Tailstock type vertical take-off and landing unmanned aerial vehicle and control method thereof

A technology for vertical take-off and landing and unmanned aerial vehicles, which is applied in the field of aviation aircraft and unmanned aerial vehicles, and can solve the problems of increasing the resistance of unmanned aerial vehicles, radar reflection cross section, large space and specific gravity, and complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

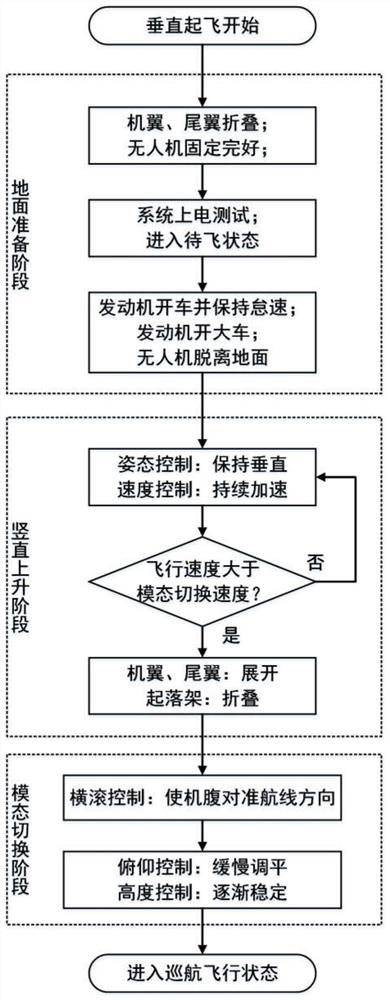

[0033] The invention proposes a tailseat type vertical take-off and landing unmanned aerial vehicle and its control method. The unmanned aerial vehicle can give full play to the vertical The take-off and landing function and the high-speed cruise function of the fixed wing provide technical support for safe take-off and landing in complex environments such as seas and mountains. The specific implementation method is as follows:

[0034] The specific implementation is as follows:

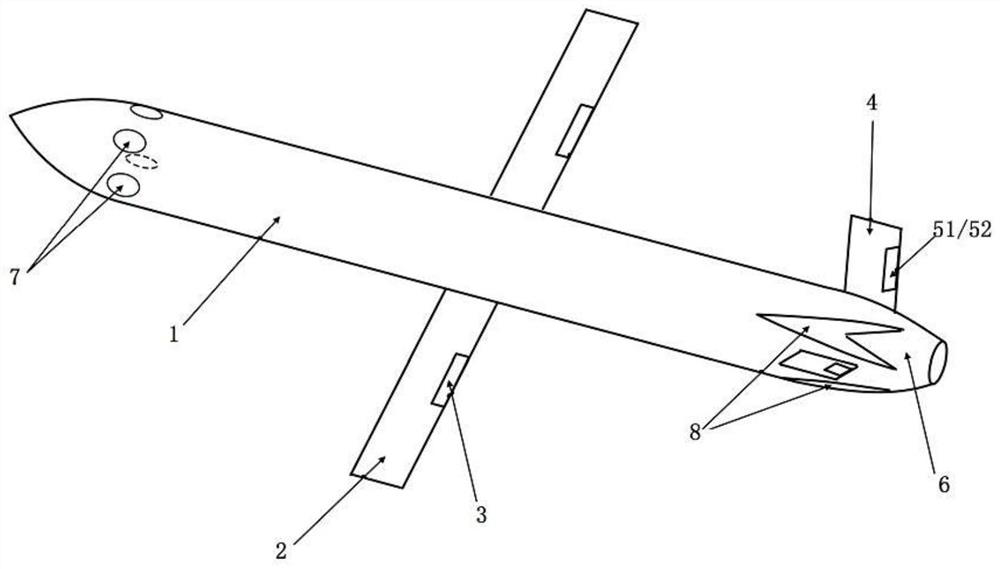

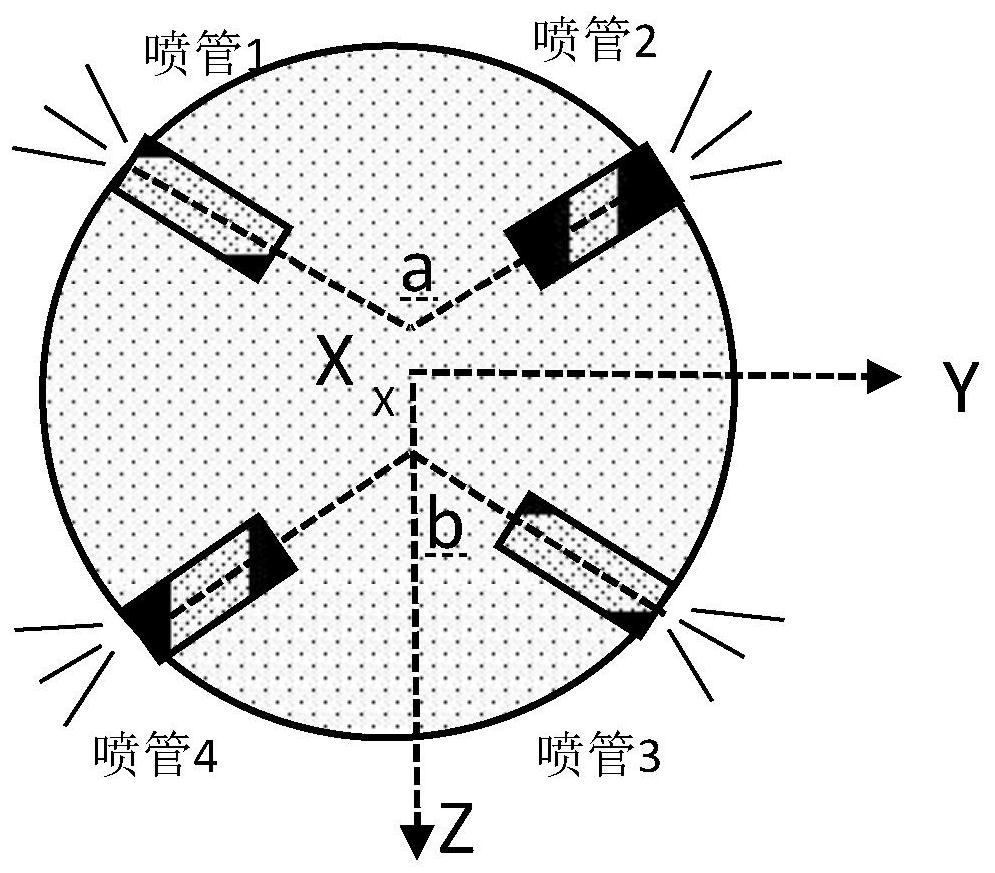

[0035] The structural principle of a tail seat type vertical take-off and landing UAV is as attached figure 1 As shown, it is mainly composed of the following main parts: fuselage 1, wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com