Building pile foundation and construction process thereof

A technology for construction piles and foundations, which is applied in the direction of foundation structure engineering, buildings, sheet pile walls, etc., can solve the problems of poor building stability, insufficient pile foundation bearing capacity, and small pressure transmission area, so as to increase the bearing strength and improve the resistance The effect of wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

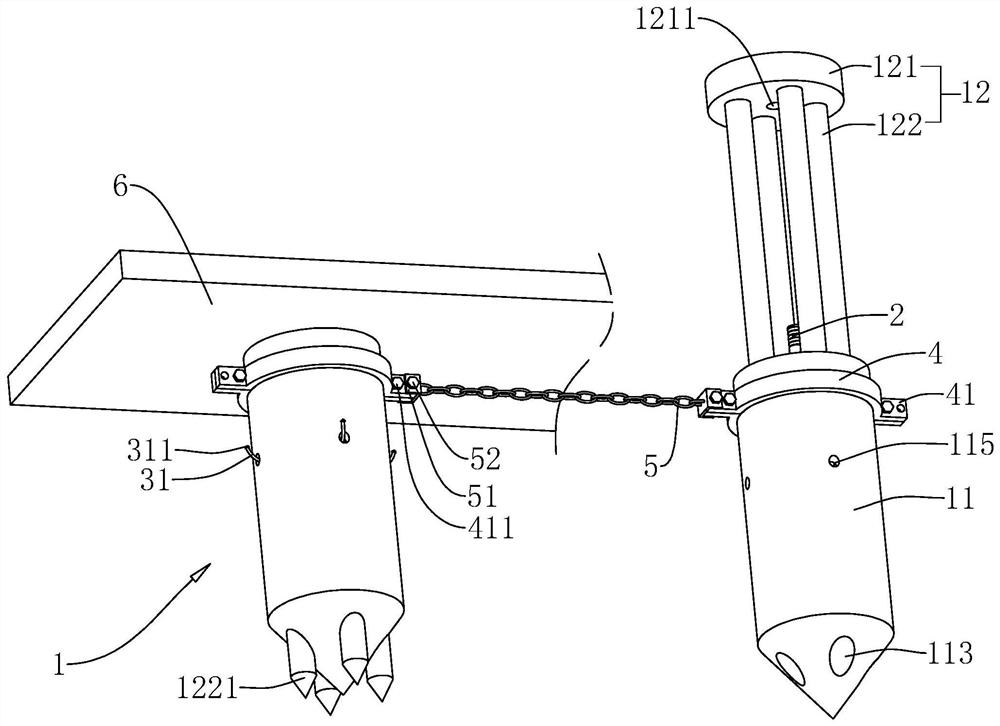

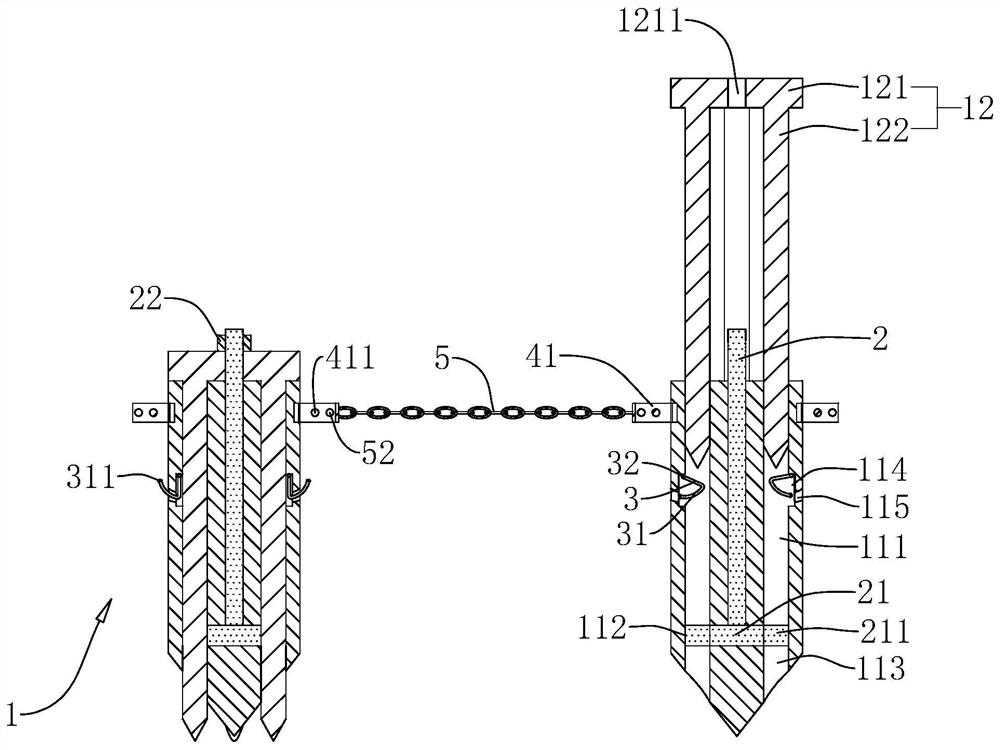

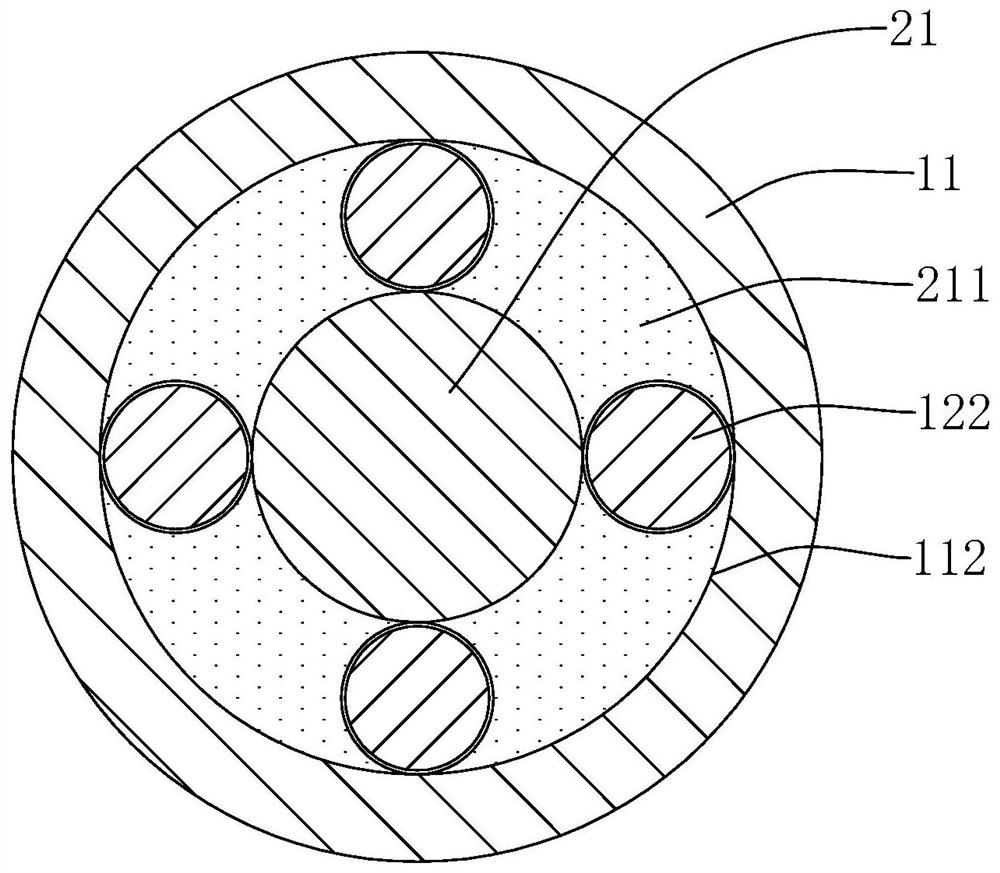

[0037] The following is attached Figure 1-3 The application is described in further detail.

[0038] A kind of building pile foundation, refer to figure 1 and figure 2 , including a plurality of pile foundations 1 and caps 6 vertically inserted in the soil around the pile, and the caps 6 are fixed on one end of the plurality of pile foundations 1 protruding from the ground. The pile foundation 1 includes a bottom pile 11 and a top pile 12 above the bottom pile 11. An undercut is arranged inside the bottom pile 11. The top pile 12 is used to drive the undercut to extend out of the bottom pile 11 and insert into the soil around the pile. The pile 11 and the top pile 12 are fixed by reinforcement components, and the pile foundation 1 is provided with a holding component, and the holding components of two adjacent pile foundations 1 are fixed by a chain component, so as to strengthen the bearing strength of the pile foundation 1 .

[0039]The bottom pile 11 is arranged in a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com