A Mesoscopic Structure Design Method Guided by Force Flow

A mesoscopic structure and design method technology, applied in design optimization/simulation, computer-aided design, calculation, etc., can solve problems such as the mismatch of stress distribution in mesoscopic structural unit cells, improve sound absorption performance, increase specific strength, The effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

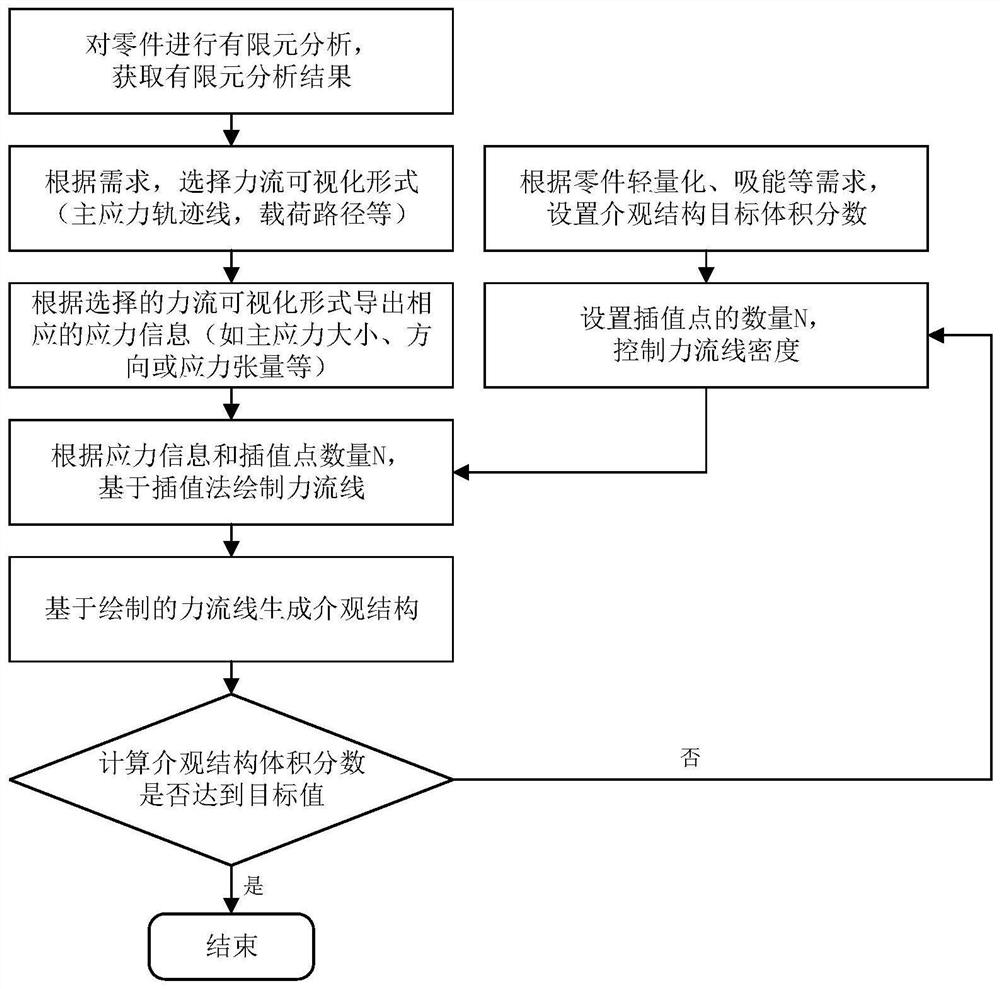

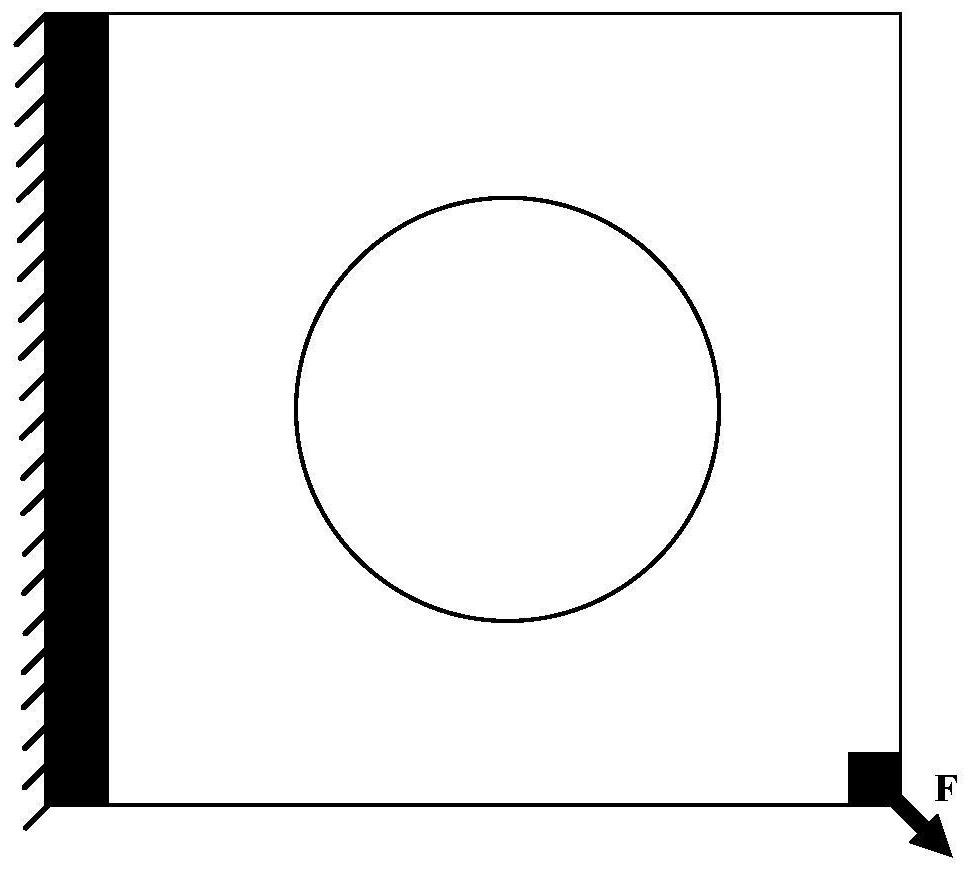

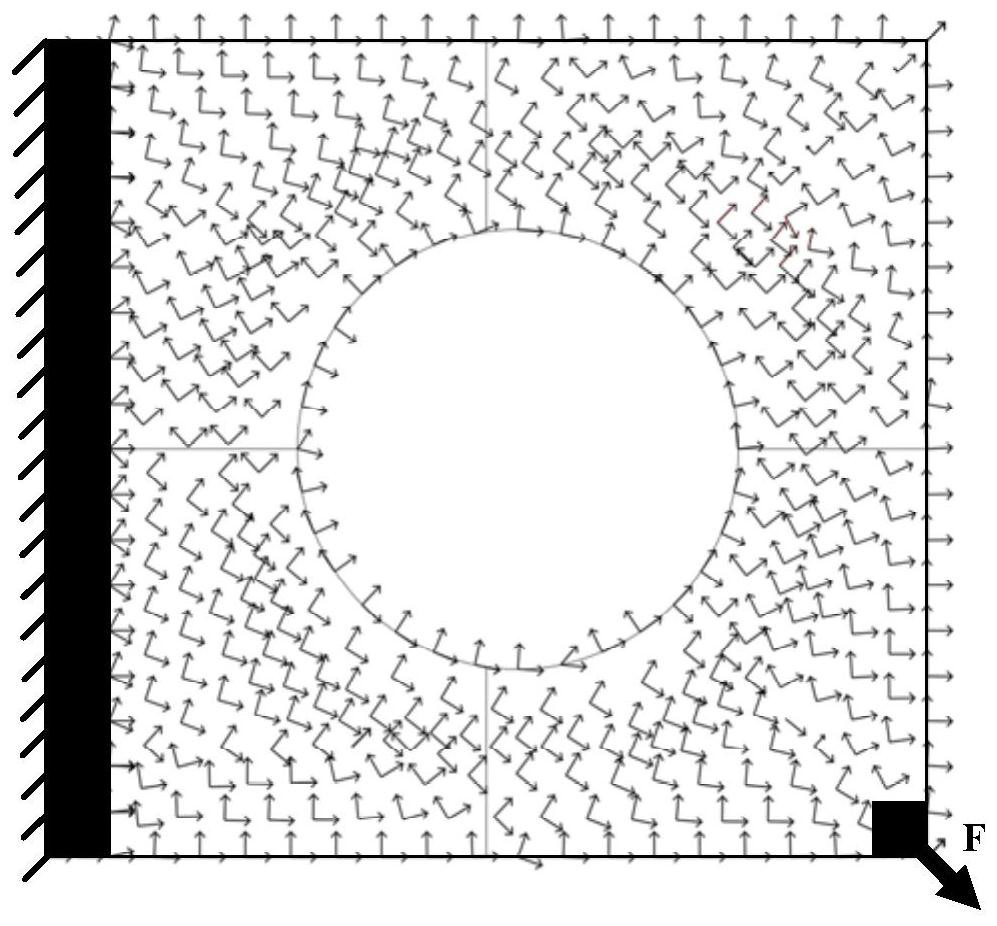

[0058] Taking the mesoscopic structure design of a flat square circular hole plate as an example, as figure 2 As shown, the load condition of the plate is: the left side is fixedly constrained, and the lower right corner is subjected to a concentrated force load in the direction of -45°. The internal mesoscopic structure of the plate is designed to improve its structural strength. The following examples are respectively selected based on the principal stress trajectory and Mesostructure design with constant load transfer path.

[0059] 1) Mesoscopic structure design based on principal stress trajectory

[0060] (a) Establish a finite element analysis model according to the load and boundary conditions of the square circular hole plate, and obtain the finite element stress analysis results;

[0061] (b) Extract the X, Y, and Z components of the three principal stress directions of all nodes based on the finite element analysis results, and draw the principal stress directions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com