Underground protective wall for municipal engineering

A protective wall and engineering technology, applied in safety devices, mining devices, mining equipment, etc., can solve the problems of insufficient pressure bearing capacity of protective walls, achieve strong pressure bearing capacity, improve bearing capacity, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

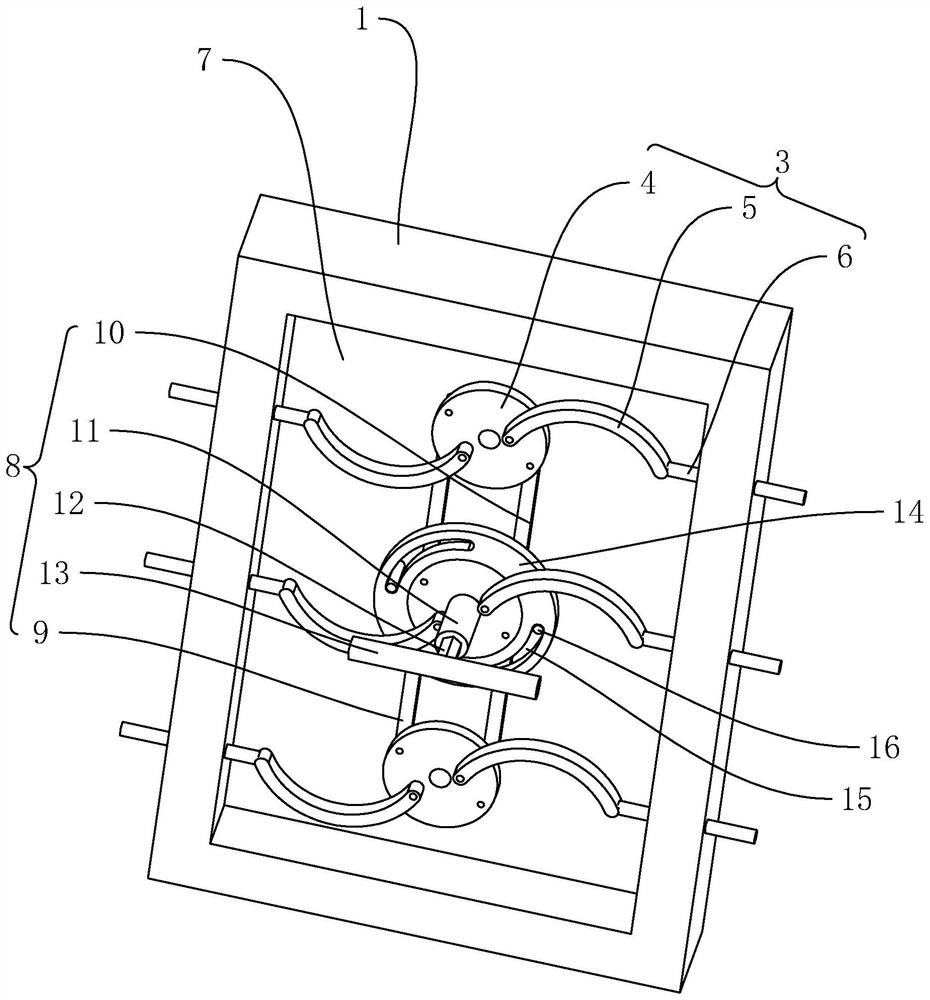

[0032] The following is attached Figure 1-4 The application is described in further detail.

[0033] The embodiment of the present application discloses an underground protective wall for municipal engineering.

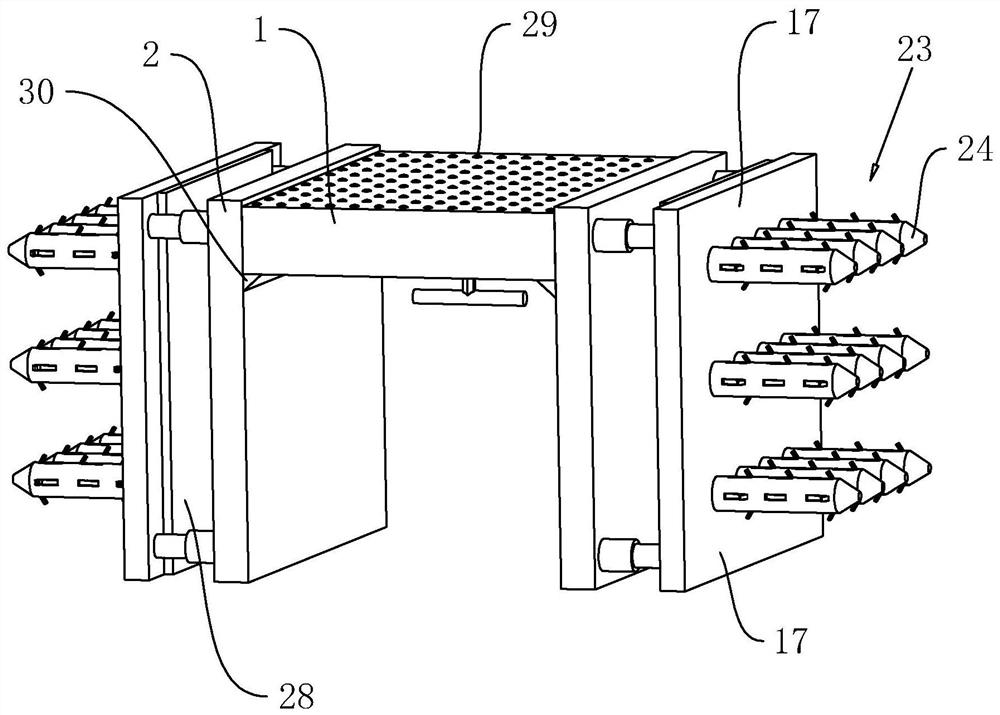

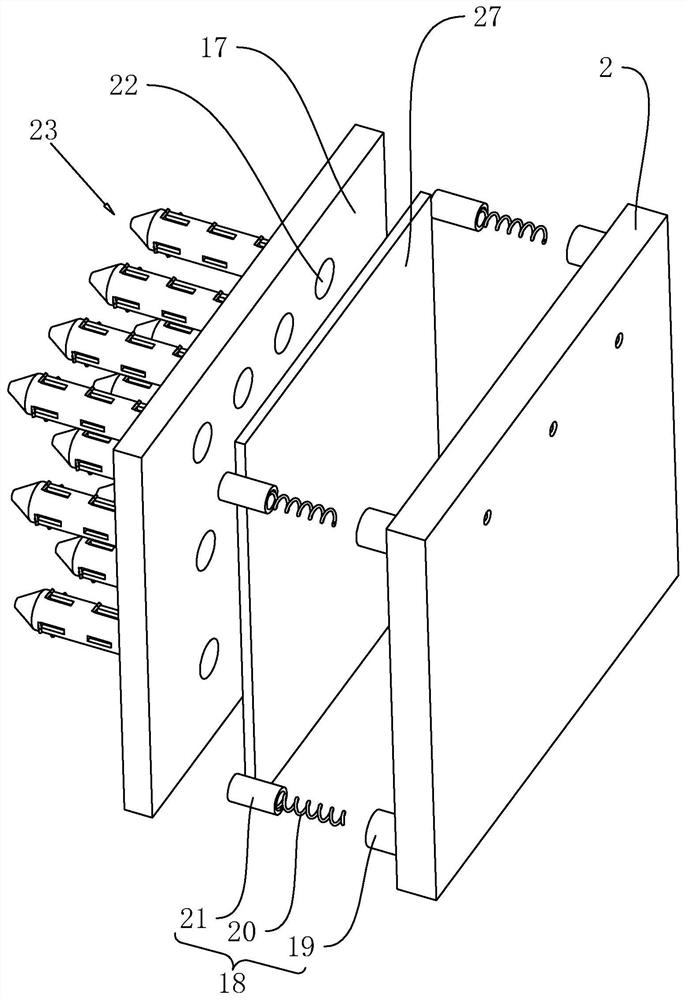

[0034] refer to figure 1 , an underground protective wall for municipal engineering, comprising a top plate 1, support plates 2 are arranged on both sides of the top plate 1, two support plates 2 are respectively fixed on both sides of an underground passage, and support plates are fixed on the opposite surfaces of the support plate 2 Block 30, the upper surface of the support block 30 abuts against the bottom surface of the top plate 1, the support block 30 strengthens the bearing capacity of the top plate 1, making the support of the top plate 1 more stable.

[0035] refer to figure 1A plurality of abutment blocks 29 are evenly spaced on the upper surface of the outer wall of the top plate 1. The upper surface of the abutment block 29 is arc-shaped, and the abut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com