Valve and pipeline connecting system simple and effective in sealing

A technology for connecting systems and valves, which is applied to flange connections, pipes/pipe joints/fittings, sliding valves, etc., and can solve problems such as loose connections and gas-liquid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

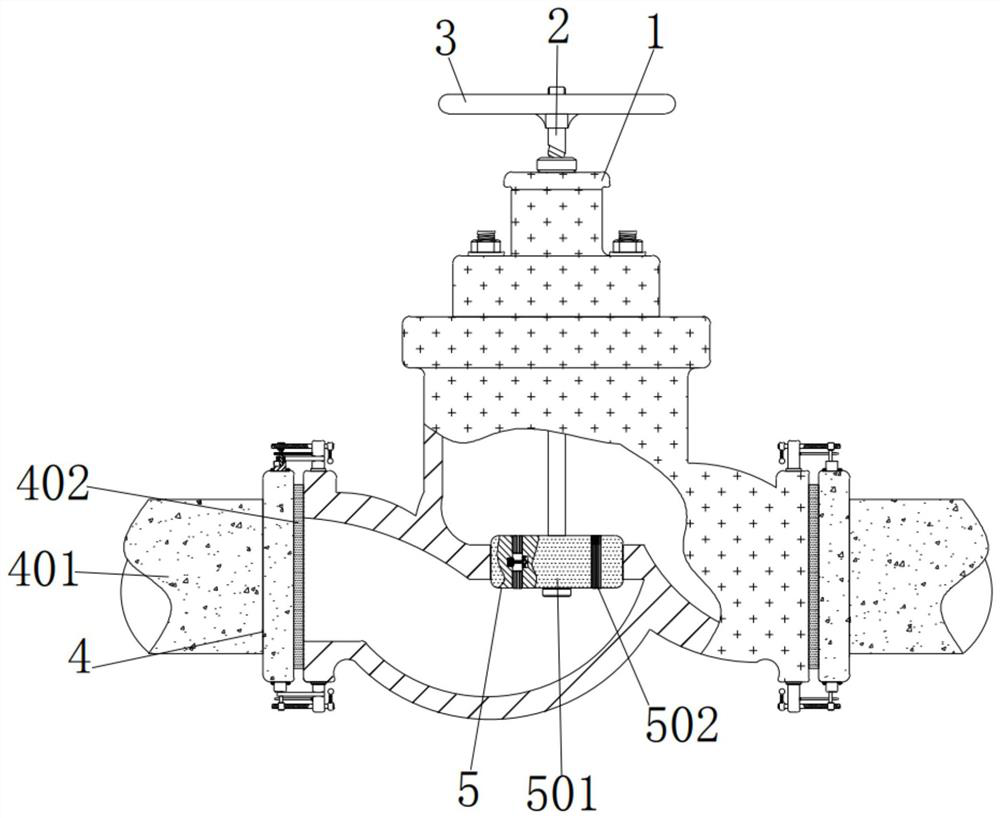

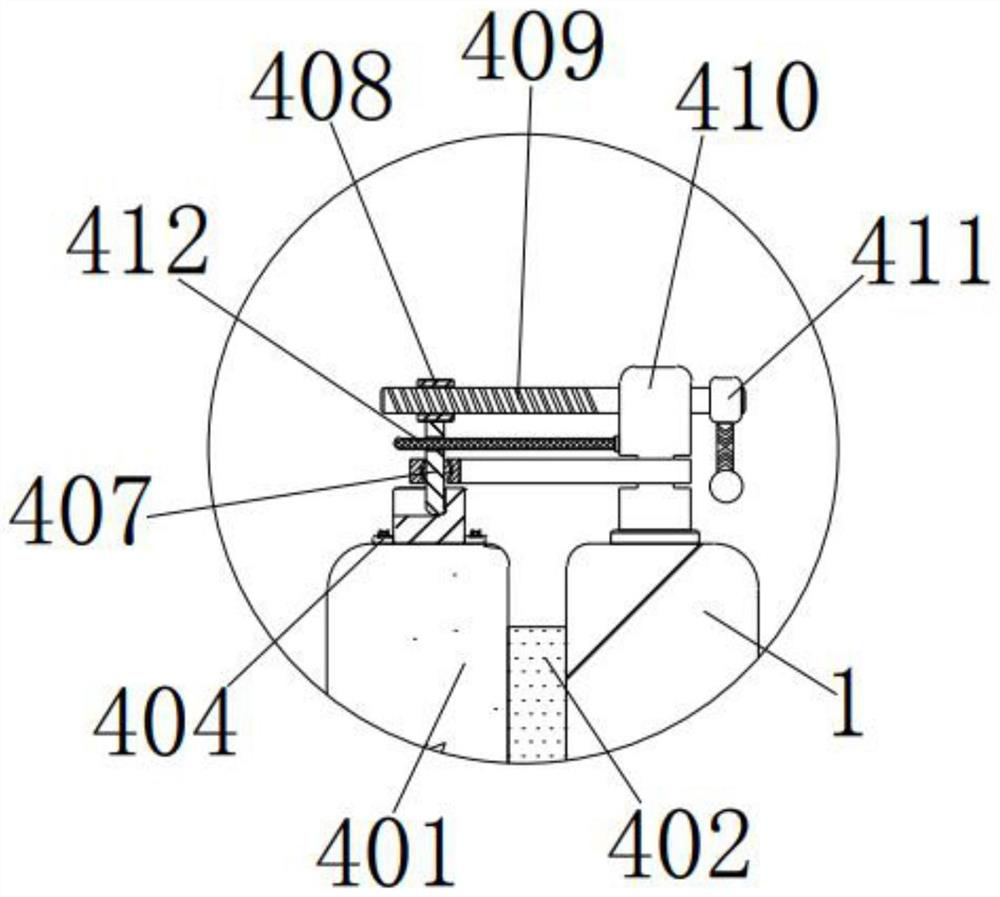

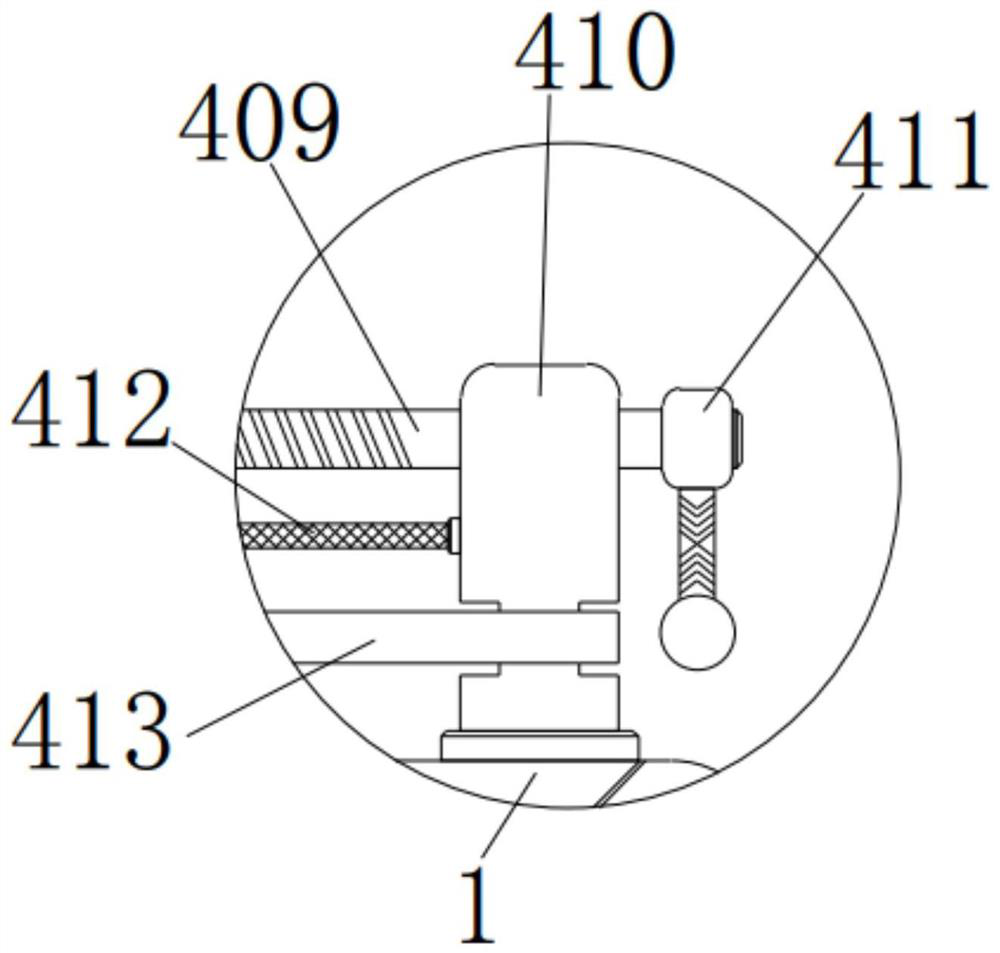

[0035]A valve and pipeline connection system with simple and effective sealing, including a valve body 1, a fixing mechanism 4 is installed on the lower left and right sides of the valve body 1, and the fixing mechanism 4 includes an external connecting pipe 401, a rubber pad 402, and a first vertical block 403 , ear plate 404, fixing bolt 405, card slot 406, first vertical bar 407, second vertical block 408, second threaded rod 409, third vertical bar 410, handle 411, first cross bar 412, curved bar 413, Through groove 414 and moving ball 415, the right end of the left external connecting pipe 401 is closely attached to the left end of the rubber pad 402, the right end of the rubber pad 402 is closely attached to the lower left end of the valve body 1, and the rubber pad 402 is connected to the external connecting pipe 401 and the valve body. The connection between 1 is sealed, the rubber pad 402 is made of fluorine rubber material, the upper and lower ends of the right side o...

Embodiment 2

[0037] As an option, see figure 1 , 4 And 5, a new type of linkage valve, an anti-leakage mechanism 5 is installed in the middle of the bottom of the valve body 1, and the anti-leakage mechanism 5 includes a first valve flap 501, a rubber block 502, a second valve flap 503, a fixed block 504, a triangular block 505, The second cross bar 506, the compression spring 507, the cross block 508, the second vertical bar 509 and the groove 510, the middle inner wall of the first valve flap 501 is connected to the lower outer wall of the first threaded rod 2 through a sealed bearing, and the first screw thread The rod 2 drives the first valve flap 501 to move up and down, the left and right ends of the first valve flap 501 are fixedly connected to the inner side of the rubber block 502, and the outer sides of the rubber block 502 are fixedly connected to the inner side of the second valve flap 503. The outer walls of the first valve disc 501, the rubber block 502 and the second valve ...

Embodiment 3

[0040] An application of a valve and pipeline connection system with simple and effective sealing. When using this new type of linkage valve, firstly, the external connecting pipes 401 on both sides are manually attached to the inlet and outlet on the left and right sides of the valve body 1 through rubber pads 402. At the position, the ear plates 404 on both sides are fixed on the external pipe 401 by fixing bolts 405 so that the first vertical block 403 is fixed on the external pipe 401, and the turning handle 411 drives the second threaded rod 409 to rotate in the third vertical rod 410 through the bearing. Make the second vertical block 408 drive the first vertical bar 407 to move inwardly on the outer wall of the second cross bar 412, and the first vertical bar 407 moves inwardly in the draw-in slot 406 on the first vertical block 403 to the outer connecting pipe 401 to the right The force makes the connection between the external connecting pipe 401 and the valve body 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com