Preparation method of powder modified protein gypsum retarder

A gypsum retarder and powder modification technology, applied in the field of building materials, can solve the problems of low retardation efficiency, reduced strength, and high cost, and achieve high content of effective protein components, delayed setting time, and reduced centralized heat generation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

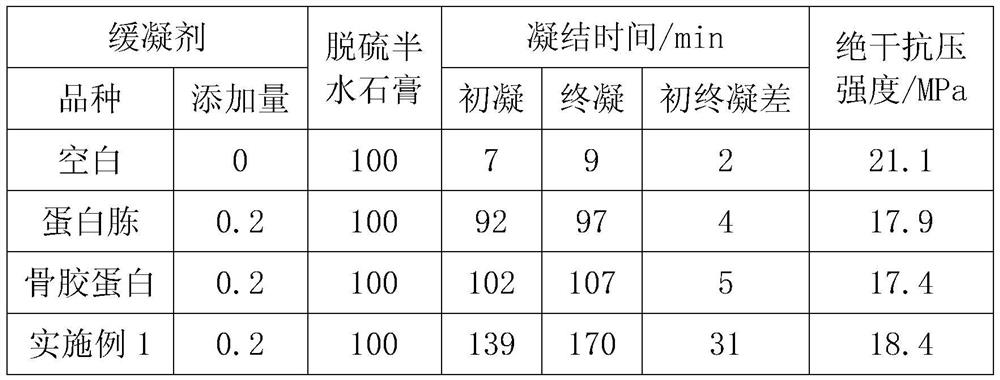

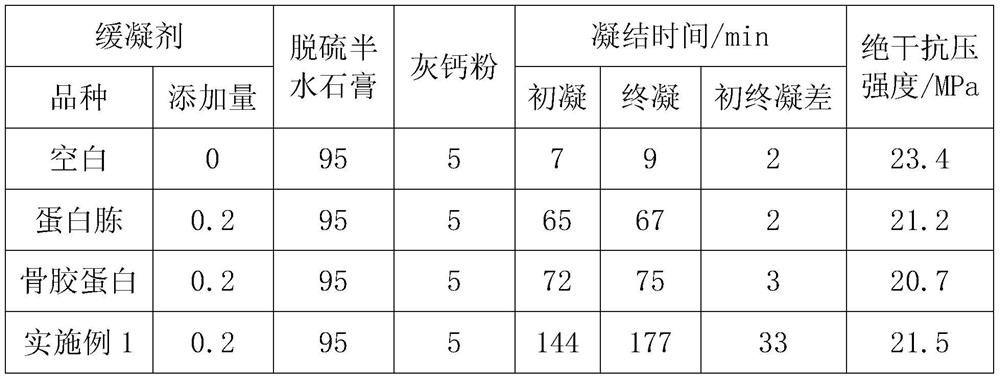

Examples

Embodiment 1

[0023] A preparation method of powder modified opal plaster retarder, comprising the following steps:

[0024] a. Acid hydrolysis: put 30 parts by mass of protein material, 10 parts by mass of 31% hydrochloric acid and 40 parts by mass of water into the reactor, and carry out the hydrolysis reaction for 3-4 hours at a temperature of 85-90° C. to obtain solid Acid hydrolyzed protein solution with a content of 35-40%;

[0025] b. Modification: Leave 60 mass parts of the acid hydrolyzed protein solution obtained in step a in the reactor, then add 25 mass parts of diethylenetriaminepentamethylene phosphonic acid, 1 mass part of styrenesulfonic acid, 4 mass parts Parts of hydroxyethyl acrylate are kept at a temperature of 55-60°C for 1-1.5 hours to obtain a mixture;

[0026] c. Neutralization: cool down the mixture obtained in step b to 35-45°C, then add 3 parts by mass of potassium tartrate and 5 parts by mass of calcium hydroxide, and neutralize the pH value to 7-9 to obtain mod...

Embodiment 2

[0035] A preparation method of powder modified opal plaster retarder, comprising the following steps:

[0036] a. Acid hydrolysis: put 35 parts by mass of protein material, 18 parts by mass of 31% hydrochloric acid and 45 parts by mass of water into the reactor, and carry out the hydrolysis reaction at a temperature of 85-90° C. for 3-4 hours to obtain solid Acid hydrolyzed protein solution with a content of 35-40%;

[0037] b. Modification: Leave 60 mass parts of the acid hydrolyzed protein solution obtained in step a in the reactor, then add 25 mass parts of diethylenetriaminepentamethylene phosphonic acid, 1 mass part of styrenesulfonic acid, 4 mass parts Parts of hydroxyethyl acrylate are kept at a temperature of 55-60°C for 1-1.5 hours to obtain a mixture;

[0038] c. Neutralization: cool down the mixture obtained in step b to 35-45°C, then add 3 parts by mass of potassium tartrate and 5 parts by mass of calcium hydroxide, and neutralize the pH value to 7-9 to obtain mod...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap