Packing device for annular steel bars

A technology of ring-shaped steel bars and pressure devices, which is applied in the direction of packaging and binding machine parts, etc., can solve problems such as insufficient efficiency, and achieve the effect of improving efficiency and solving insufficient efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

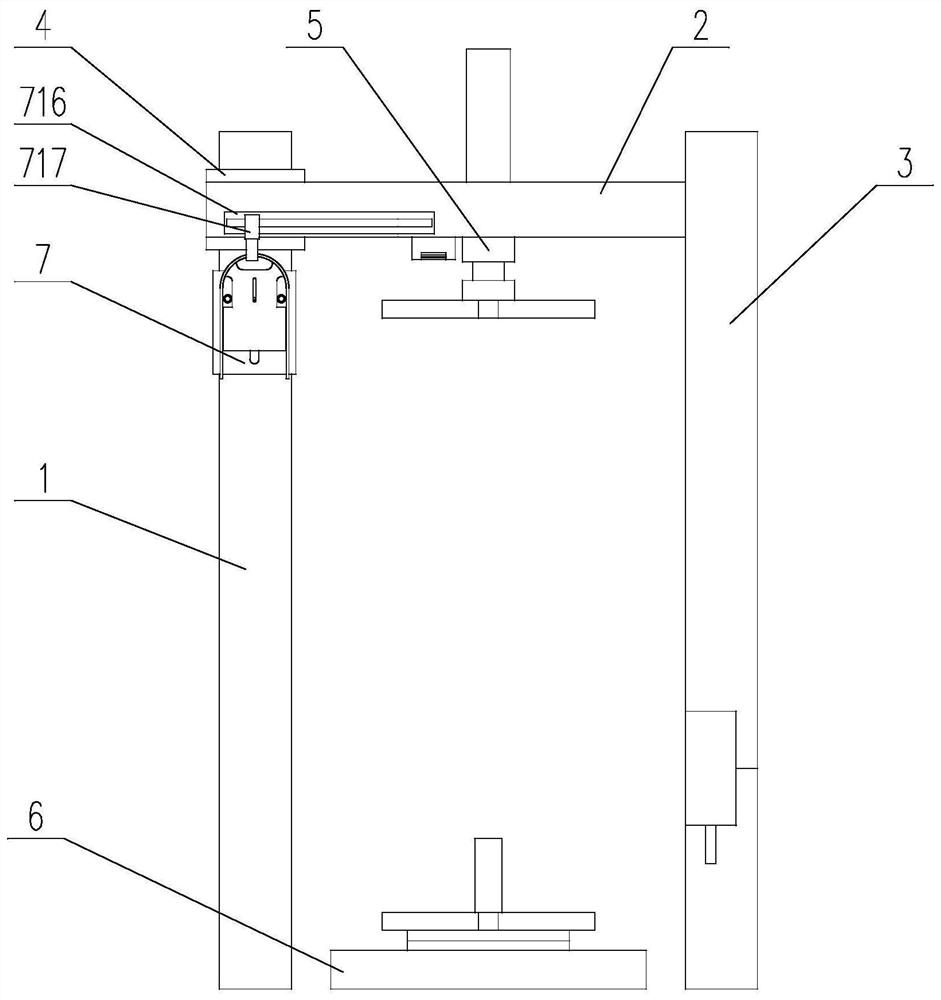

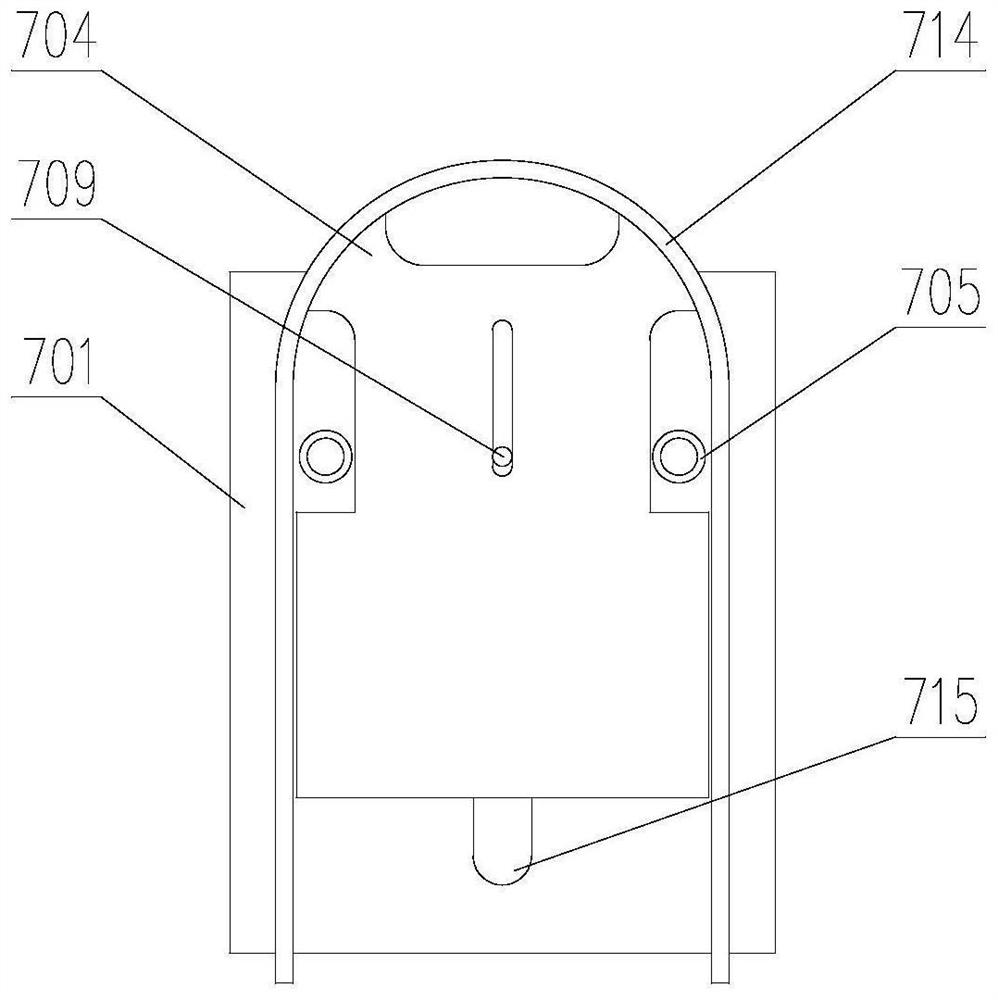

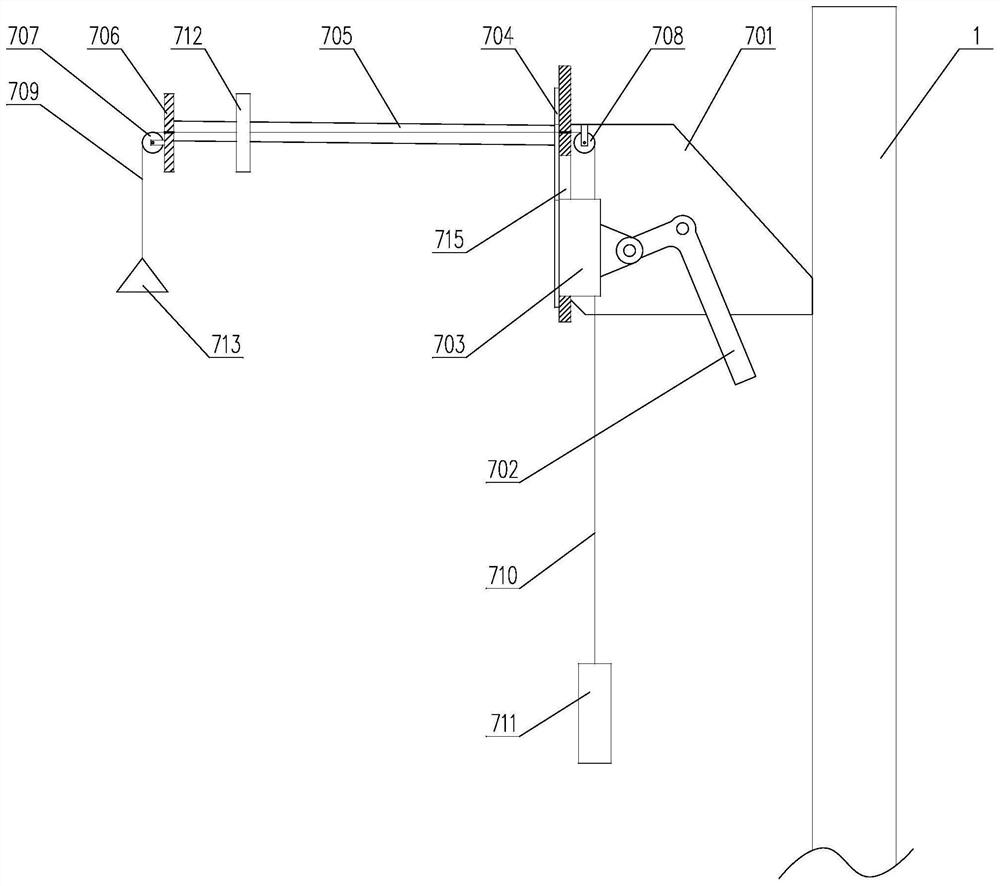

[0039] A packaging device for circular steel bars, comprising a gantry device and a placing device 7, the gantry device includes a gantry body, a fixing device 6 and a pressure device 5, and the gantry body includes a first column 1 and a beam 2 And the second column 3, the top of the first column 1 is connected with one end of the beam through the rotating device 4, the other end of the beam 2 is connected with the top of the second column 3, the fixing device 6 is installed on the ground, And located between the first column 1 and the second column 3, the pressure device 5 is connected to the bottom surface of the beam 2;

[0040] The second column 3 includes a connecting column 302 and a fixed column 301, the connecting column 302 is connected with the fixed column 301 installed on the ground through a connecting assembly, and the connecting assembly includes a fixed plate 303, a connecting plate 305, and a movable plate 304 , limiting plate 306, movable block 307, mating b...

Embodiment 2

[0046] A specific implementation description is made for the operation mode in Embodiment 1.

[0047] like Figure 5 As shown, in the present invention, a push rod 317 is connected to the side of the movable block 307 away from the fixed post 301. The push rod 317 is a better point of application of force, and the user can better push the movable block 307 by the push rod 317. The surface of the rod 317 is provided with anti-skid lines, which can increase the frictional force and prevent hands from being released when the push rod 317 is gripped tightly to apply force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com