House building wall body structure and construction method

A technology for building walls and houses, used in building components, building structures, buildings, etc., can solve the problems of poor thermal insulation and moisture-proof performance of masonry walls, achieve better stability, improve practicability, and increase waterproof and thermal insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

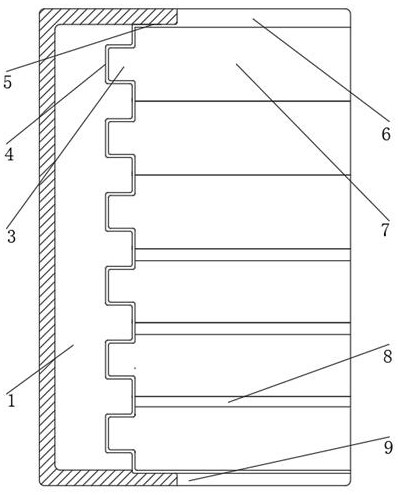

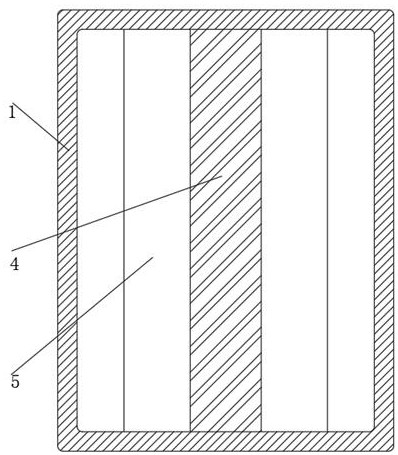

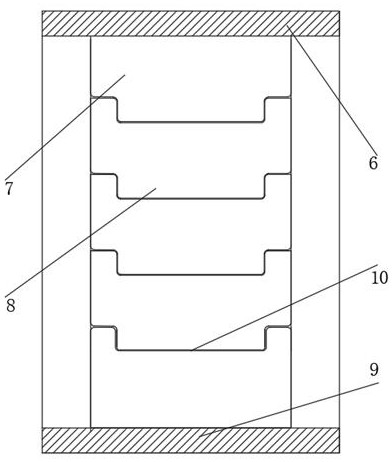

[0026] see Figure 1-5 , the present invention provides the following technical solutions: the building wall structure includes a main body of concrete wall 1 and a masonry brick wall 2, one side of the concrete wall 1 is provided with a second groove 5, and one side of the second groove 5 The first groove 4 is integrally formed, and the outer surface of the concrete wall 1 is fixedly connected with a lower baffle 9 through mud, and the upper surface of the lower baffle 9 is fixedly connected with a connecting brick 7 through mud, and the connecting brick at the top The upper surface of 7 is fixedly connected with the upper top plate 6 through mud, and the lower surface of the connecting brick body 7 is integrally formed with a second raised connecting portion 8, and the upper surface of the connecting brick body 7 is provided with a third groove 10, and the connecting brick body 7 One side of one side is integrally formed with a first protruding connecting portion 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com