Ceiling decorative lamp strip structure

A technology for ceilings and light strips, applied in building components, lighting devices, lighting devices, etc., can solve the problems of destroying the integrity of patterns on the ceiling, affecting the aesthetics and cleanliness of the ceiling, and poor aesthetics and cleanliness of the ceiling. Achieve the effect of simple and stable overall structure, reduce glare and ensure aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

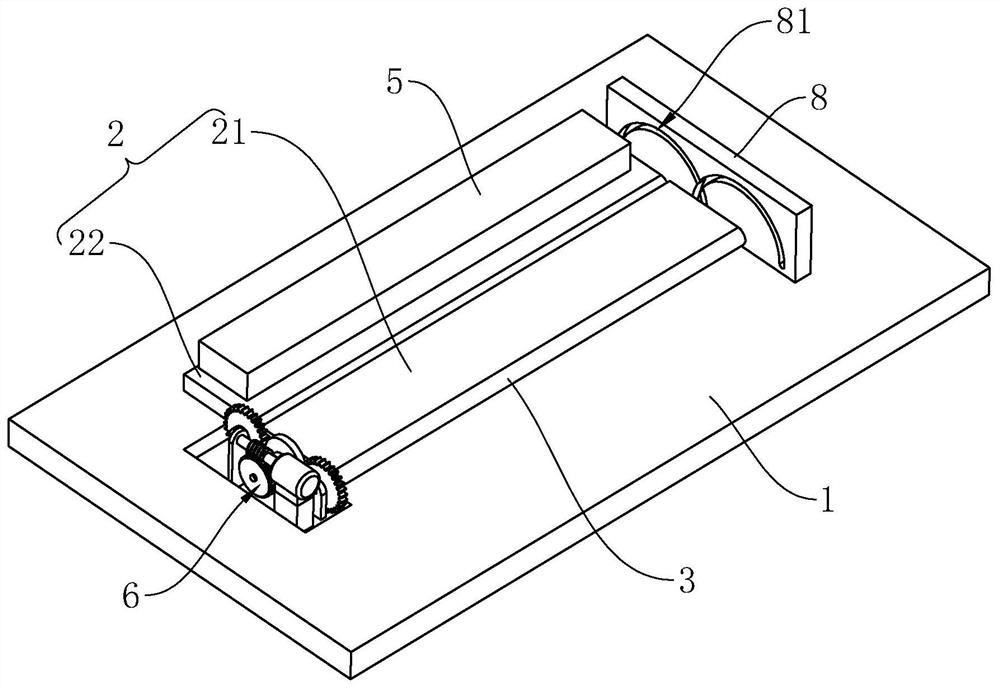

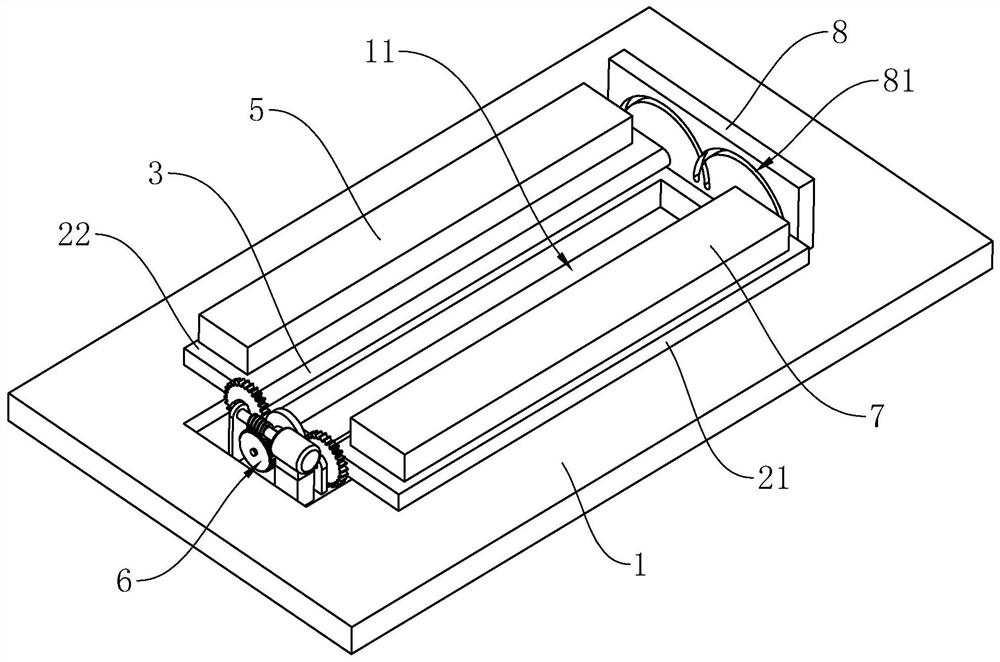

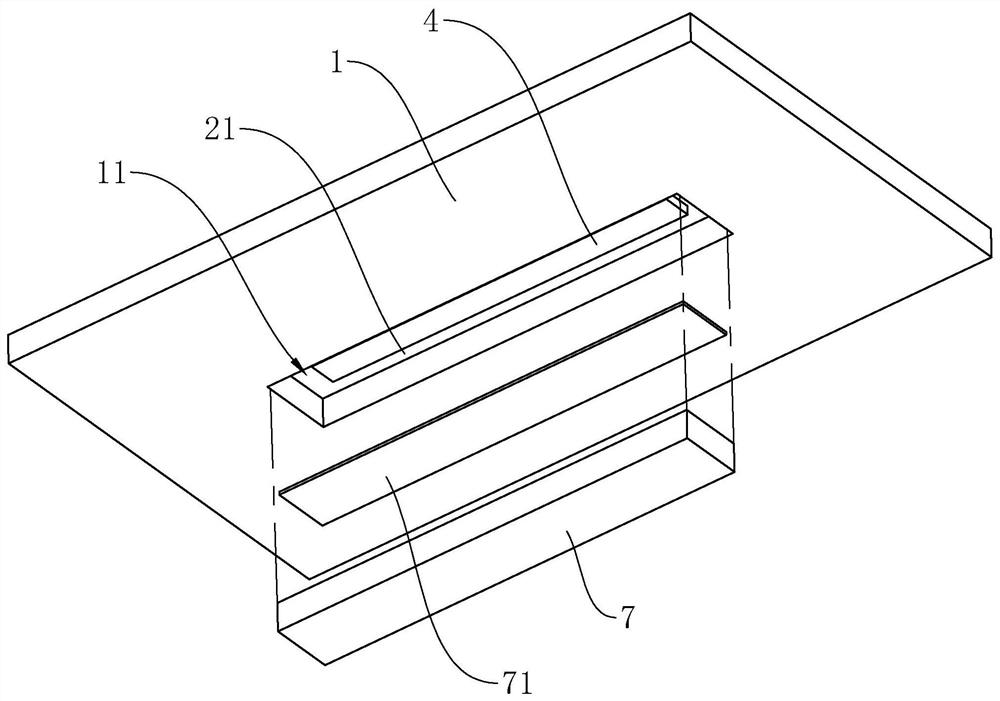

[0042] refer to figure 1 and figure 2 The structure of the ceiling decorative light belt includes a ceiling 1 arranged on the indoor roof. The ceiling 1 is generally installed on the keel of the indoor roof, and can also be installed on the indoor roof by hanging; the ceiling 1 is pre-opened with an installation groove 11. The groove 11 is arranged in a rectangular shape, and the ceiling 1 is provided with two mounting plates 2, the two mounting plates 2 are respectively located on both sides of the width direction of the mounting groove 11, and the mounting plates 2 are arranged along the length direction of the mounting groove 11; One end is fixed with a hinge shaft 3 , and the hinge shaft 3 is rotatably connected with the ceiling 1 so that the mounting plate 2 can rotate on the ceiling 1 .

[0043] refer to figure 2 and image 3, for the convenience of description, one of the mounting plates 2 is set as the first mounting plate 21, and the other mounting plate 2 is set...

Embodiment 2

[0053] The difference between this embodiment and embodiment 1 is: refer to Figure 8 , the driving mechanism 6 includes two transmission gears 66, and the two transmission gears 66 are respectively fixed on the two hinged shafts 3; a rack 67 is arranged below the two transmission gears 66, and the rack 67 is arranged along the width direction of the installation groove 11 set, and the rack 67 is slidably connected to the ceiling 1, and the rack 67 can slide along the width direction of the installation groove 11 on the ceiling 1. One side of the rack 67 is provided with a second drive motor 68, and a second transmission assembly 69 is provided between the second drive motor 68 and the rack 67, and the second drive motor 68 can drive the rack 67 to slide through the second transmission assembly 69. .

[0054] refer to Figure 8 , the two transmission gears 66 can mesh with the rack 67, and the center distance between the two transmission gears 66 is greater than the length o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com