Internet-Based Hidden Projector

A hidden projector technology, applied in instruments, projection devices, optics, etc., can solve the problems of shortened service life of equipment, affecting the appearance of the office, inconvenient disassembly and maintenance, etc., to prevent dust accumulation, improve automation control rate, Effects that are easy to manipulate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] When lighting needs to be used, the indoor lighting work is realized through the ceiling lamp 844. When the ceiling lamp 844 works for a long time, the heat generated by the ceiling lamp 844 is absorbed by the heat sink 847, and then passed through the sixth bevel gear 852 on the joint control motor 851. Drive the fifth bevel gear 849 to rotate, and then the fourth pulley 850 on the fifth bevel gear 849 drives the first pulley 845 and the cooling blade 846 to rotate through the second belt 848, so that the heat on the cooling fin 847 passes through the cooling hole 843 Discharge, and then achieve rapid cooling work.

Embodiment 2

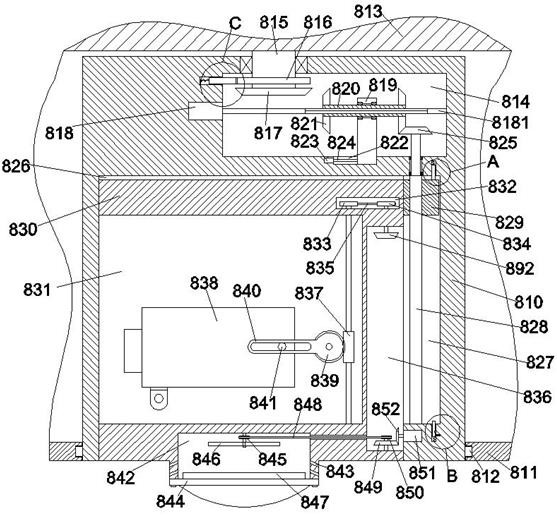

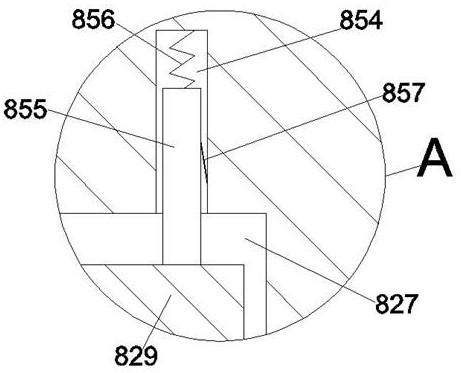

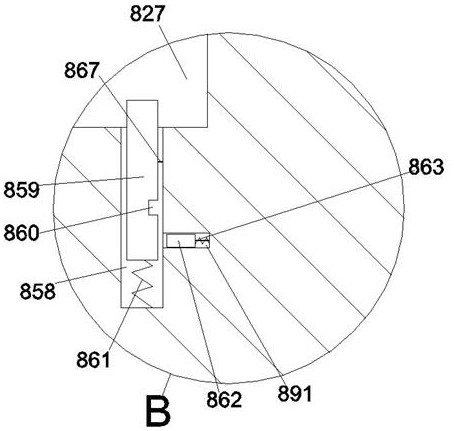

[0028] When projection work is required, the adjustment screw 824 is controlled by the adjustment motor 823 to rotate, so that the adjustment screw 824 drives the adjustment slider 819 to move to the rightmost position in the limit slip groove 822. At this time, the adjustment slider 819 drives the spline sleeve The second bevel gear 821 on the right side of the cylinder 820 is meshed with the third bevel gear 825. At the same time, the second bevel gear 821 on the left side of the spline sleeve 820 is kept away from the first bevel gear 817, and then the spline is driven by the driving motor 818. The rotating shaft 8181 rotates, and the splined sleeve 820 and the second bevel gear 821 are driven by the spline rotating shaft 8181 to rotate, and the second bevel gear 821 on the right side drives the third bevel gear 825 and the lifting screw 828 to rotate, so that the lifting screw 828 drives the guide The slide block 829 slides toward the bottom in the guide chute 827 until the...

Embodiment 3

[0030] When it needs to be packed up, the adjustment screw 824 is controlled by the adjustment motor 823 to rotate, so that the adjustment screw 824 drives the adjustment slider 819 to move to the rightmost position in the limit slip groove 822. At this time, the adjustment slider 819 drives the spline sleeve The second bevel gear 821 on the right side of the cylinder 820 is meshed with the third bevel gear 825. At the same time, the second bevel gear 821 on the left side of the spline sleeve 820 is kept away from the first bevel gear 817, and then the spline is driven by the driving motor 818. The rotating shaft 8181 rotates, the splined sleeve 820 and the second bevel gear 821 are driven by the spline rotating shaft 8181 to rotate, and the second bevel gear 821 on the right side drives the third bevel gear 825 and the lifting screw 828 to rotate in reverse, and then the lifting screw 828 drives the guide slider 829 to slide upwards, so that the top end of the guide slider 829...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com