Droplet generation method and device

A method for producing liquid droplets, which is applied to chemical instruments and methods, measuring tubes/pipettes, and laboratory containers. It can solve problems such as inability to release, limited detection methods, and small specific surface area of liquid droplets. Improve control accuracy, increase production efficiency, and achieve high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

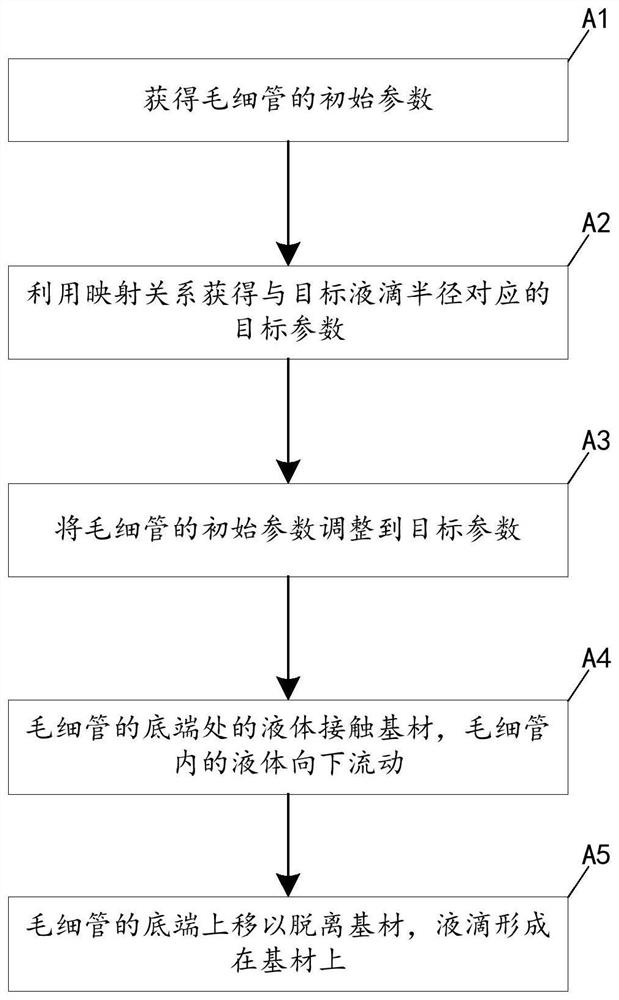

[0033] figure 1 Schematically provides a flow chart of the droplet generation method in Embodiment 1 of the present invention, as figure 1 Shown, the generation method of described droplet comprises the following steps:

[0034] (A1) Obtaining initial parameters of the capillary, the initial parameters including the inclination angle of the capillary relative to the substrate;

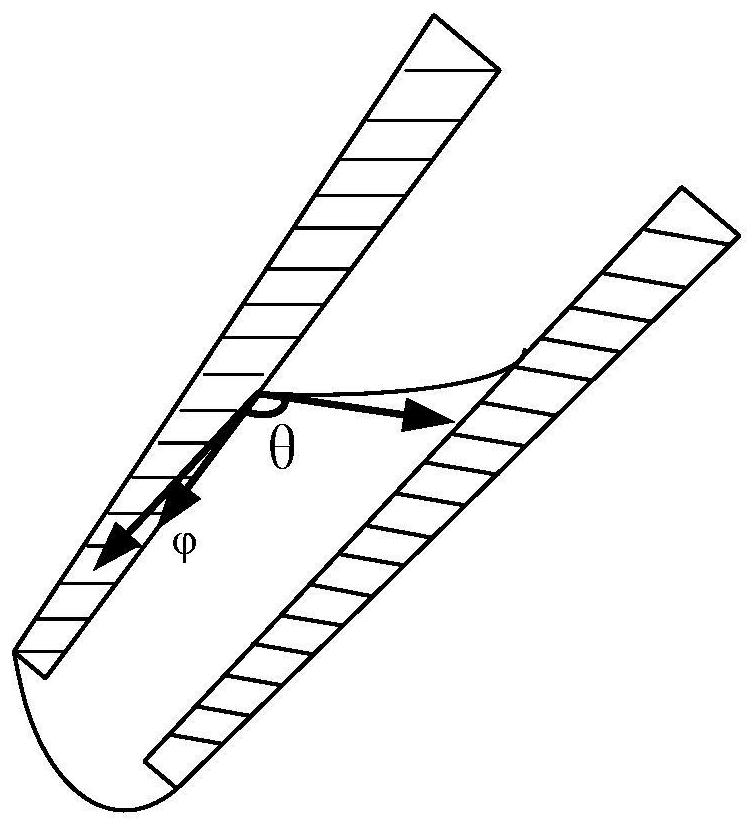

[0035] figure 2 Schematically shows the cross-sectional structure of the capillary, such as figure 2 As shown, the capillary is a hollow structure with openings at both ends, the liquid level in the capillary is horizontal, and the liquid in the suspended capillary will not drip when it is not subjected to external force; is the angle between the central axis of the capillary and the generatrix of the inner surface, and θ is the maximum value of the angle between the generatrix and the liquid surface inside the capillary;

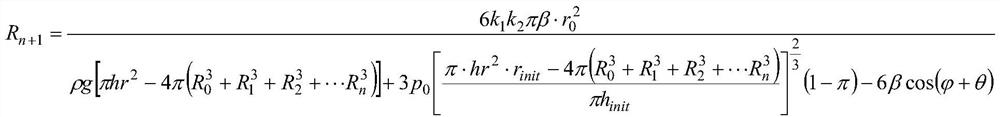

[0036] (A2) Utilize the mapping relationship to obtain the target parame...

Embodiment 2

[0073] An application example of the droplet generation method and device according to Embodiment 1 of the present invention in single cell detection.

[0074] In this application example, the inner and outer walls of the capillary are treated as follows: soak the capillary in 8% to 12% NaOH solution and Piranha solution for 2 to 10 minutes each, and then soak the capillary in 18% to 22% NaOH solution. Put in the ethanol solution of chlorodimethylsilane for 1 to 2 hours, wash with clean water, and then place the capillary in an oven at 100 to 150 degrees and bake for 30 to 60 minutes to remove stress.

[0075] The surface treatment of the substrate is as follows:

[0076] After mixing the silica sol and the nano-silica solution modified by sulfonic acid groups in a certain ratio (preferably 1:16), coat it on the surface of the substrate, and bake it in an oven at 100-150 degrees for 30-60 minutes; the substrate The glass coefficient k of the surface 1 = 0.89.

[0077] Use t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com