Manufacturing equipment of high steel grade thick wall petroleum casing pipe diameter variable joints

A technology of oil casing and variable diameter joints, which is applied in the direction of non-rotational vibration suppression, coil springs, household components, etc., can solve the problems of slow mold cooling speed, limitation of extruding slender pipe fittings, and affecting the molding effect, so as to improve production Efficiency and quality, and the effect of improving the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

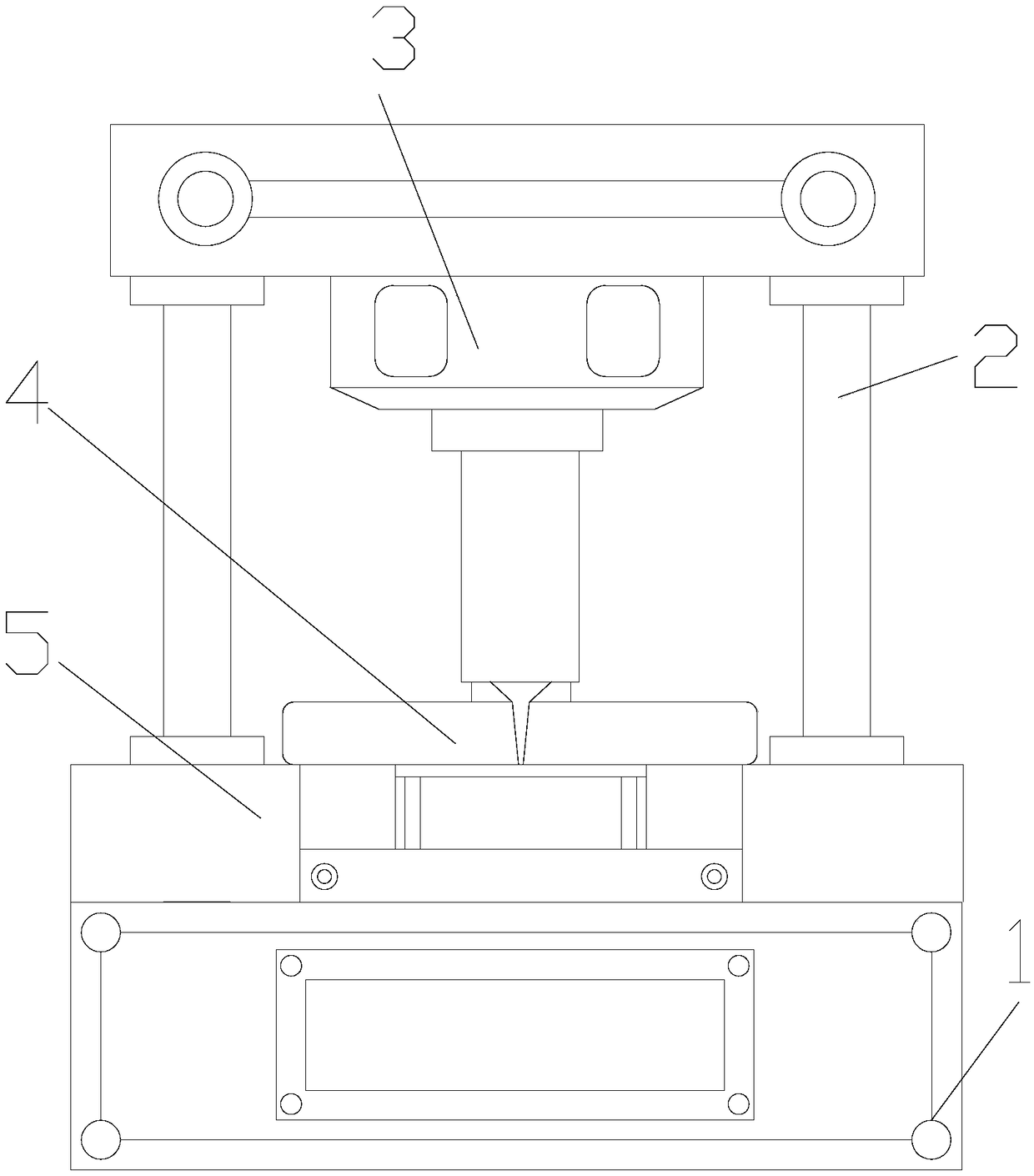

[0024] see Figure 1-Figure 5 , the present invention provides high-grade thick-wall oil casing reducing joint manufacturing equipment, the structure of which includes a fixed base 1, a body support frame 2, a hydraulic device 3, a mold 4, and a rapid cooling device 5, and the rapid cooling device 5 passes through It is installed on the left and right ends of the top surface of the fixed base 1 in an embedded manner. The mold 4 is arranged directly below the hydraulic device 3. The head end of the hydraulic device 3 and the end of the body support frame 2 are welded together by electric welding. The end of the body support frame 2 is vertically connected to the fixed base 1 through a rapid cooling device 5, and is characterized in that:

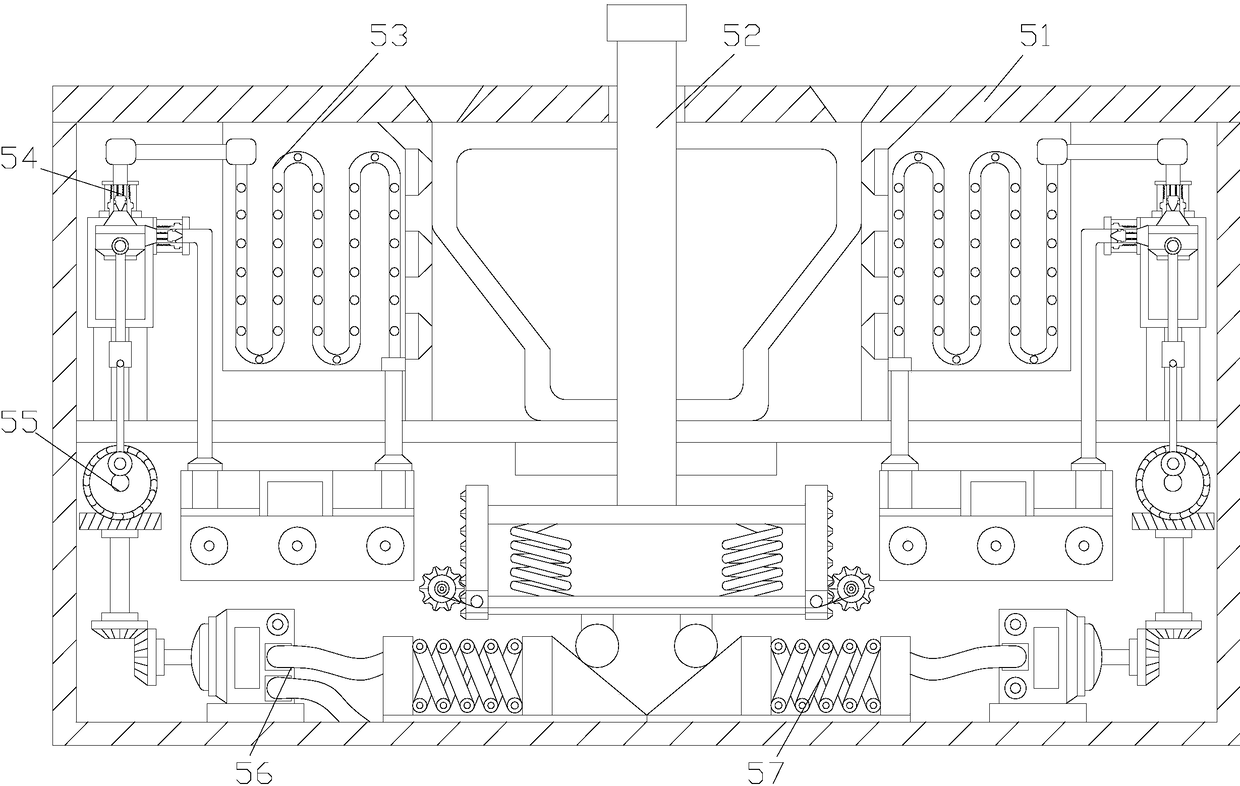

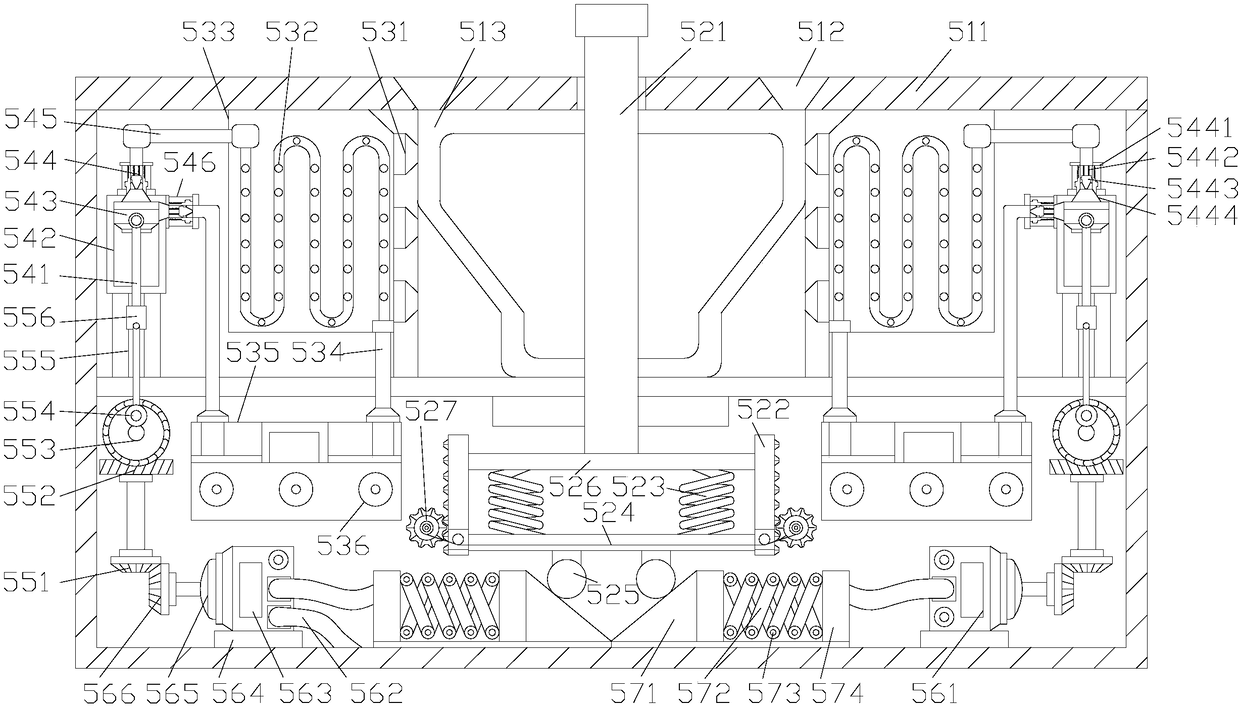

[0025]Described rapid cooling device 5 comprises injection mold casing 51, guide mechanism 52, rapid cooling mechanism 53, piston movement mechanism 54, power transmission mechanism 55, power motor mechanism 56, shock-absorbing buffer mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com