Automatic wire winding and binding machine

A winding and automatic technology, which is applied to the parts of the binding machine, binding materials, packaging, etc., can solve the problems of inconvenient winding operation, low winding efficiency, hurting people, etc., and achieve convenient winding operation , Winding is convenient, the effect of convenient winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

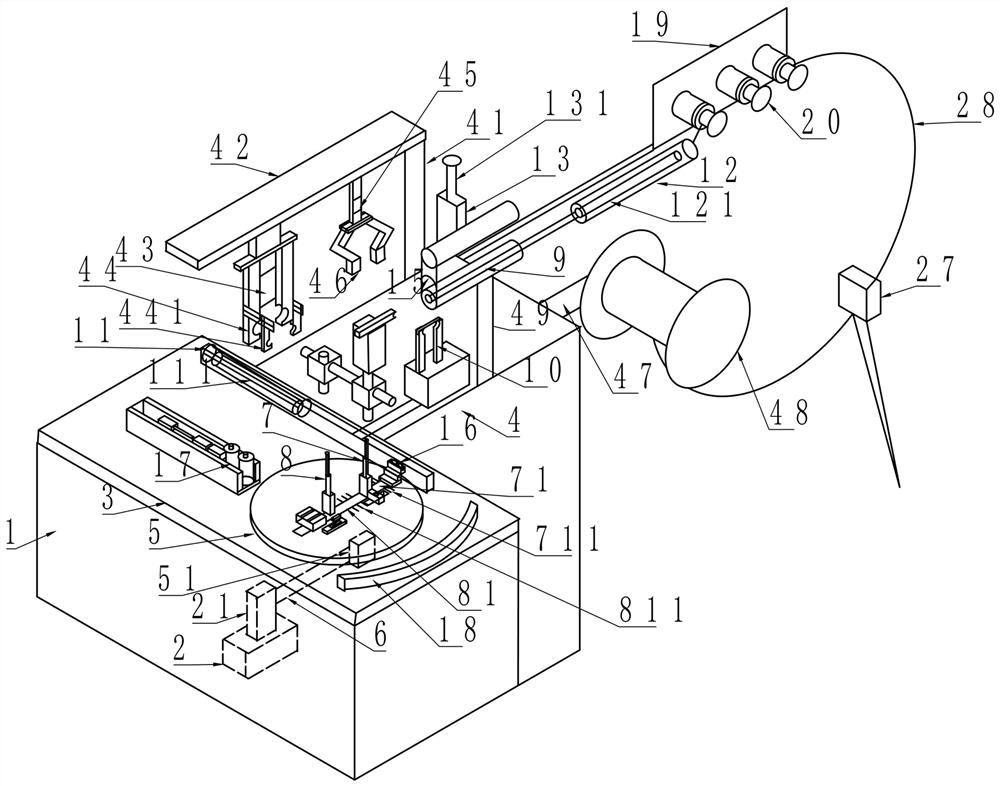

[0020] An automatic winding and binding machine, comprising a frame 1, a motor 2 is arranged in the frame 1, a first working platform 3 and a second working platform 4 are arranged on the frame 1, and a turntable 5 is arranged on the first working platform 3 , the rotating shaft 51 of the turntable 5 is connected with the driving shaft 21 of the motor 2 through the belt 6, and the turntable 5 is provided with two winding supports 7, 8; the second working platform 4 is provided with a first support 41, and the first support The outside of the crossbeam 42 of 41 is provided with the mobile clamp 44 driven by the clamp cylinder 43, the inner side is provided with the binding clamp 46 driven by the rotary cylinder 45, and the second working platform 4 is provided with the first push rod 111 driven by the first cylinder 11. The wire binding frame 10, the second support 49 of the second working platform is provided with the wire feeding telescopic rod 9 driven by the second push rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com