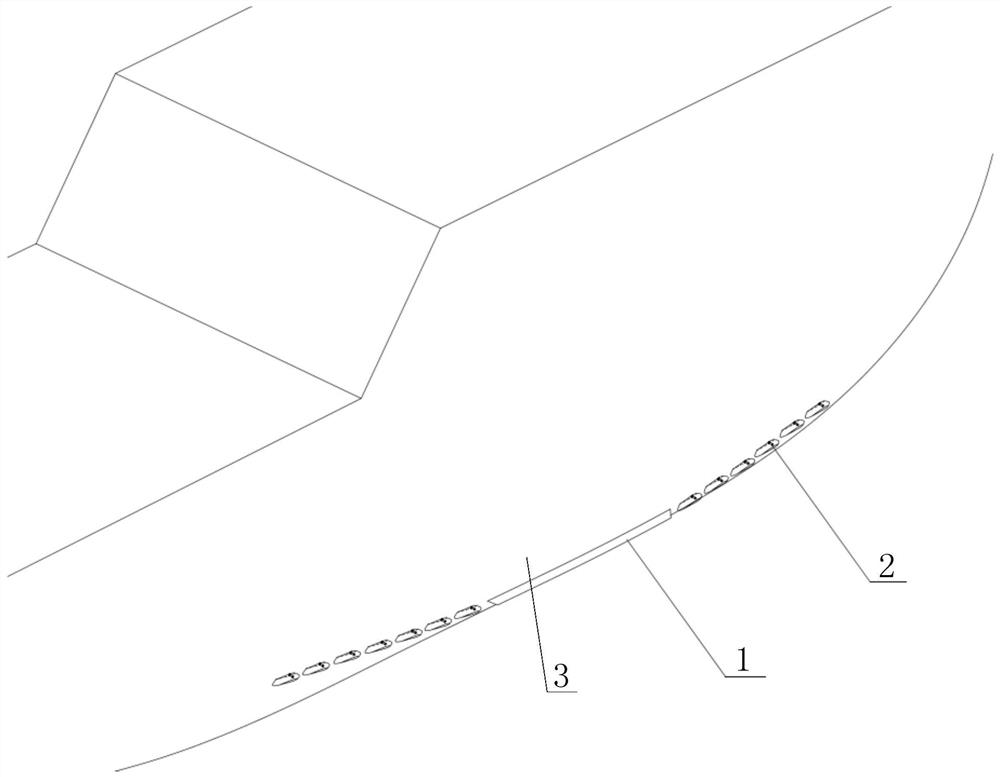

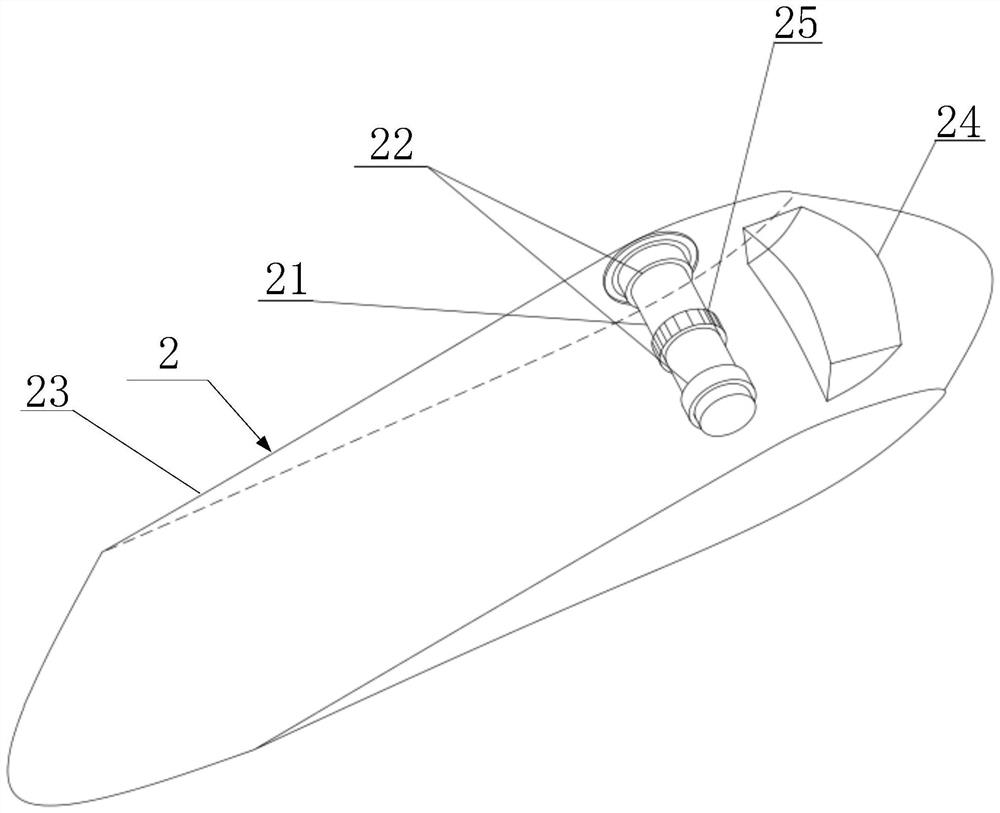

[0016] Below according to the attached figure 1 with figure 2 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and characteristics of the present invention can be better understood.

[0017] see figure 1 , a new low-resistance bilge keel structure of an auxiliary marine vessel according to an embodiment of the present invention includes a conventional bilge keel 1 fixed to the bilge portion of a hull 3 and a plurality of discrete leaf-shaped rotatable bilge keels 2 .

[0018] In this embodiment, the conventional bilge keel 1 is arranged in the middle section of the bilge of the hull 3 or the part where the streamlines of the bilge have no difference under various working conditions as proved by CFD calculation or model experiment.

[0019] The discrete leaf-shaped rotatable bilge keel 2 is arranged at the part where the streamlines of the bilge are different under various working conditions as proved by CFD calcu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotatable angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com