Self-adaptive transport case for logistics storage based on engineering manufacturing

An adaptive, transport box technology, applied in the direction of transportation and packaging, removable cover/cover, cover with auxiliary devices, etc., can solve problems such as difficult recycling, waste of resources, damage to boxes and goods, etc. , to achieve a good fixing effect, easy to use next time, and realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

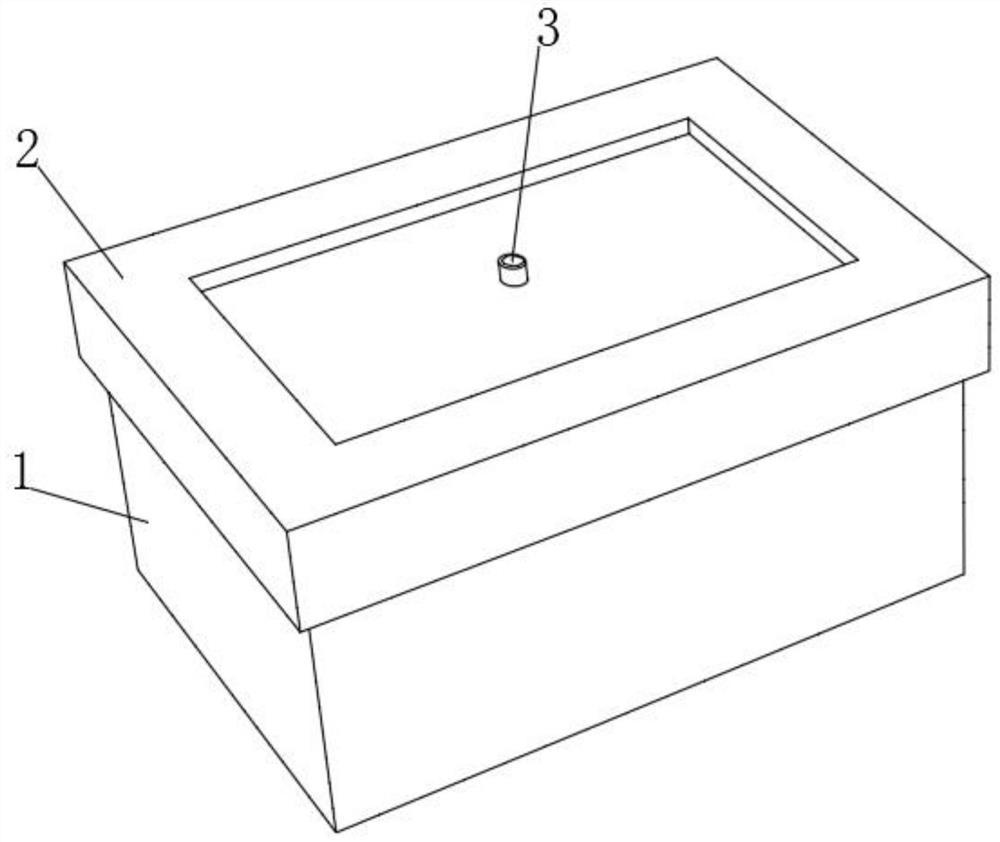

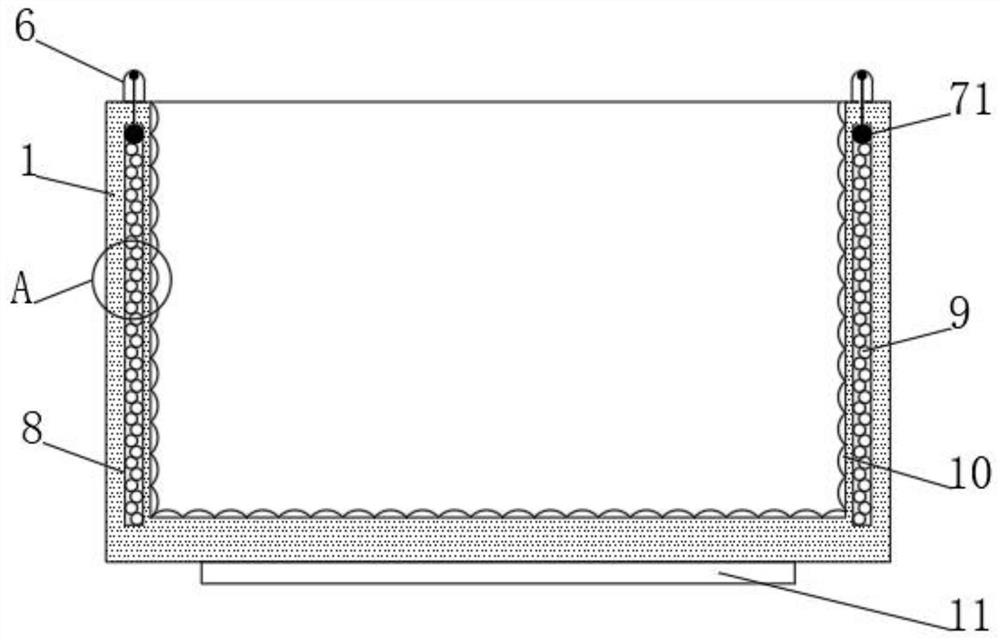

[0040] see figure 1 , an adaptive transportation box for logistics and storage based on engineering manufacturing, including a box body 1 , and a double air bag cover 2 is provided on the upper end cover of the box body 1 .

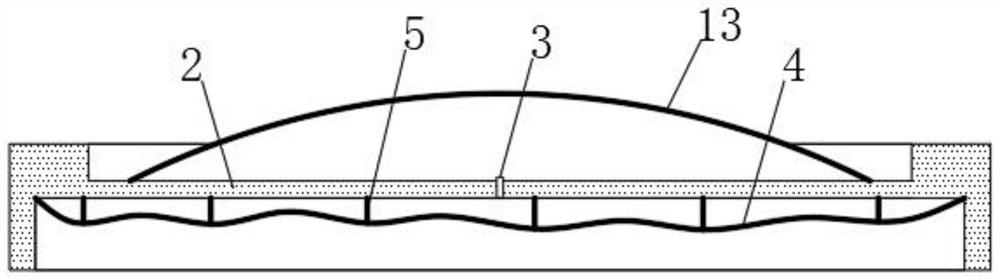

[0041] see figure 2 , the inner top of the double airbag cover 2 is fixedly connected with the inner limit airbag 4, the middle part of the double airbag cover 2 is fixedly connected with the air pipe 3, the upper end of the double airbag cover 2 is fixedly connected with the external air storage drum 13, and the air pipe 3 is connected with the external air storage The drum 13 and the inner spacer air bag 4, and the outer gas storage drum 13 and the inner spacer air bag 4 are filled with inert gas, and the outer gas storage drum 13 and the inner spacer air bag 4 are all made of elastic sealing materials, and Both the outer surface of the outer air storage drum 13 and the inner limit air bag 4 are coated with LINE-X paint coating, which can effectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com