Filler-saving two-stage gas treatment device

A processing device, gas technology, applied in the field of gas fixed bed processing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

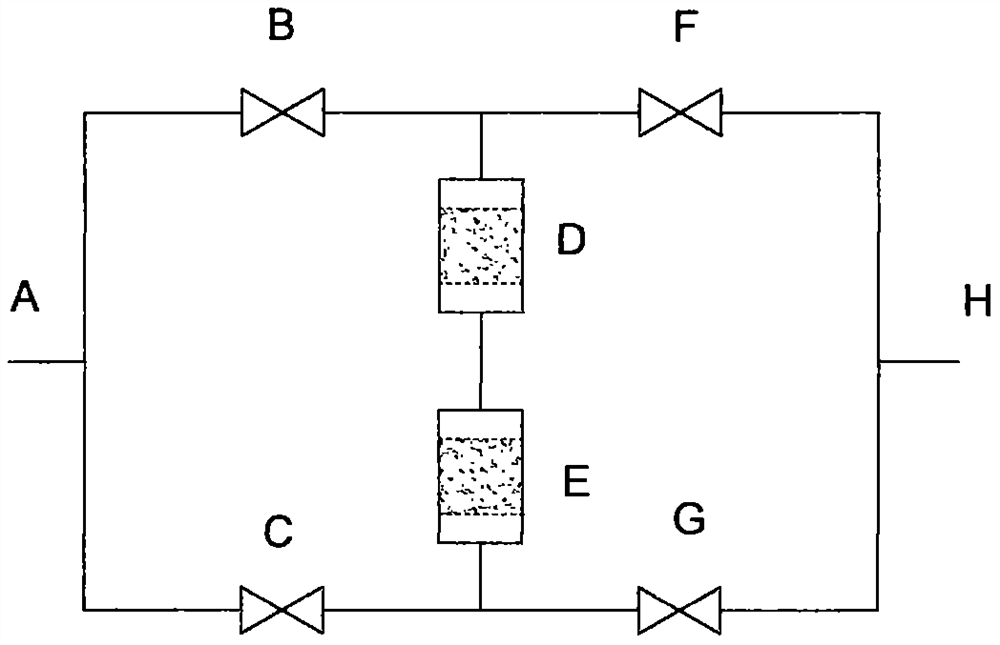

[0014] Example 1 Two-stage adsorption device with independent adsorption unit

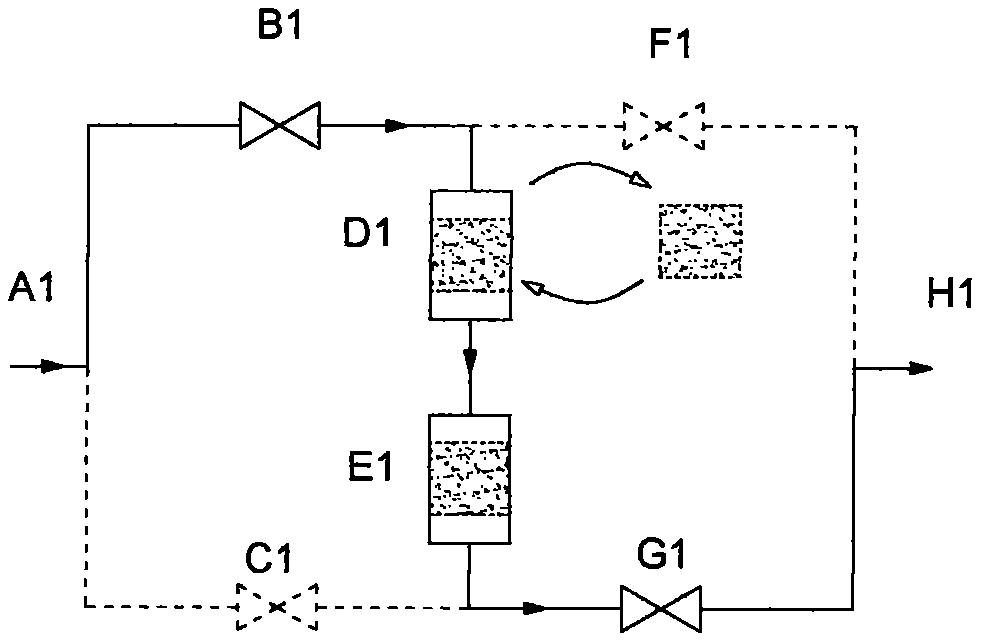

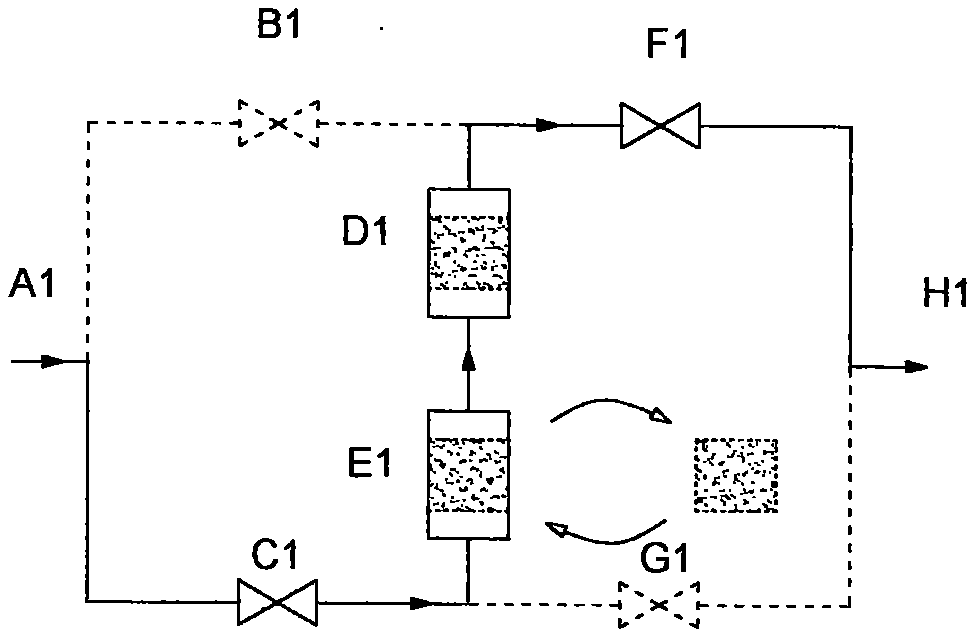

[0015] See attached Figure 2-3 . The device includes intake manifold A1, intake switching valve B1, intake switching valve C1, adsorption unit D1, adsorption unit E1, exhaust switching valve F1, exhaust switching valve G1 and exhaust manifold H1. The adsorption units D1 and 1E are equivalent to two independent fixed-bed adsorbers.

[0016] When the device works, it first works in the way 1) A1-B1-D1-E1-G1-H1, and the adsorbent in the adsorption unit D1 reaches saturation first, and the adsorption unit E1 has not penetrated yet. Replace the adsorbent in the adsorption unit D1, switch the gas passage to the mode 2) A1-C1-E1-D1-F1-H1, until the adsorbent in the adsorption unit E1 reaches saturation, then replace the adsorbent in the adsorption unit E1 , and switch the gas passage to mode 1), and so on.

Embodiment 2

[0017] Example 2 Compact matrix two-stage adsorption device

[0018] The adsorption units D1 and E1 in Example 1 are replaced by multiple parallel fixed beds I and J, and the gas pipeline connected between the two adsorption units is replaced by a grid plate K that divides the two adsorption sections. The gas sequence runs through the parallel fixed beds of the attached units D and E, and the valves B1, C1, E1, and F1 are set as two sets of linked switching valves L and M, and the adsorption device is transformed into a more practical compact matrix two-stage level adsorption device. The side-by-side fixed beds can be set as adsorbent drawers for easy replacement, which can further simplify the operation process of replacing the adsorbent. This knot structure can also greatly reduce the wind resistance of the device.

Embodiment 3

[0019] Example 3 Combination of compact matrix two-stage adsorption device and pre- and post-treatment processes

[0020] When the compact matrix two-stage adsorption device is used for VOCs gas removal and combined with pre- and post-processing devices such as dust filter N, and post-processing devices such as hydrogen sulfide catalytic oxidizer O, the advantages of compact device structure can be more reflected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com