Wire spool for carbon fiber wires

A carbon fiber wire and spool technology, which is applied in the field of electric equipment, can solve the problems that the cable usage is not large, the transportation is inconvenient, and the space is occupied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

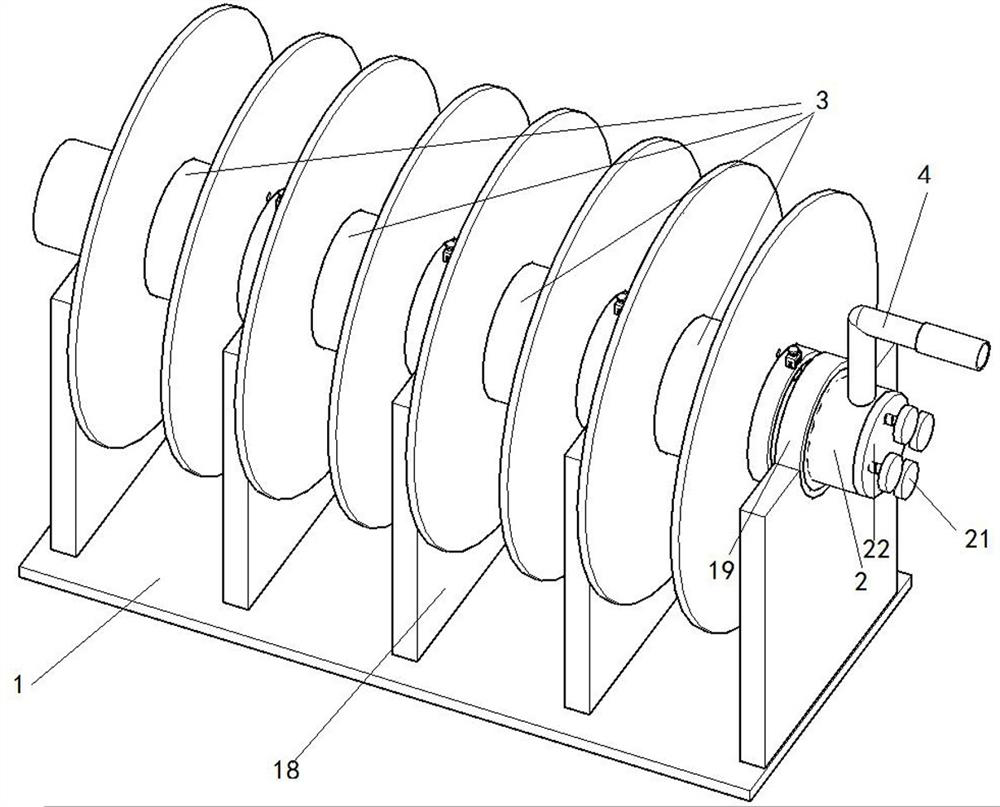

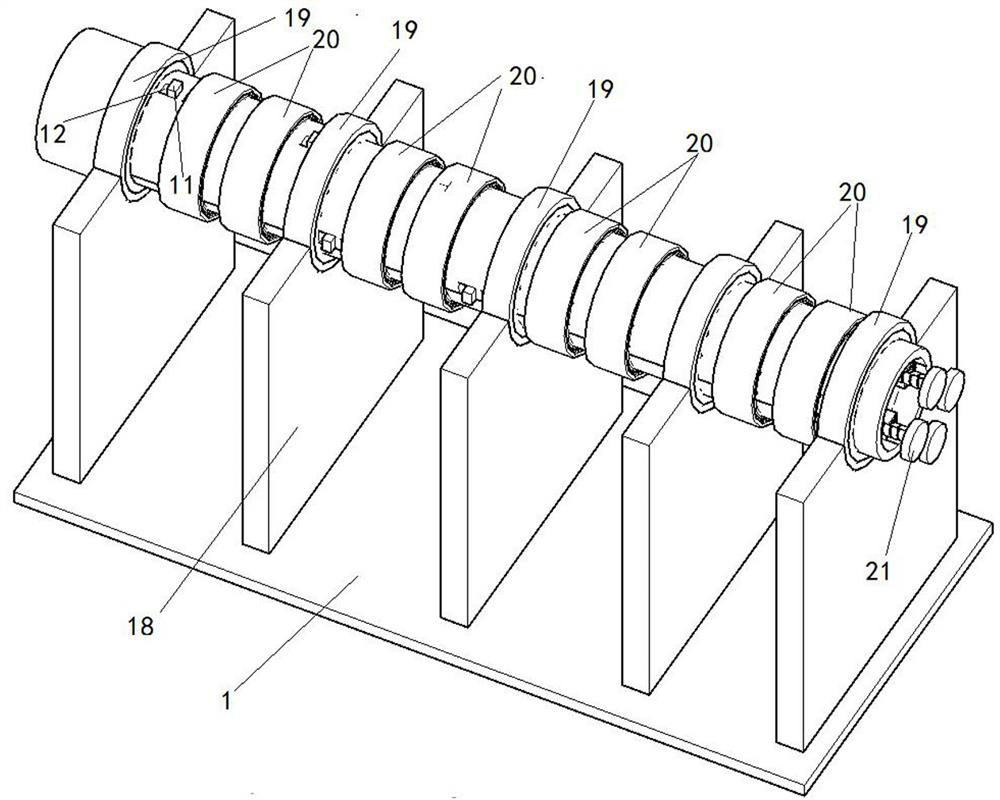

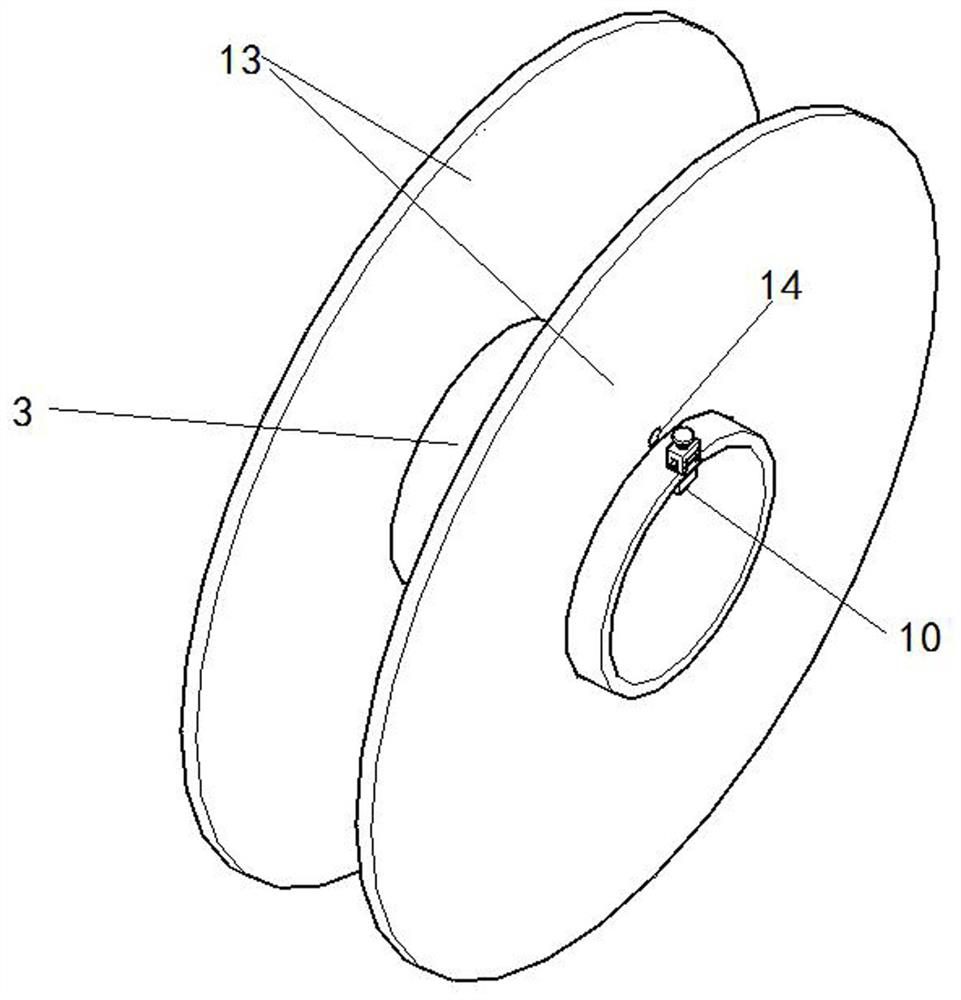

[0027] Such as Figure 1-7 Shown is the first embodiment of the present invention, a winding reel for carbon fiber wires, including a base 1, the base 1 is a cuboid plate-shaped structure, the base 1 is rotated and connected to the shaft 2, and the connection method is: vertical welding on the base 1 five risers 18, such as figure 1 with figure 2 As shown, the top of the vertical plate 18 is machined with an arc-shaped groove by a lathe, the inner shell of the arc-shaped groove is glued to the bearing one 19, and the shaft 2 is inserted into the bearing one 19 and fixed by glue. The four cylinders 3 are connected by rotation, and the connection method is: two bearings 20 are glued in the cylinder 3, and the bearings 20 are glued on the rotating shaft 21. At this time, the cylinders 3 can rotate freely on the rotating shaft 2, adjacent to each other. There is a vertical plate 18 between the cylinders 3, and the cylinder 3 is provided with a fixed component one for fixing the...

Embodiment 3

[0034] Such as Figure 9 Shown is the third embodiment of the present invention. The difference between this embodiment and Embodiment 1 is that universal brake wheels 16 are installed at the four corners of the bottom surface of the base 1, and the handle 2 17 is welded on the right side of the top surface of the base 1, so that the staff can move the base conveniently. 1. Increase the flexibility of use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com