Carrying clamp and stacking equipment

A fixture and handling box technology, which is applied in the stacking of objects, unstacking of objects, transportation and packaging, etc., can solve the problem that the fixture cannot be applied to various types of box-type products, achieve compact structure, and improve stacking efficiency , the effect of increasing the load range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

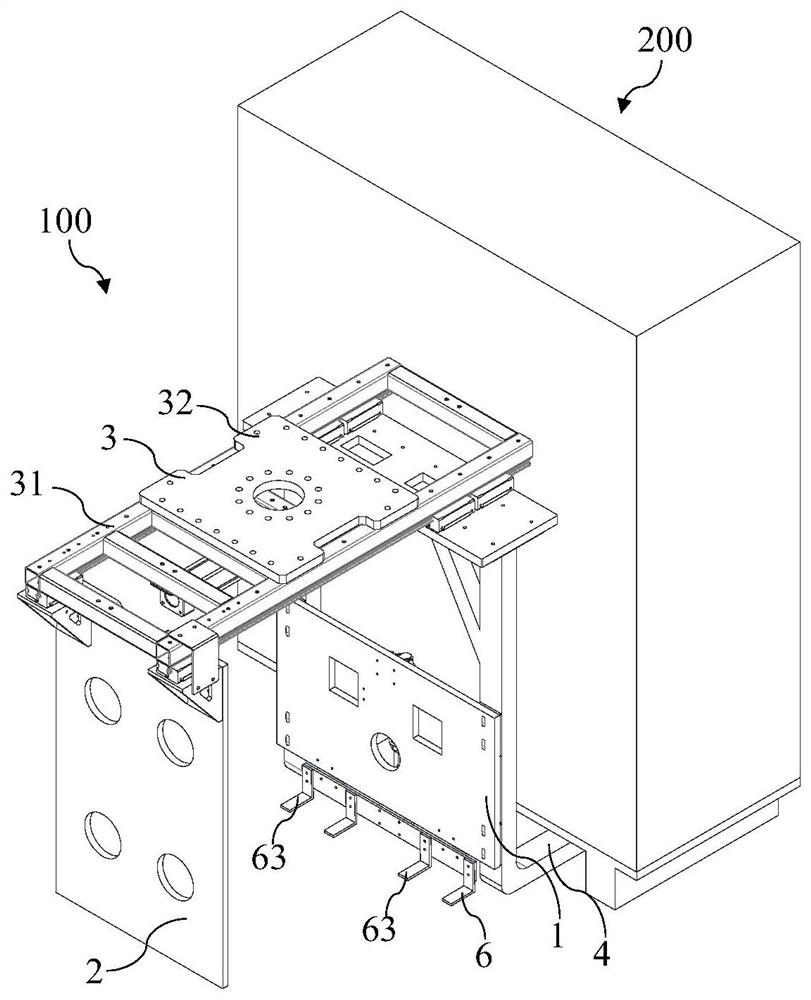

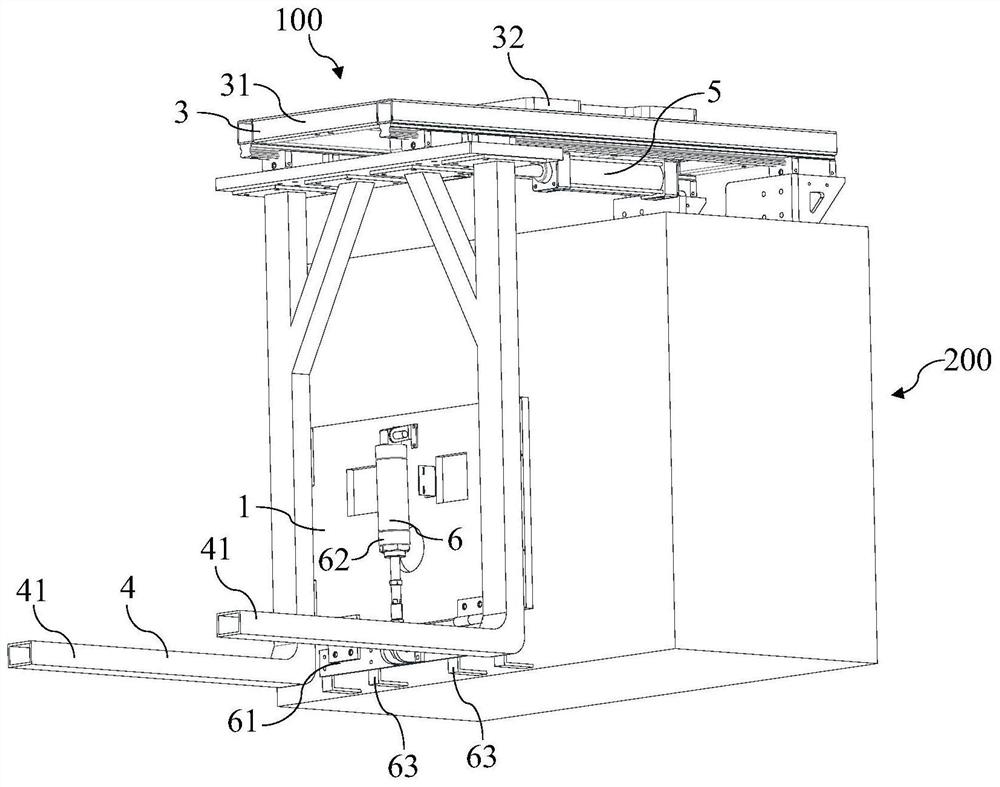

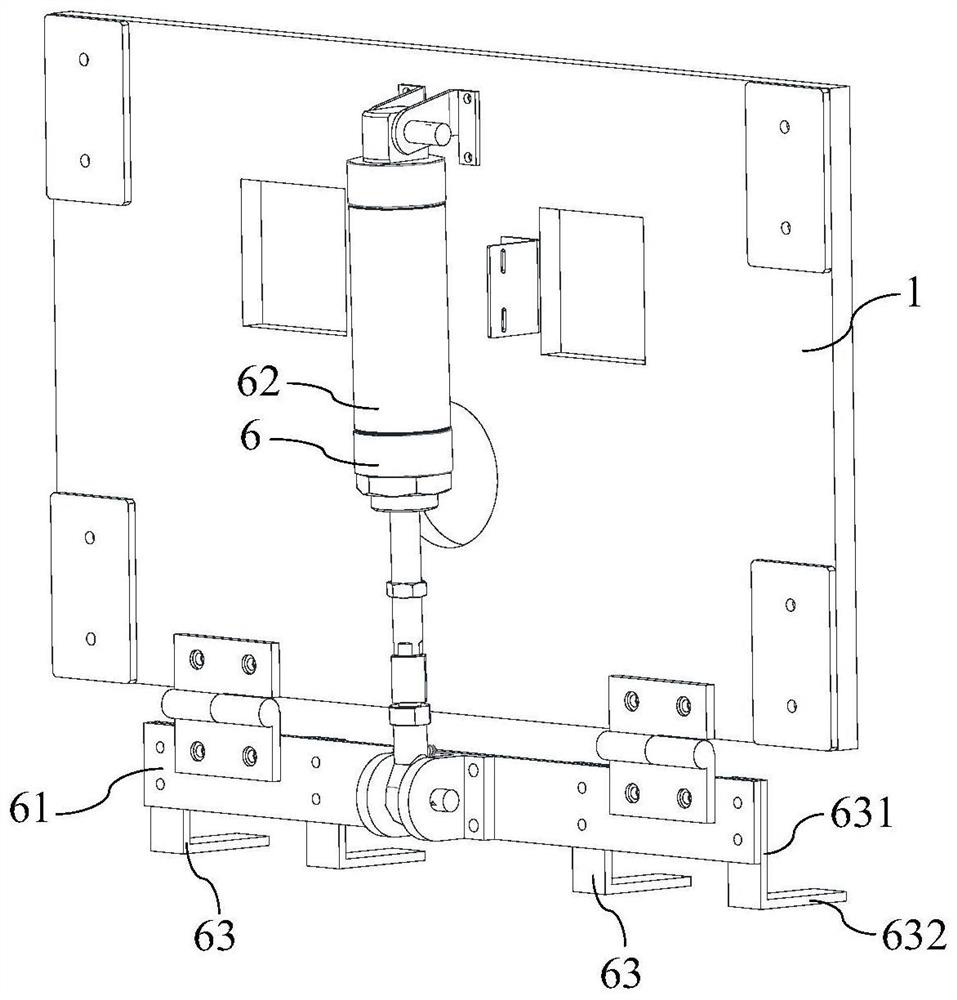

[0021] figure 1 It is a structural schematic diagram of the handling fixture in use according to the embodiment of the present invention. figure 2 The handling jig of the embodiment of the present invention is schematically shown in use. Such as figure 1 and figure 2 As shown, in the present invention, the transport fixture 100 is used to be installed on a transport device and transport a box-type product 200 , which includes a base 3 , a first clamping part 1 , a second clamping part 2 and an insertion arm 4 . Wherein, the first clamping part 1 and the second clamping part 2 are capable of clamping a box-type product 200, and are arranged on a base 3 for connecting with a conveying device. The first clamping part 1 and the second clamping part 2 can move relatively, and on the side of the first clamping part 1 away from the second clamping part 2, there is a The ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com