High-strength damp-proof composite board

A composite board, high-strength technology, applied in the direction of sheet/board, thin board connection, connecting components, etc., can solve the problems of the failure of the moisture-proof material of the interlayer, and the moisture-proof composite board does not have the moisture-proof function, and achieves ingenious structure, improved strength, and extended use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

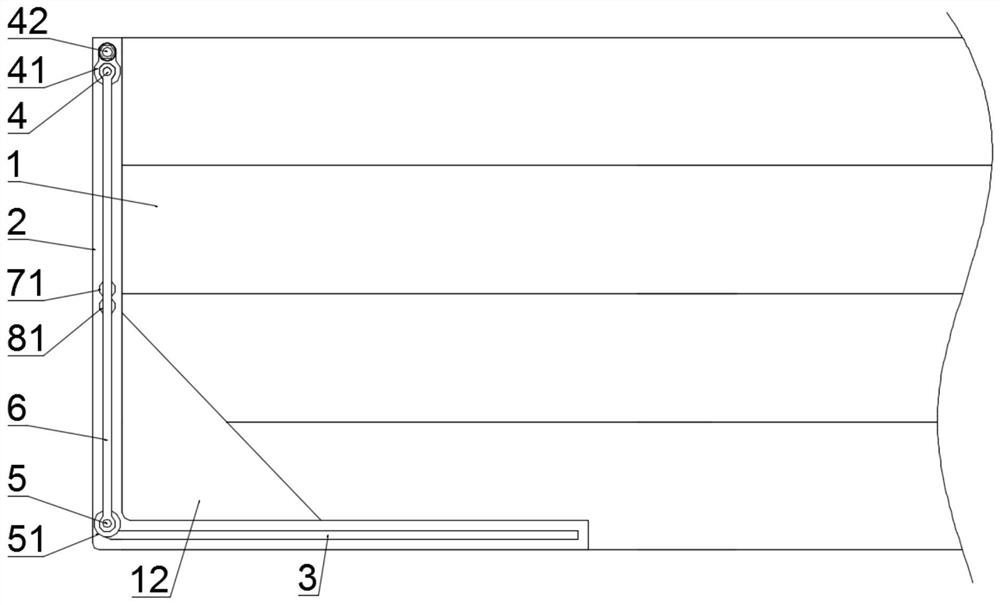

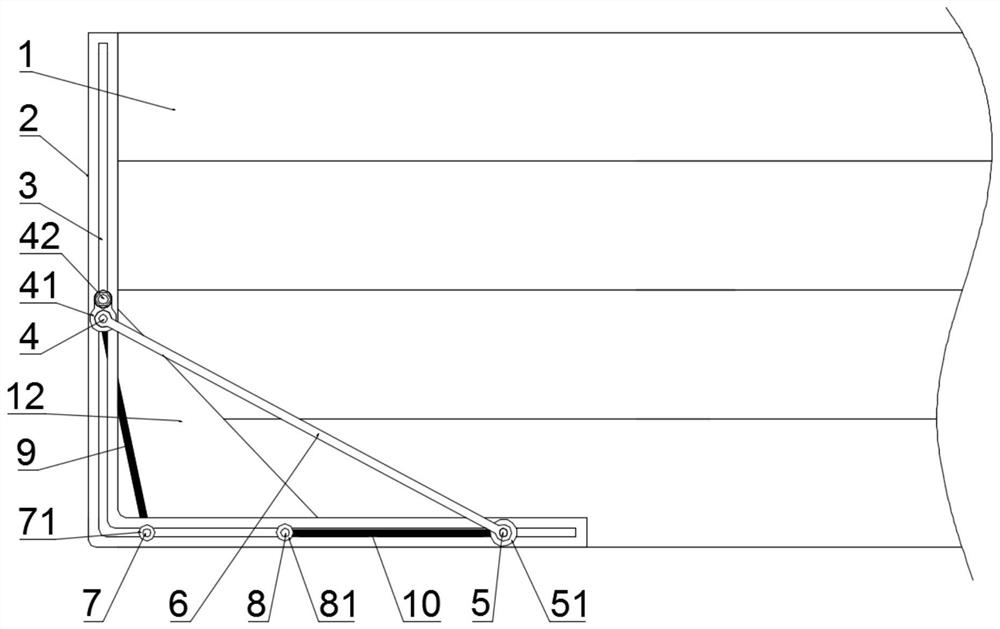

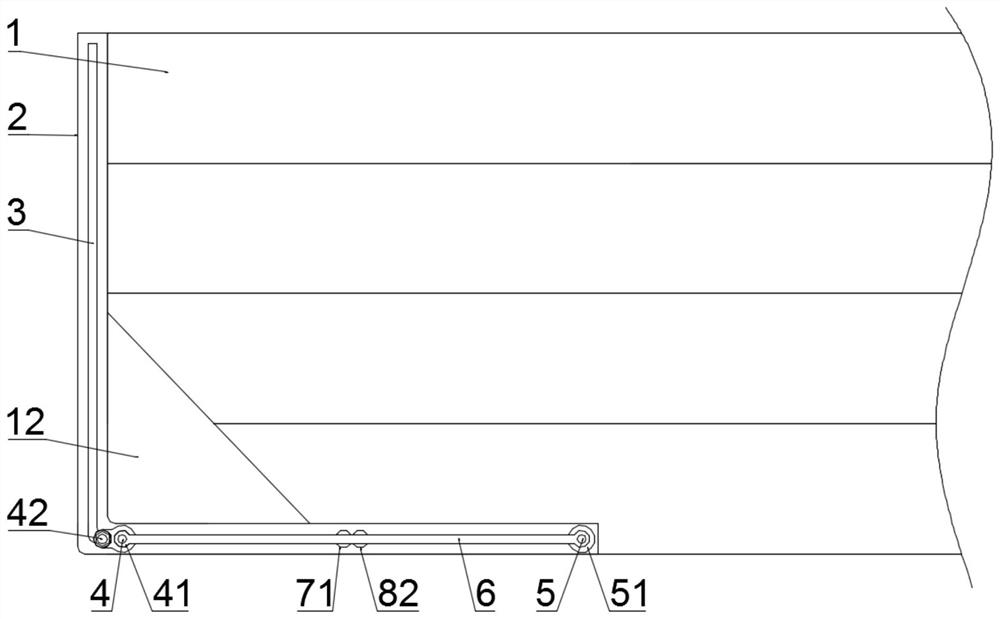

[0032] like Figure 1-6 As shown, a high-strength moisture-proof composite panel includes a composite panel body 1 and a right-angle frame 2, and the right-angle frame 2 is attached to the front side and the rear side of the end of the composite panel body 1, and is located between the front side and the rear side. The two right-angle frames 2 on the rear side are fixedly connected to each other through the fixing member 201. The right-angle frame 2 is provided with a right-angle through groove 3, and the right-angle through groove 3 is provided in order to slide along the right-angle through groove 3. The first slide bar 4, the second slide bar 7, the third slide bar 8 and the fourth slide bar 5 are moved, and a connecting rod 6 is arranged between the first slide bar 4 and the fourth slide bar 5. The two ends of the rod 6 are respectively hinged with the first sliding rod 4 and the fourth sliding rod 5, and the first baffle plate 9 is fixedly connected between the first slid...

Embodiment 2

[0039] like Figure 7 and 8 As shown, on the basis of Example 1, the right-angled frame 2 located on the different composite sheet bodies 1 is provided with snap-in mechanisms that are quickly connected to each other. Specifically, the snap-in mechanisms include fixedly arranged The fixed block 13 at the bottom of the right-angle frame 2, the fixed block 13 is provided with a through hole 14, and the upper part of the right-angle frame 2 is fixedly provided with a fixed cross bar 15, and the fixed cross bar 15 passes through a mobile plate 16 to move The plate 16 is connected to the surface of the right-angle frame 2 through a first spring 18, and the other end of the fixed cross bar 15 is fixedly connected with a protrusion 19 for preventing the moving plate 16 from breaking away from the fixed cross bar 15. The upper part of the moving plate 16 is formed with a limiting block 17 that can pass through the through hole 14 . The limiting block 17 is in the shape of a flat side...

Embodiment 3

[0042] like Figure 9 and 10 As shown, on the basis of Example 2, the right-angle frame 2 is provided with a plug-in device for inserting into the composite panel body 1 to increase the firmness of the connection with the composite panel body 1, specifically, the The plug-in device includes a vertical rod 20 fixedly arranged on the right-angle frame 2 in a vertical direction, and the vertical rod 20 is hinged with a protruding thorn 22 arranged obliquely downward, and the protruding thorn 22 is connected with the second spring 22 to The uprights 20 are connected.

[0043] When the composite panel body 1 needs to be installed on the right-angle frame 2, the composite panel body 1 can be directly pressed down to fit the right-angle frame 2. The setting can effectively prevent the separation of the composite board body 1 and the right-angle frame 2, and make the connection between the two firm.

[0044] Preferably, both the top end of the upright rod 20 and the inclined lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com