Fluid chemical raw material rapid cooling device

A chemical raw material, rapid cooling technology, applied in cooling fluid circulation devices, household refrigeration devices, coolers, etc., can solve the problem of slow cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

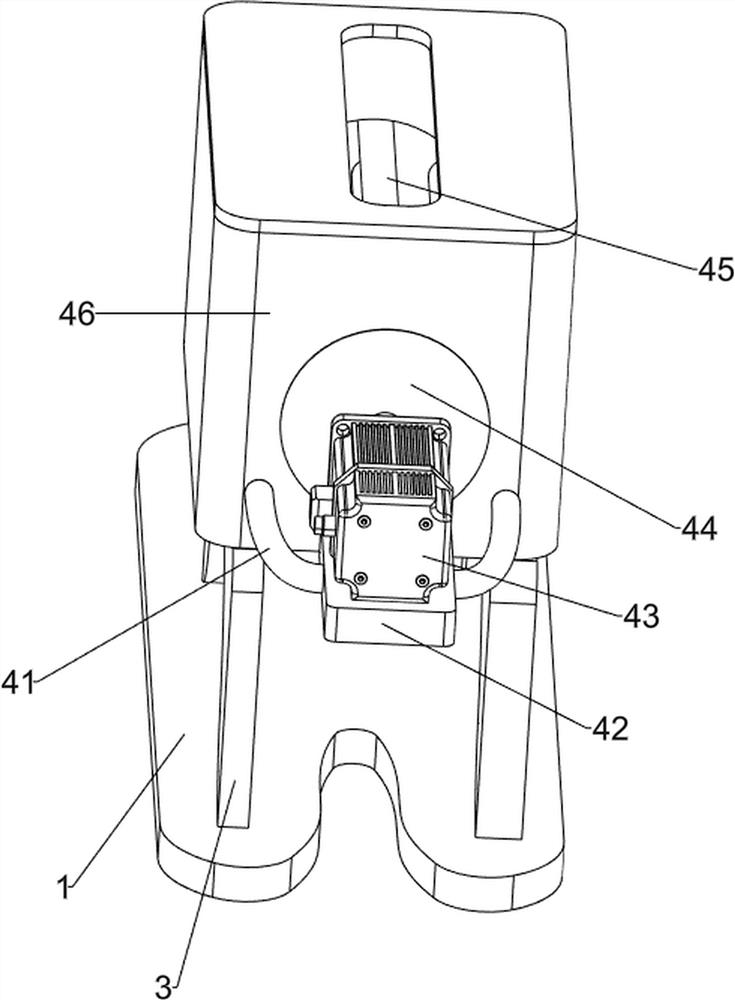

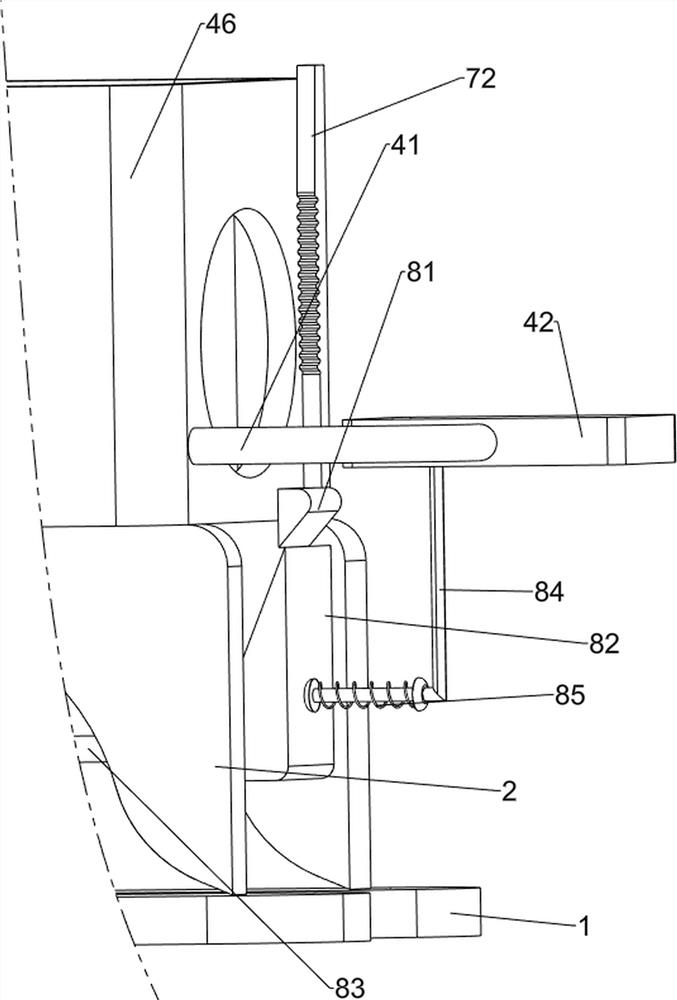

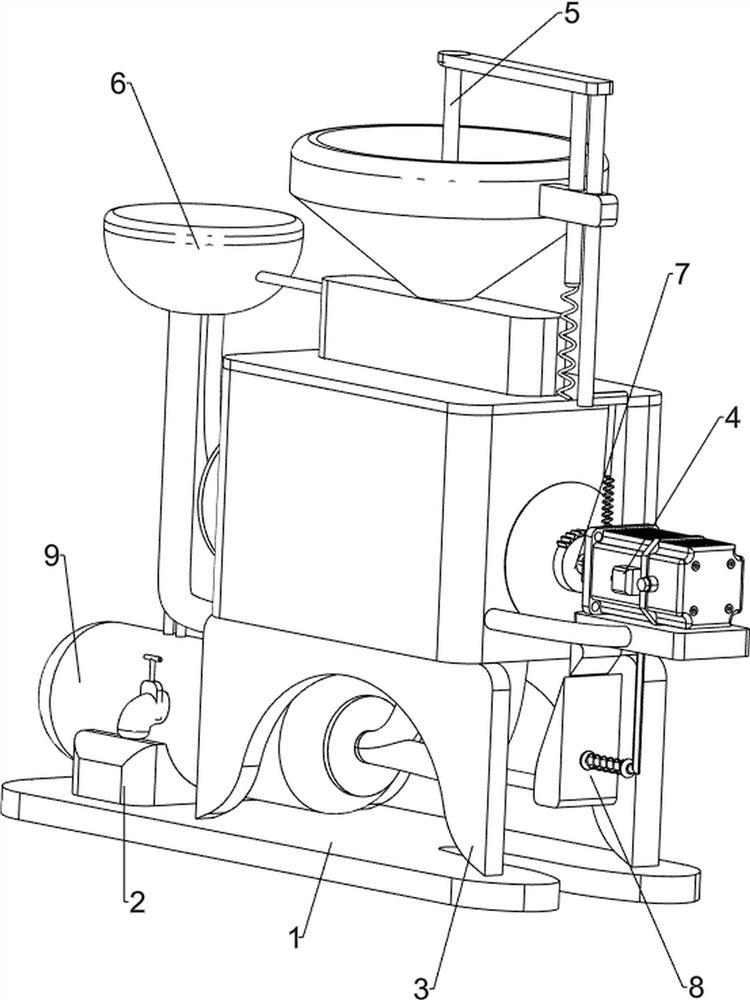

[0027] A rapid cooling device for fluid chemical raw materials, such as Figure 1 to Figure 3 As shown, it includes a base plate 1, a first support column 2, a second support column 3, a rolling mechanism 4 and a feeding mechanism 5. The left part of the base plate 1 is provided with the first support column 2, and the right part of the base plate 1 is provided with both front and rear sides. There is a second supporting column 3, a rolling mechanism 4 is arranged between the upper parts of the second supporting column 3, and a feeding mechanism 5 is arranged on the rolling mechanism 4.

[0028] When it is necessary to cool the fluid chemical raw materials, the fluid chemical raw materials are first poured into the feeding mechanism 5, and then the fluid chemical raw materials enter the rolling mechanism 4 through the feeding mechanism 5, and the fluid chemical raw materials are cooled by the rolling mechanism 4. The auxiliary cooling of the raw materials is carried out. After...

Embodiment 2

[0034] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, a refrigeration mechanism 6 is also included. The refrigeration mechanism 6 includes a condenser 61, a first condensation pipe 62, a second condensation pipe 63, a third condensation pipe 64, a second connecting rod 65 and a second condensation box 66. The left part of a condenser box 51 is connected with a first condenser pipe 62, the left part of the first condenser pipe 62 is connected with a condenser 61, the bottom of the condenser 61 is connected with a second condenser pipe 63, and the bottom of the condenser 61 is connected with a third condenser pipe 64 A second connecting rod 65 is connected to the lower part of the second condensation pipe 63 , and a second condensation box 66 is connected to the right side of the second connecting rod 65 in a rotational manner, and the second condensation box 66 is connected to the rotating column 45 .

[0035] After po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com