Picoliter-scale single droplet generation method and device

A production method and a production device technology, which are applied to chemical instruments and methods, liquid separation into beads and granulation, measuring tubes/pipettes, etc., can solve the problems of large difference in results, difficult control, high cost, etc., and achieve liquid The effect of high droplet production efficiency, improved control accuracy and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

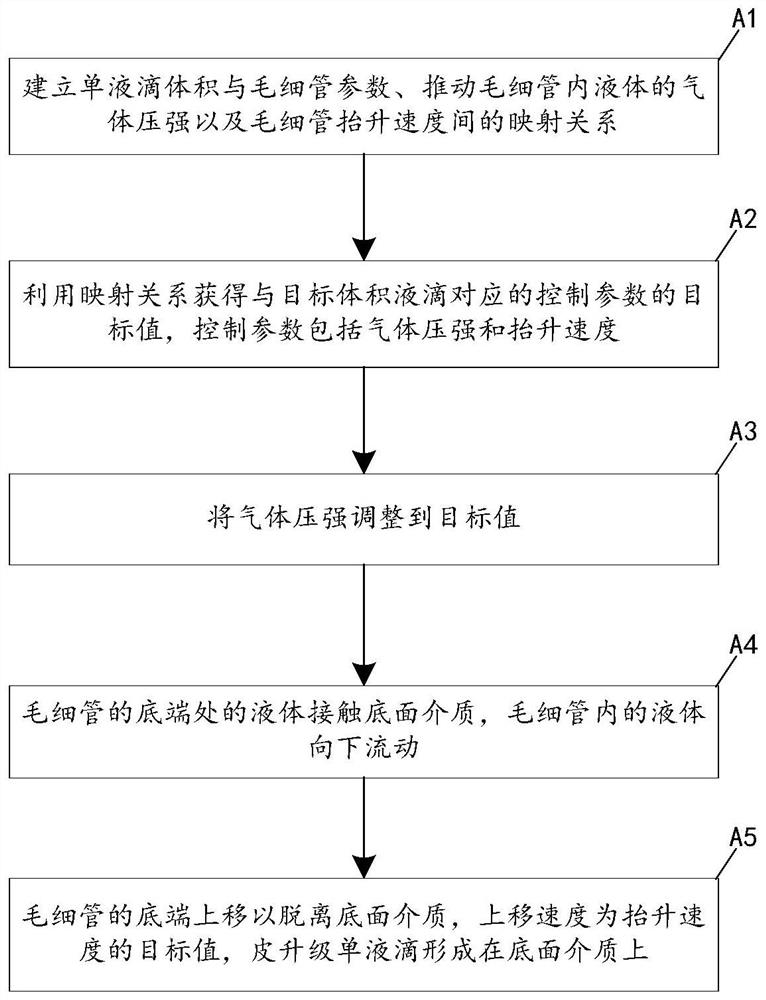

[0035] figure 1 A flow chart of the method for producing a picoliter single droplet in Embodiment 1 of the present invention is schematically shown, as figure 1 As shown, the method for producing a picoliter single droplet comprises the following steps:

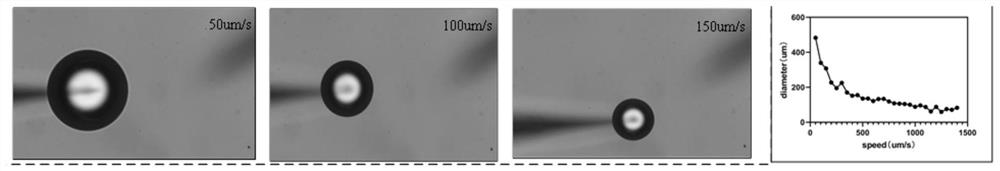

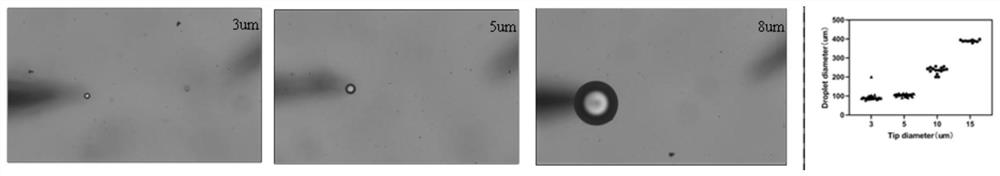

[0036] (A1) By studying the correlation between the volume of a single droplet and the inner diameter of the bottom of the capillary, the lifting speed of the capillary, and the gas pressure pushing the liquid in the capillary, such as Figure 2-4 As shown, thereby establishing the mapping relationship between the volume of a single droplet and the capillary parameters, the gas pressure pushing the liquid in the capillary, and the capillary lifting velocity;

[0037] (A2) Using the mapping relationship to obtain the target value of the control parameter corresponding to the target volume droplet, the control parameter includes the gas pressure and the lifting speed;

[0038] (A3) adjusting the gas pressure to a target valu...

Embodiment 2

[0056] An application example of the method and device for generating a picoliter single droplet according to Embodiment 1 of the present invention in single cell detection.

[0057] In this application example, the capillary is made of borosilicate glass, one end of which is open to the gas source, and the inner diameter of the bottom of the capillary is 20 μm;

[0058] The pressure control unit is arranged between the capillary and the gas source, and is used to adjust the pressure of the gas entering the capillary;

[0059] The method for producing a picoliter single droplet according to an embodiment of the present invention comprises the following steps:

[0060] (A1) Establish a mapping relationship between the volume of a single droplet and capillary parameters, the gas pressure that promotes the liquid in the capillary, and the capillary lift velocity:

[0061] V is the drip volume, R is the inner diameter of the capillary bottom, ω is the taper of the capillary bot...

Embodiment 3

[0069] An application example of the method and device for generating a picoliter single droplet according to Embodiment 1 of the present invention in single cell detection.

[0070] In this application example, the capillary is made of borosilicate glass, one end of which is open to the gas source, and the inner diameter of the bottom of the capillary is 15 μm;

[0071] The pressure control unit is arranged between the capillary and the gas source, and is used to adjust the pressure of the gas entering the capillary;

[0072] The method for producing a picoliter single droplet according to an embodiment of the present invention comprises the following steps:

[0073] (A1) Establish a mapping relationship between the volume of a single droplet and capillary parameters, the gas pressure that promotes the liquid in the capillary, and the capillary lift velocity:

[0074] V is the drip volume, R is the inner diameter of the capillary bottom, ω is the taper of the capillary bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com