Offshore electrical platform pile-sleeve foundation structure with anti-caisson structure

A foundation structure and sleeve technology, applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems that the grouting material cannot be effectively solved under pressure, affects the normal use of offshore electrical platforms, and the bottom of the grouting material is damaged under pressure, etc. , to achieve the effect of improving the leveling construction difficulty, reducing the construction difficulty and shortening the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

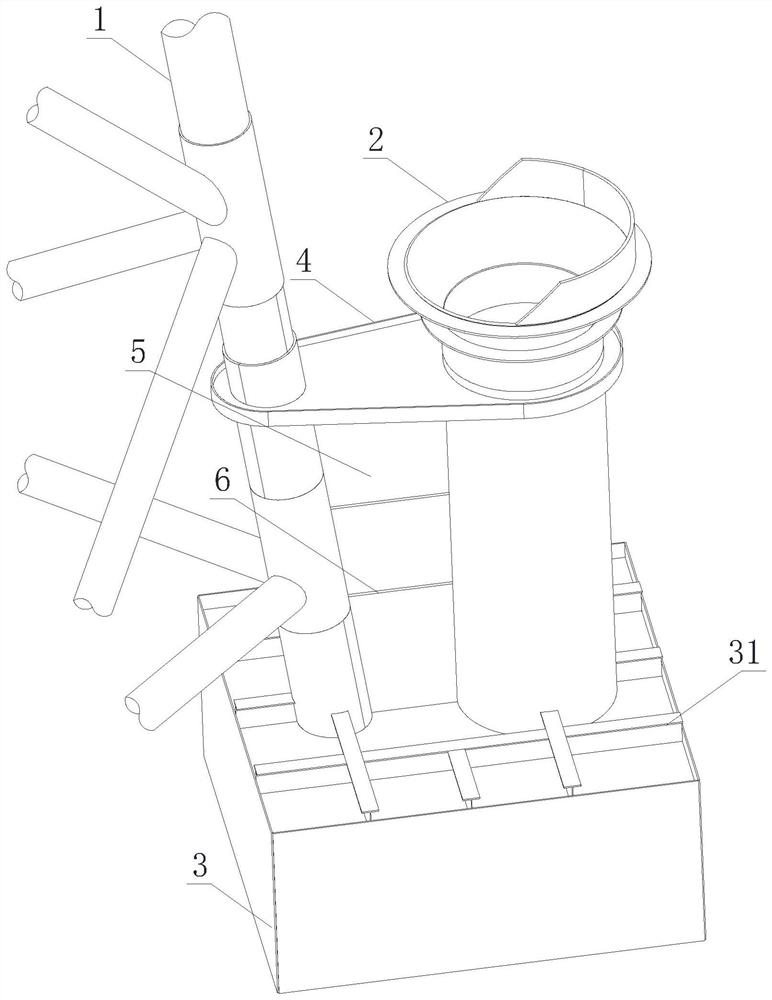

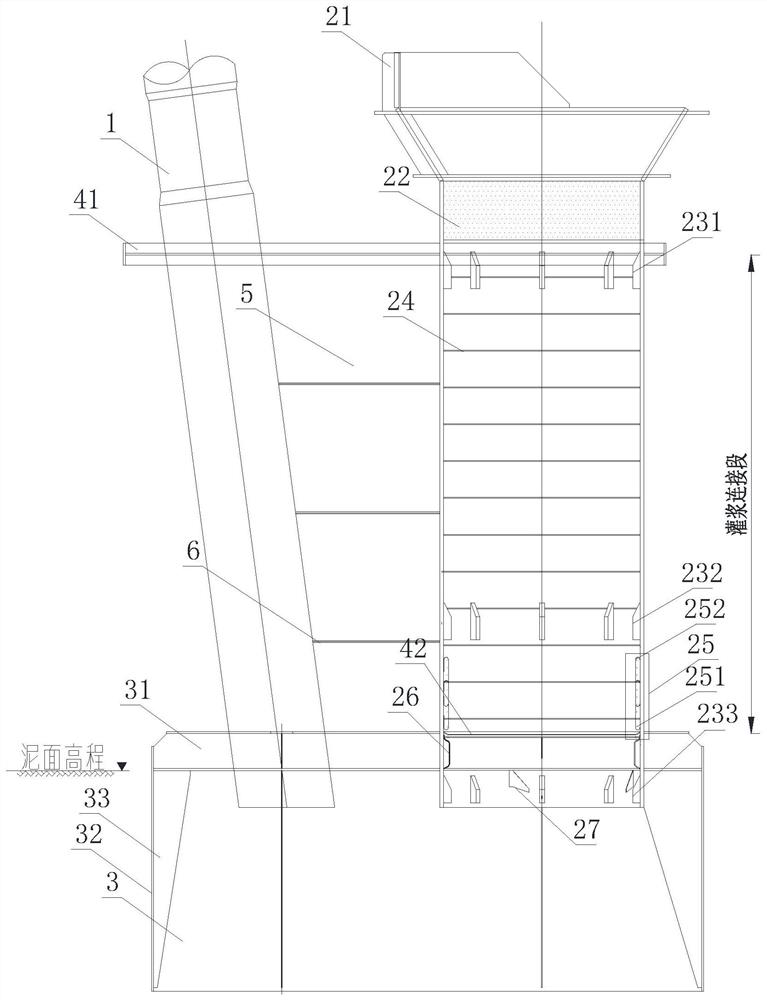

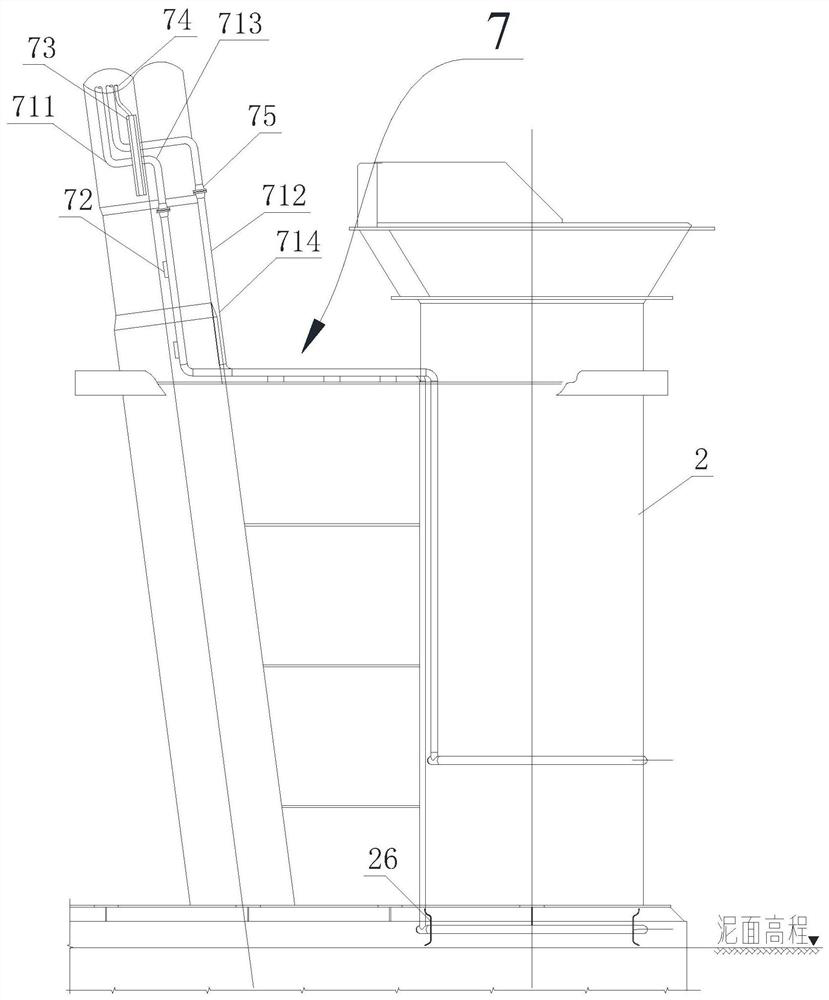

[0038] Such as Figure 1-Figure 8 As shown, a kind of offshore electrical platform pile-sleeve foundation structure with anti-caisson structure provided by the present invention comprises jacket 1 and sleeve 2, anti-caisson 3 is arranged at the bottom of jacket 1 and sleeve 2, jacket 1 A grouting system 7 is arranged between the sleeve 2, a grouting connection section is arranged on the sleeve 2, a reinforcement reinforcement structure 25 is arranged at the bottom of the grouting connection section inside the sleeve 2, and a passive grouting divider 26 is arranged below the reinforcement reinforcement structure 25, The distance between the reinforcement structure 25 and the passive grouting divider 26 is 50mm. Said caisson 3 comprises a top plate 31 on the top floor, a welded panel 34 at the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com