Mask automatic folding bagging equipment and operation method

A technology for bagging equipment and facial masks, which is applied in the fields of folding thin materials, packaging, and pharmaceutical formulas, which can solve the problems that facial masks cannot be folded in the middle, collapse, and cannot meet the needs of mass production, and achieve the effect of improving folding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

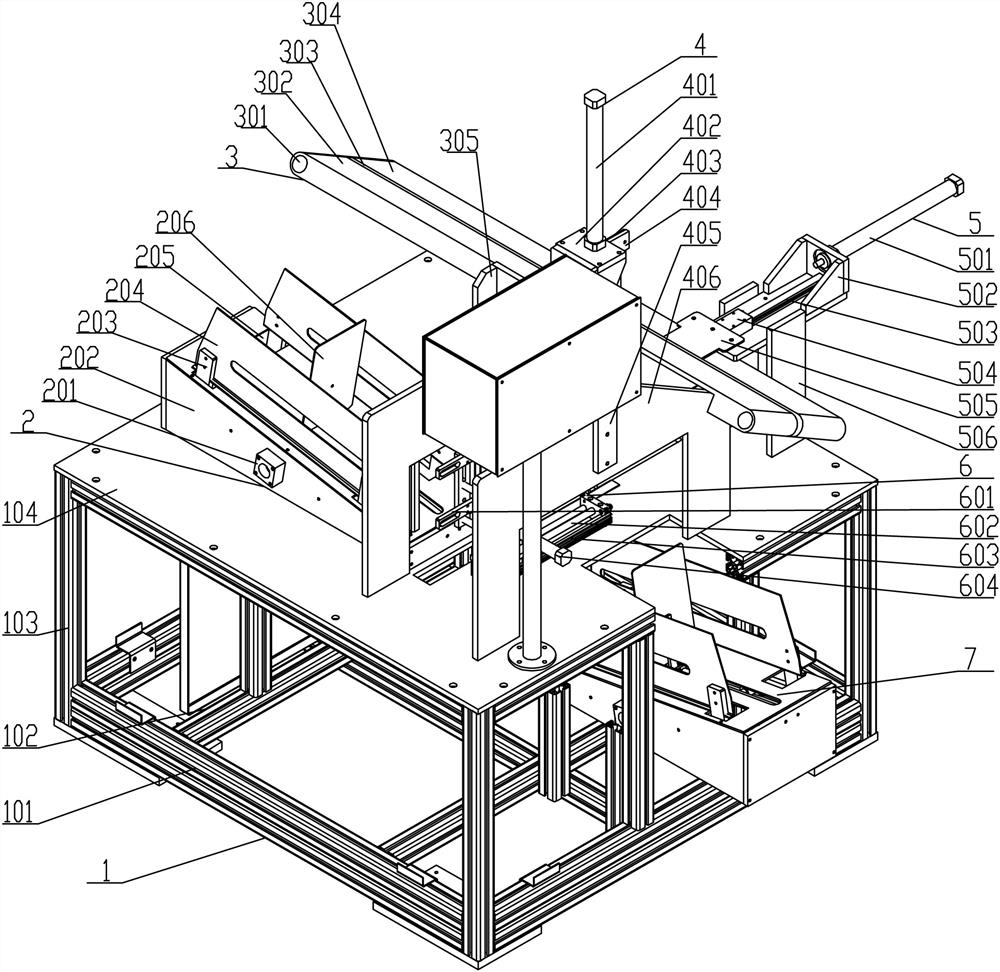

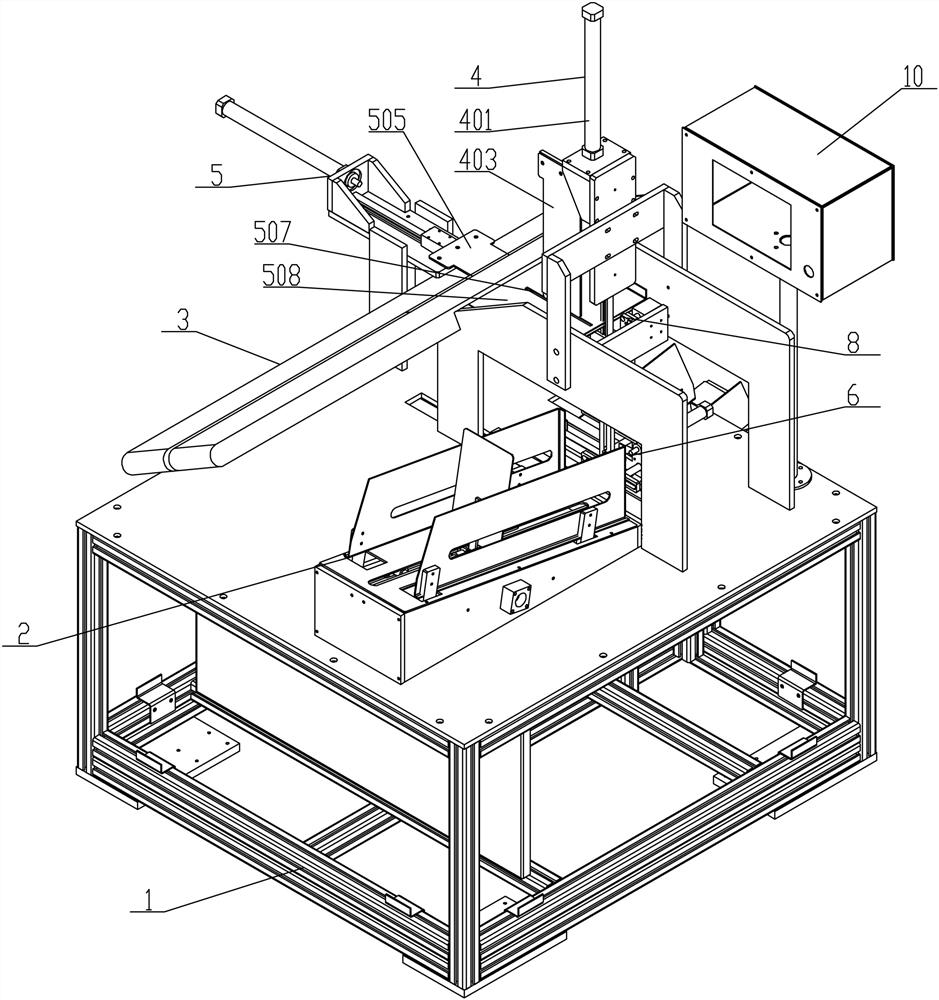

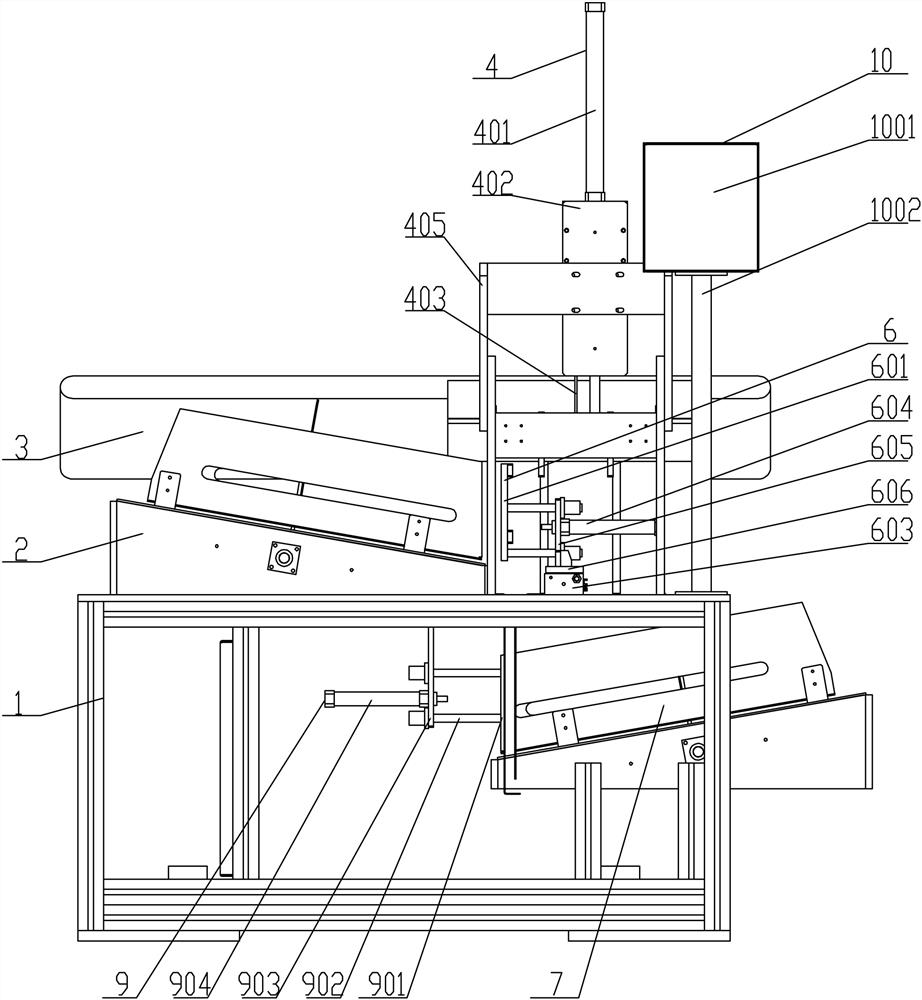

[0053] like Figure 1-6 , Mask automatic folding and bagging equipment, it includes a rack assembly 1, the top of the rack assembly 1 is installed with a feeding device 2 for automatic feeding of empty bags of packaging bags, and the position of the discharge port of the feeding device 2 A bag taking mechanism 6 for picking up packaging bags is installed, a conveying device 3 for feeding the mask is fixedly installed on the top of the frame assembly 1, and a horizontal folding mechanism 5 for one-fold folding of the mask is arranged along the direction of the conveying device 3 , the end of the horizontal folding structure 5 is provided with a vertical folding mechanism 4 for the secondary folding of the facial mask, and a bag opening mechanism 8 for opening the facial mask packaging bag is provided directly below the vertical folding mechanism 4. The bag mechanism 8 is arranged on the side of the end of the bag taking mechanism 6; the collecting device 7 for receiving the fac...

Embodiment 2

[0065] The operation method of any one of the described facial mask automatic folding bagging equipment is characterized in that comprising the following steps:

[0066] Step1: place the empty mask packaging bag used for packing the mask between the two baffle plates 204 of the feeding device 2, and use the pusher plate 206 to automatically press it all the time under the action of gravity;

[0067] Step2: Place the mask raw material one by one on the first conveyor belt 302 and the second conveyor belt 304 of the conveying device 3 by manual feeding;

[0068] Step3: When the mask reaches the position of the horizontal folding structure 5, start the horizontal folding cylinder 501, drive the horizontal folding plate 505 through the horizontal folding cylinder 501, fold the mask horizontally along its center and insert it through the interval slot 303 Level the feeder plate 508 and place it at the position where the slot 507 is located, and then complete the first folding;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com