A Realization Method of Strapdown Inertial Group Calibration System Based on Labview

An implementation method and a technology for calibrating system, which are applied in the field of strapdown inertial group calibration system, can solve the problems of long cycle of automatic calibration software, increase the difficulty of program writing, cumbersome program code, etc., so as to save manpower and time, have powerful functions and develop simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

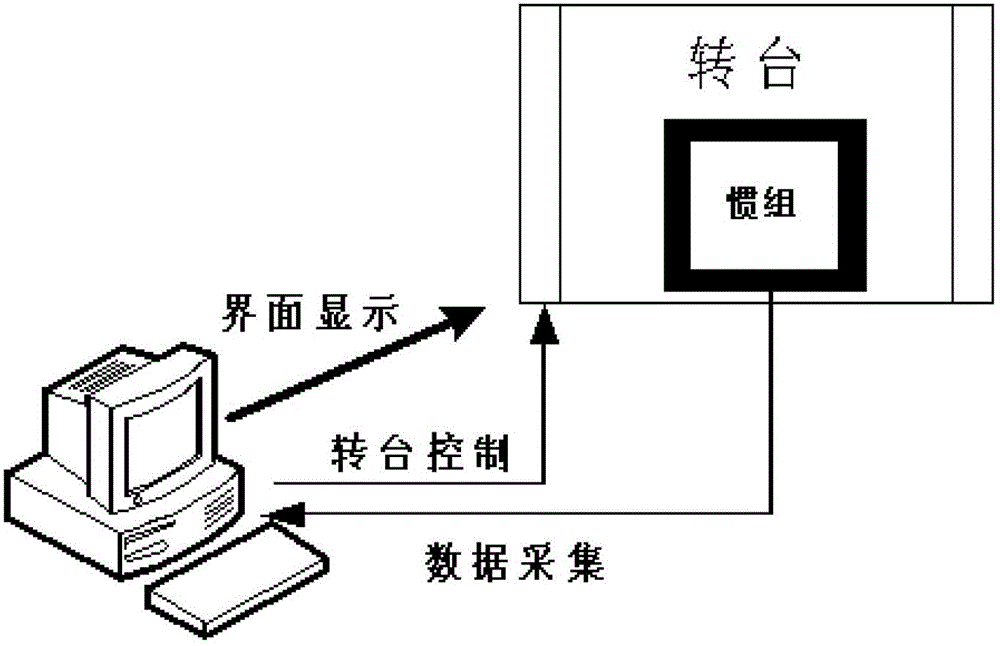

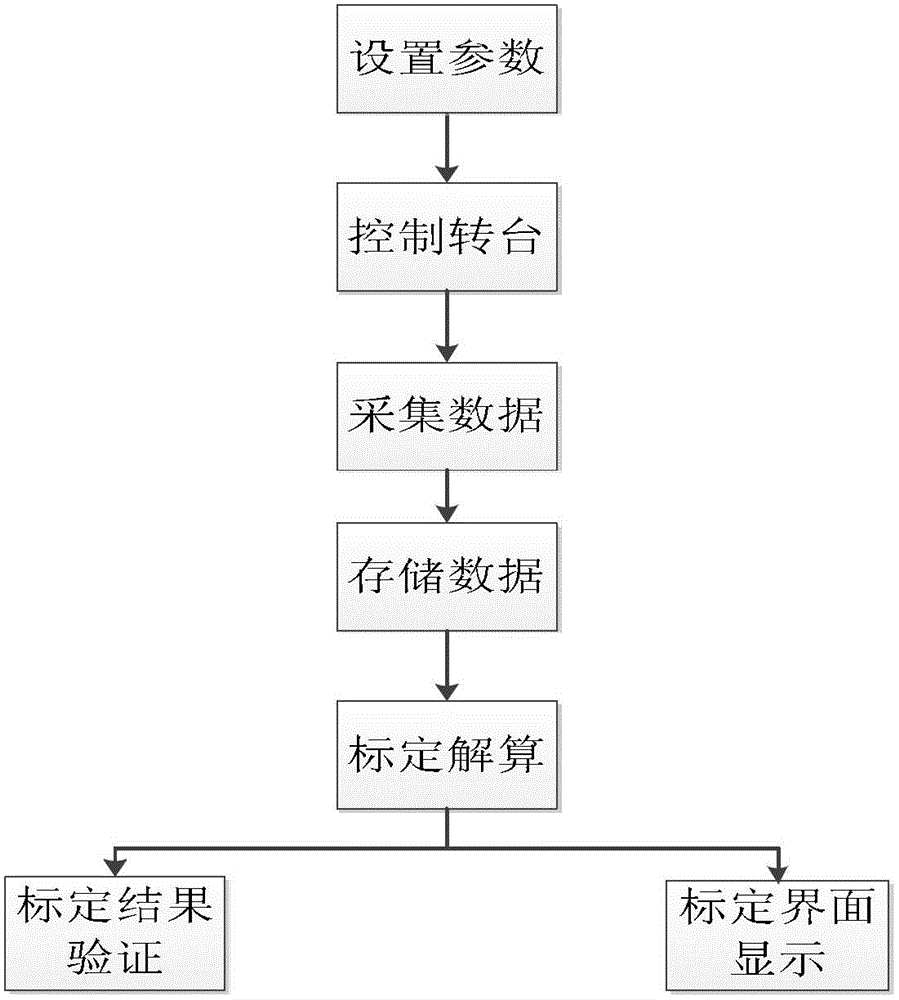

[0038] This embodiment provides a method for implementing a Labview-based strapdown inertial group calibration system, such as figure 1 As shown, the system mainly includes the upper computer, Labview automatic calibration software and turntable, which involves setting parameters, controlling the turntable, collecting data, storing data, calibration calculation, calibration result verification, calibration interface display and functions. The process is as follows figure 2 shown.

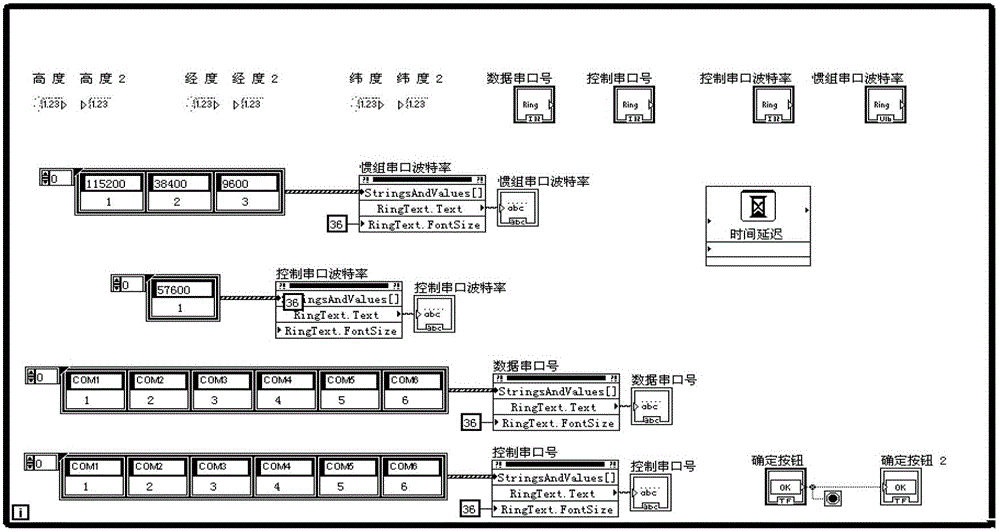

[0039] Step 1: Set parameters

[0040] This step is mainly used to set the correct serial port number and the corresponding serial port baud rate according to the characteristics of the calibration object and the turntable used in calibration and the interface used when connecting to the host computer; at the same time, it can be input in this module Calibrate the latitude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com