Vermicelli automatic packaging machine

An automatic packaging machine and vermicelli technology, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items. It can solve the problems that vermicelli can not achieve the smoothness and straightness of noodles, the noodle packaging machine cannot directly use vermicelli packaging, and increase the cost of employment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

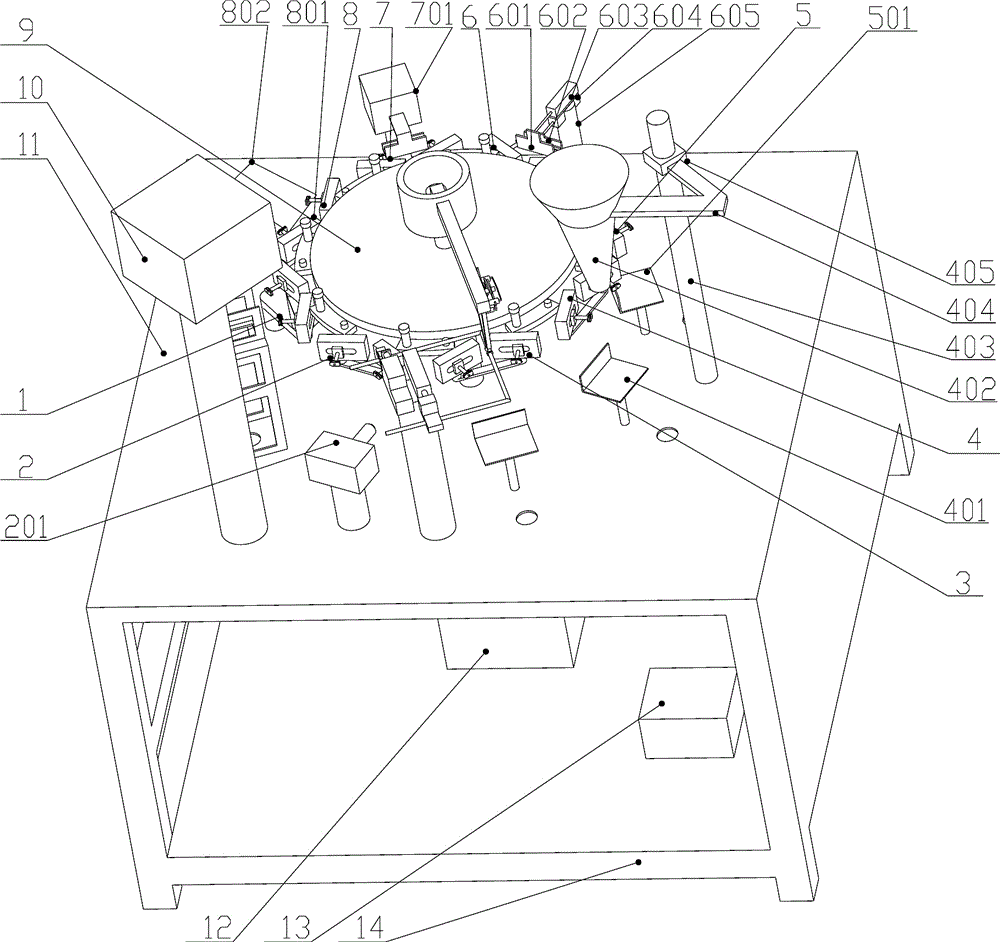

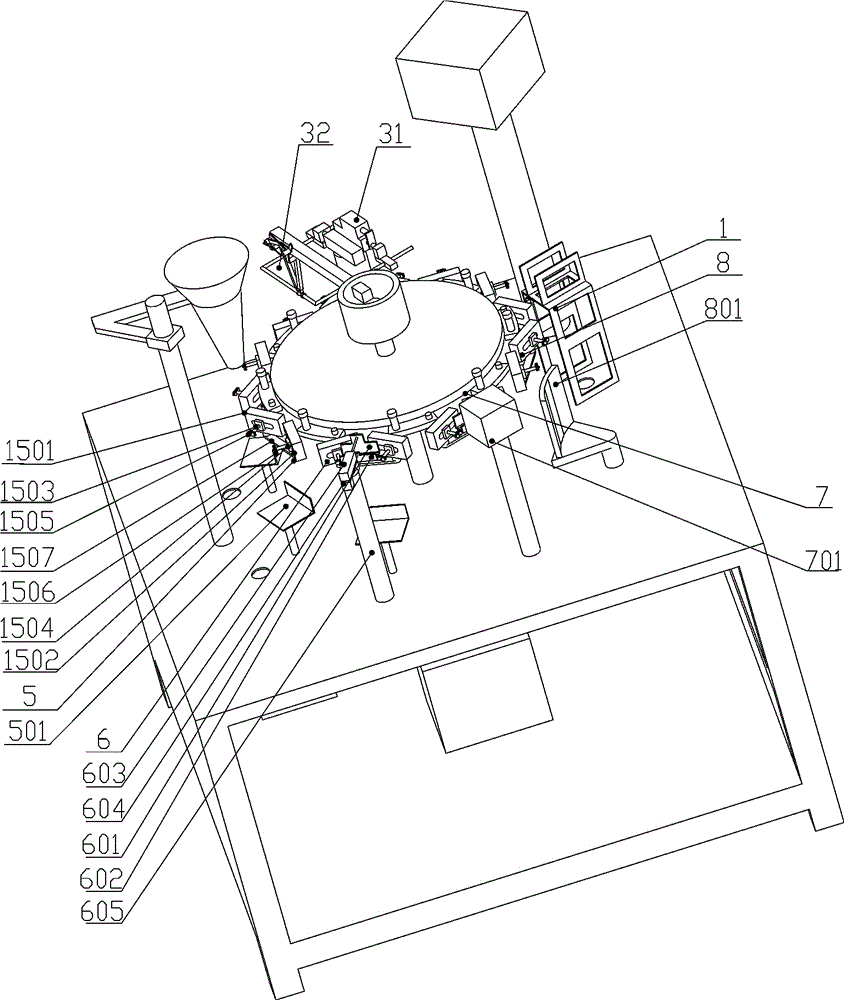

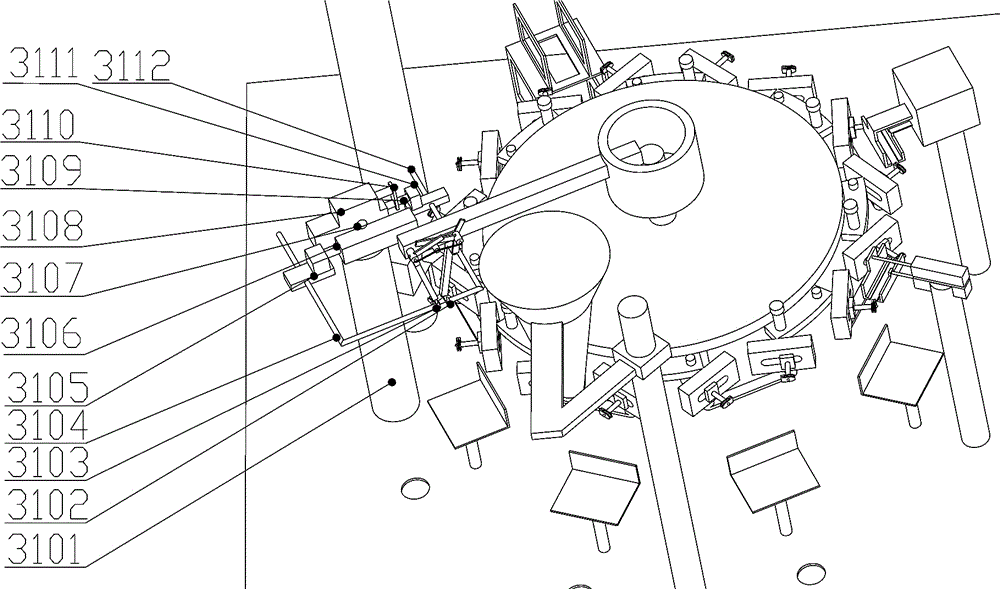

[0041] according to Figure 1-2, vermicelli automatic packing machine, comprises frame 14, and workbench 11 is fixedly installed on frame 14, and air compressor 13 and cam divider 12 are installed on the bottom plate of frame 14, and the output shaft of cam divider 12 and rotating disk 9 It is connected, and its feature is that there are multiple stations on the turntable 9, including the bag taking station, coding station, bag opening station, powder filling station, material shaking station, trimming station, and sealing station And the discharge station, the bag taking device 1 is arranged on the bag taking station on the workbench 11, the coding device 2 is arranged on the coding station on the workbench 11, and the bag opening device 3 is arranged on the opening on the workbench 11 The bagging station, the bagging device 4 is arranged on the powder loading station on the workbench 11, the shaker device 5 is arranged on the shaker station on the workbench 11, and the trimm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com