Rice bagging machine

A bagging machine, rice technology, applied in the directions of packaging, transportation and packaging, the type of packaged items, etc., can solve problems such as arm soreness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

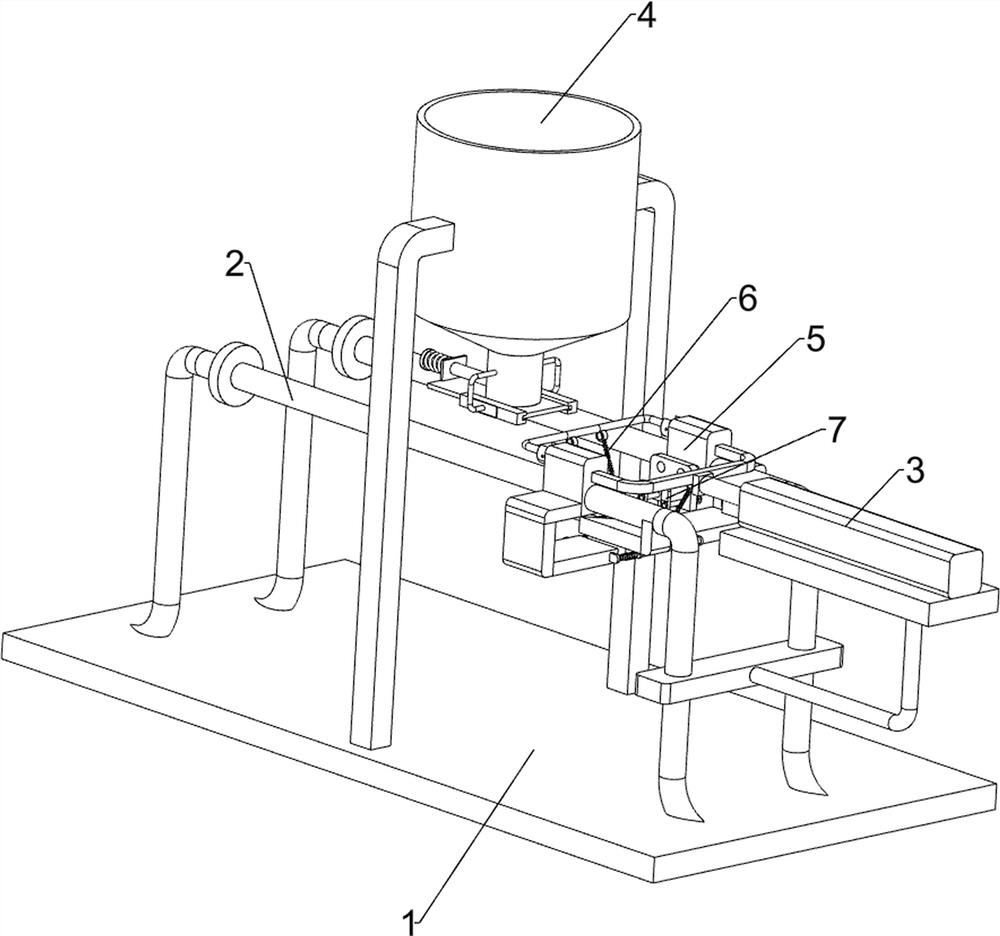

[0070] A rice bagging machine, such as figure 1 As shown, it includes a frame 1, a guide device 2, a cylinder 3, a feeding device 4, a moving device 5 and a gravity device 6, a guide device 2 is provided in the middle of the top of the frame 1, and a cylinder 3 is provided on the top of the right side of the guide device 2. , The guide device 2 is slidingly provided with a mobile device 5, the mobile device 5 is connected with the cylinder 3, the mobile device 5 is provided with a gravity device 6, and the middle of the frame 1 top is provided with a blanking device 4.

[0071]People can use the present invention to fill the bag with rice. First, people place the empty bag on the gravity device 6, then people compress the air cylinder 3, and the telescopic rod of the air cylinder 3 moves to the left, which will push the moving device 5 to move to the left, and then drive the gravity device. 6 moves to the left, and the moving device 5 will be in contact with the unloading devi...

Embodiment 2

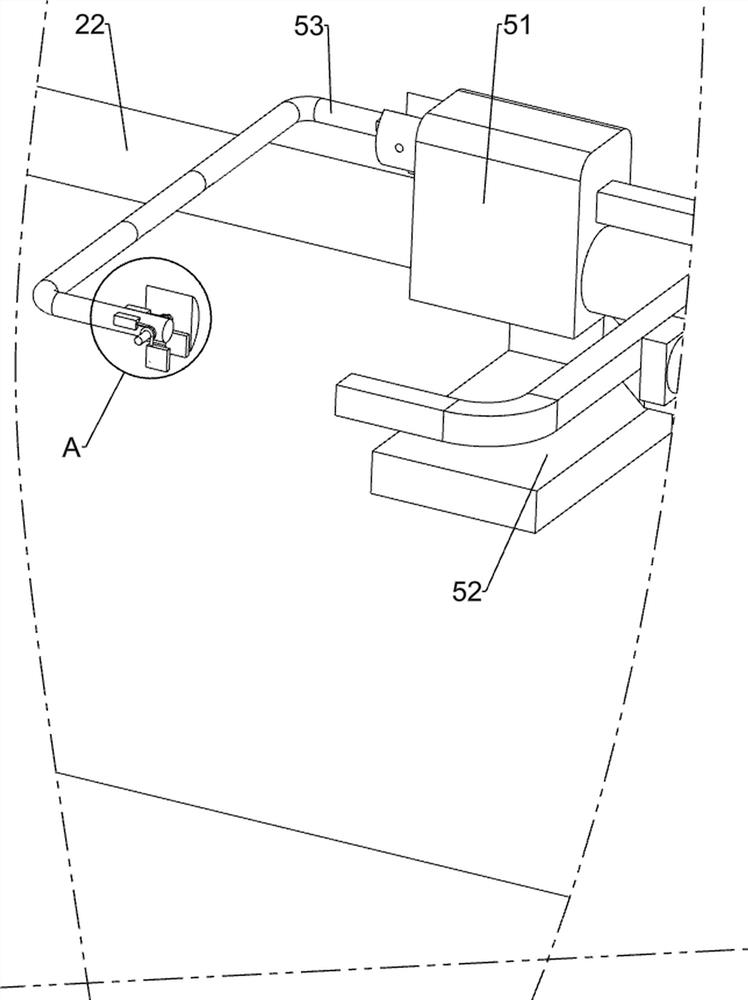

[0073] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, the guiding device 2 includes a tripod 21, a first guide rod 22, a first restricting block 23, a connecting block 24, a wedge block 26 and an L-shaped connecting rod 25, and the front and rear sides of the top of the frame 1 are symmetrically arranged. There are four tripods 21, the first guide rods 22 are arranged between the tripods 21 on the left and right sides, the left sides of the two first guide rods 22 are provided with first limiting blocks 23, and the front and rear two tripods on the right side A connection block 24 is connected between the middle parts of 21, an L-shaped connecting rod 25 is provided on the right side of the connection block 24, and a wedge-shaped block 26 is provided at the right bottom of the two first guide rods 22.

[0074] The guide device 2 is used to support the cylinder 3, the moving device 5 and the gravity device 6. When the operator com...

Embodiment 3

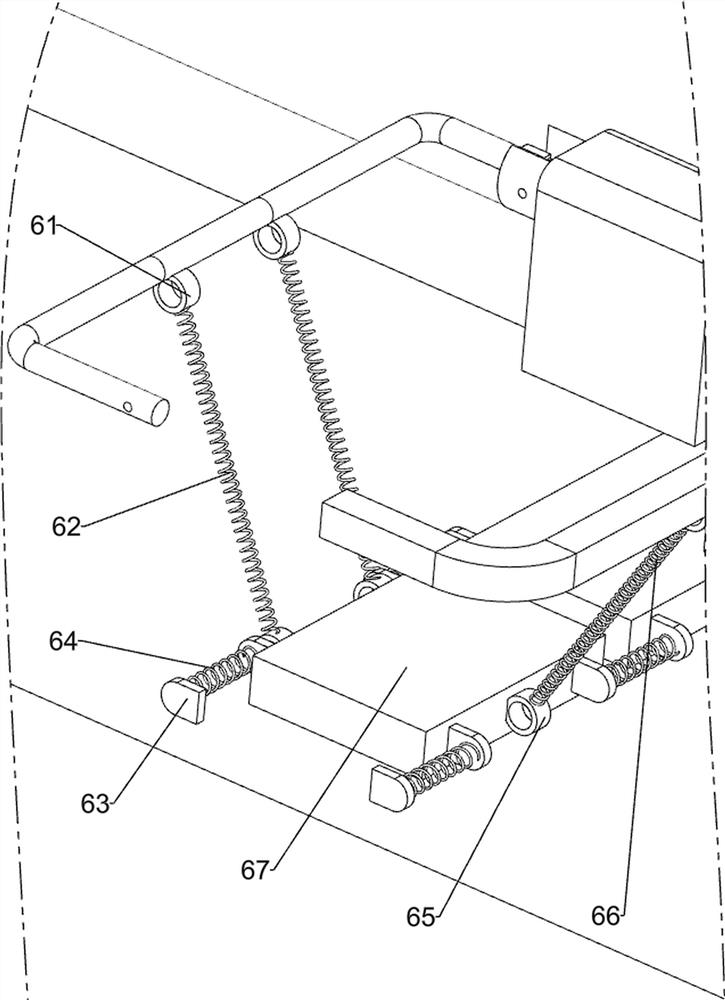

[0082] On the basis of Example 2, such as Figure 6 and Figure 7 Shown, also includes limiting device 7, and limiting device 7 comprises second connecting rod 71, support plate 72, the 3rd connecting rod 73, connecting plate 74, the 5th spring 75, the 4th fixed plate 76, rotating plate 77, The fifth fixed plate 78, the post 710 and the second torsion spring 79, two second connecting rods 71 are arranged on the lower parts of the front and rear sides of the slide block 51, and a support plate 72 is arranged between the left and right second connecting rods 71 to support Plate 72 bottom, left and right sides all sliding type is provided with the 3rd connecting rod 73, and all rotating type is provided with post 710 on the 3rd connecting rod 73, is provided with connecting plate 74 between the 3rd connecting rod 73 of left and right sides, connecting plate 74 and the support plate 72 are connected with a fifth spring 75, the fifth spring 75 is sleeved on the third connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com