Bag opening device of automatic vermicelli packaging machine

A technology of automatic packaging and machine opening of bags, which is applied in packaging and other directions, can solve problems such as increasing labor costs, affecting food safety, and secondary pollution of vermicelli.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

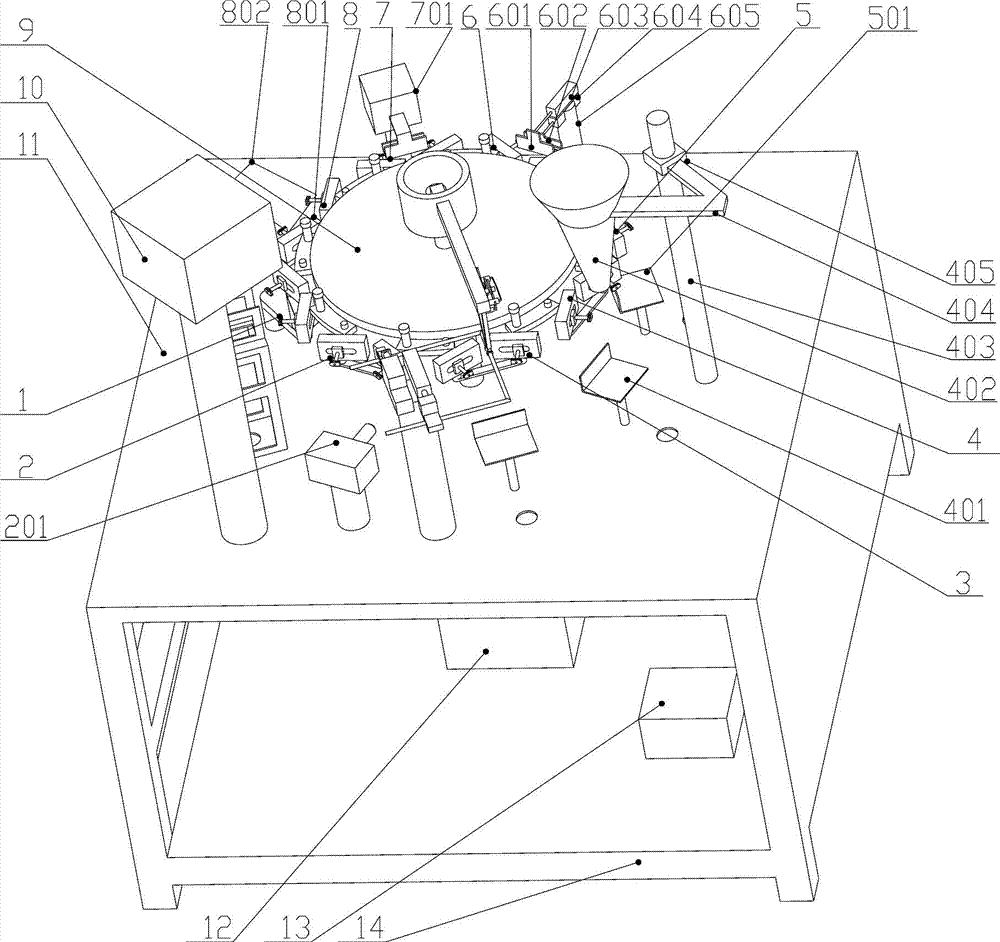

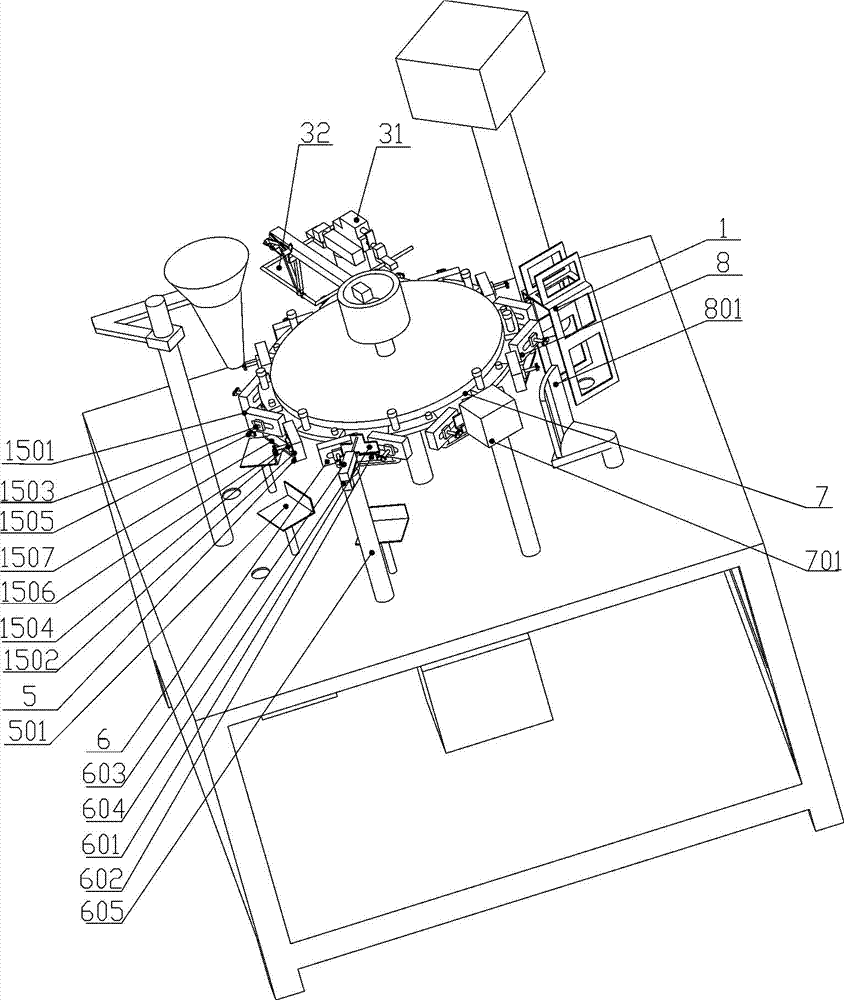

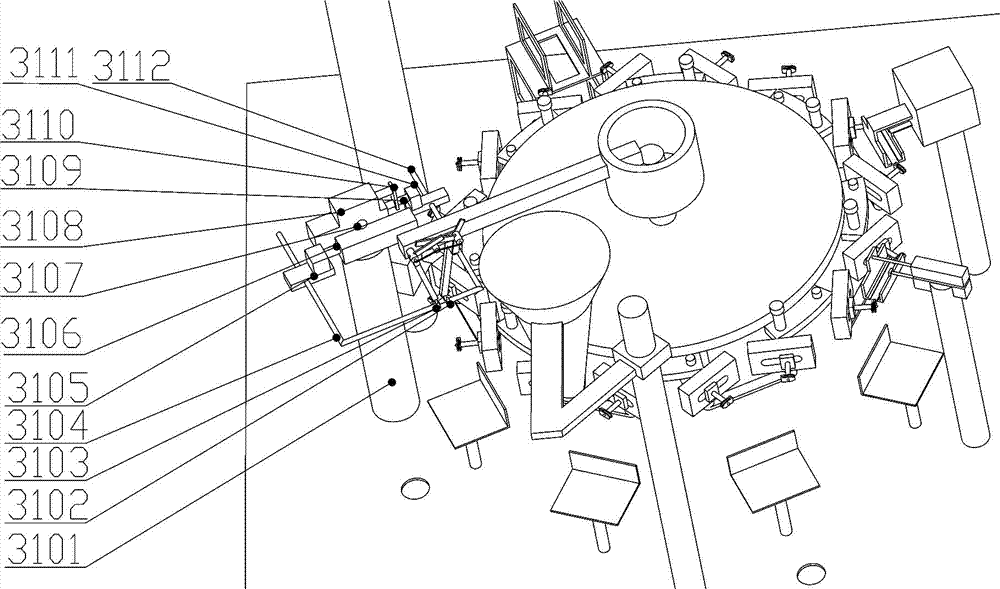

[0025] according to Figure 1-4 , the bag opening device of the vermicelli automatic packaging machine, comprising a frame 14, the workbench 11 is fixedly installed on the frame 14, the air compressor 13 and the cam divider 12 are installed on the bottom plate of the frame 14, and the output shaft of the cam divider 12 It is connected with the turntable 9, and the turntable 9 is provided with eight stations, and the touch screen 10 is arranged on the top of the workbench 11 through a bracket, and the feature is that the bag taking device 1 is installed on the workbench 11 and set at the first station, The coding device 2 is installed on the workbench 11 at the second station, the bag opening device 3 is installed on the workbench 11 at the third station, and the bagging device 4 is installed on the workbench 11 at the fourth station. The shaking device 5 is installed on the workbench 11 and is set at the fifth station, the trimming device 6 is installed on the workbench 11 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com