A kind of halogen-free flame-retardant polyamide composite material and preparation method thereof

A flame retardant polyamide and composite material technology, which is applied to aging-resistant halogen-free flame-retardant polyamide composite materials and their preparation, in the field of high weather resistance, can solve the problems of aging resistance, unsatisfactory weather resistance, limited improvement effect, etc., and achieves good weather resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2、3

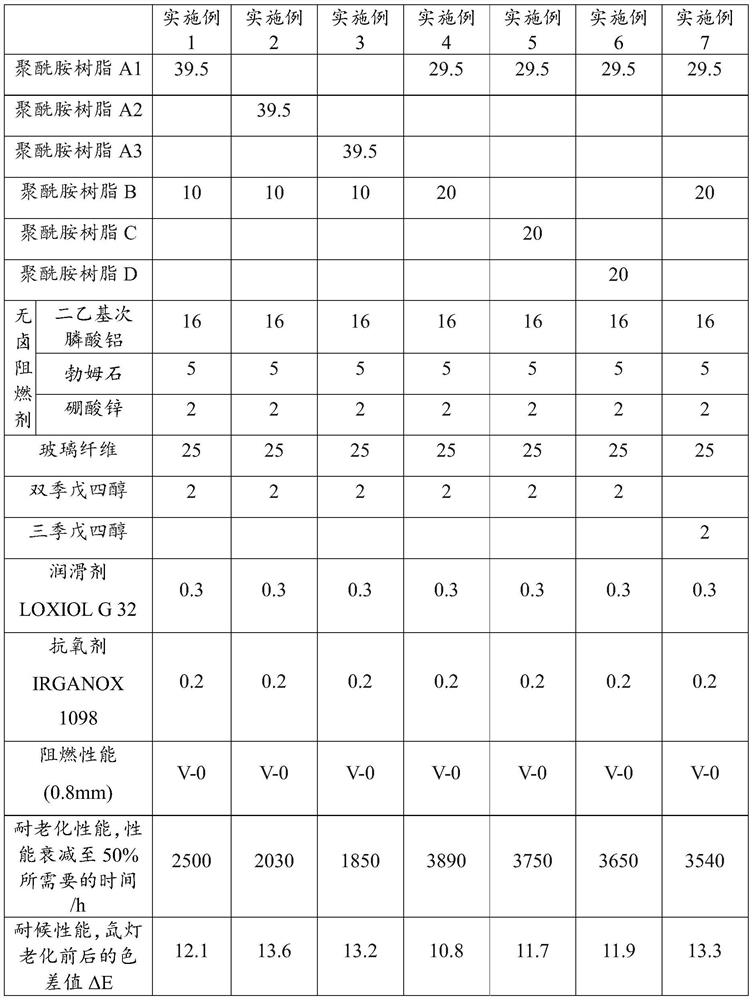

[0052] From the comparison of Examples 1 to 3, it can be seen that the aliphatic polyamide in Example 1 is PA 66, and its aging resistance and weather resistance are better than those of Examples 2 and 3;

[0053]From the comparison of Examples 4 to 6, it can be seen that the aromatic polyamide in Example 4 is PA 6T / 6I, the aromatic polyamide in Example 5 is PA66 / 6T, and the aromatic polyamide in Example 6 is PA. MXD6, aging resistance in embodiment 4,5, weather resistance are better than embodiment 6;

Embodiment 7

[0054] Comparing Example 4 with Example 7, it can be seen that the char-forming agent in Example 4 is dipentaerythritol, the char-forming agent in Example 7 is tripentaerythritol, and the aging resistance and weather resistance in Example 4 are better than those in Example 4. 7;

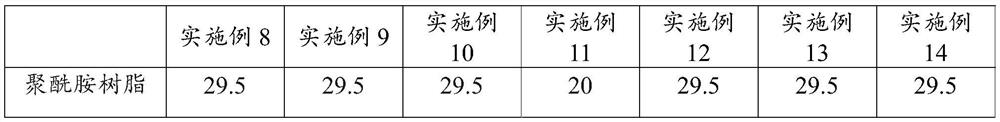

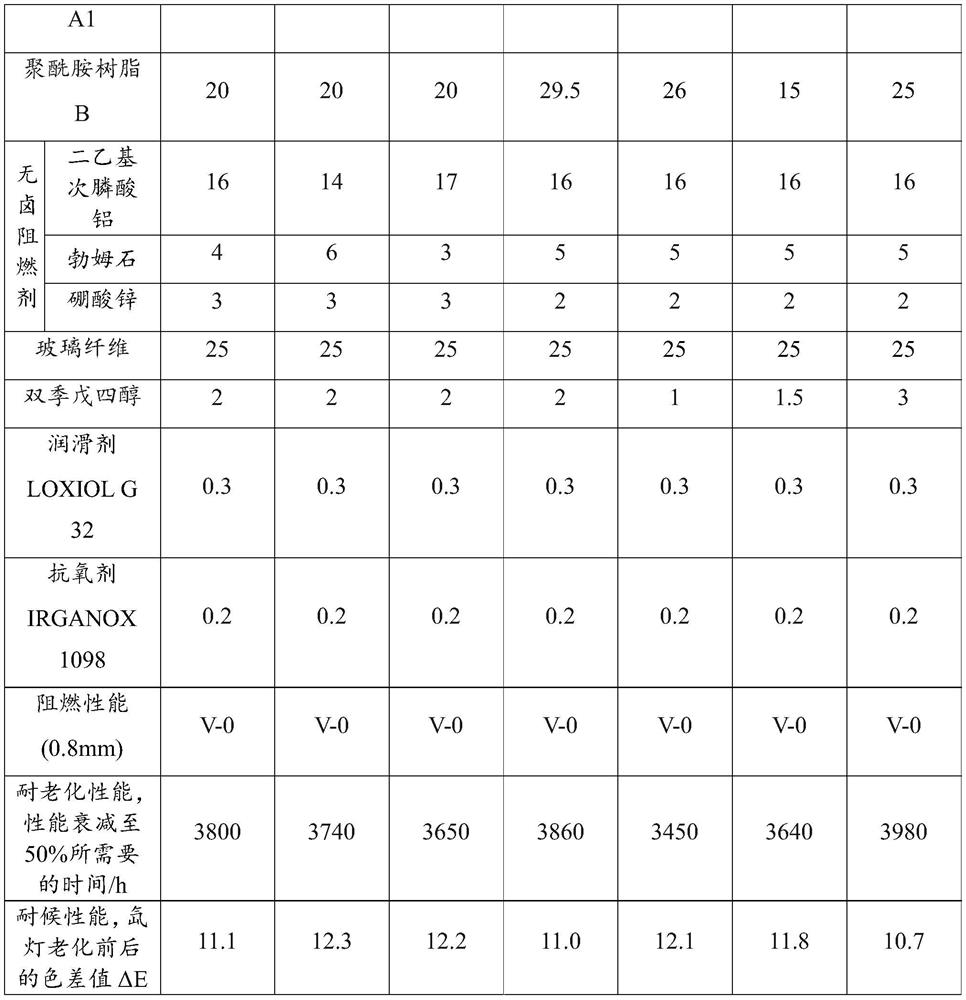

[0055] Comparing Examples 4, 8, 9 to 10 shows that in Examples 4 and 8, the weight ratio of aluminum diethylphosphinate, boehmite and zinc borate is: (15-16): (4-5): (2~3); And in embodiment 9~10, the weight ratio of acid aluminum, boehmite and zinc borate is not in (15~16):(4~5):(2~3) scope, embodiment 4, The aging resistance of 8, weather resistance are better than embodiment 9,10;

Embodiment 12

[0056] Comparing Examples 4, 13, and 14 with Example 12, it can be seen that in Examples 4, 13, and 14, the aromatic polyamide is in the range of 15 to 25 parts, the char-forming agent is in the range of 1.5 to 3 parts, and in Example 12 The aromatic polyamide is not in the range of 15-25 parts, and the char-forming agent is not in the range of 1.5-3 parts. The aging resistance and weather resistance in Examples 4, 13, and 14 are better than those in Example 12;

[0057] From Example 4 and Comparative Examples 1 to 8, it can be seen that the aromatic polyamide and the char-forming agent are not introduced, or one of the aromatic polyamide and the char-forming agent is introduced separately, or both substances are introduced simultaneously, However, the introduction amount or composition is not within the preferred range, and the overall anti-aging, weather resistance and flame retardancy properties of the material are significantly worse than those of Example 4 of the present a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com