Cemented filling mining method for inclined uphill and downward drift

A technology of cemented filling and mining methods, applied in underground mining, filling, surface mining, etc., can solve the problems of difficult layer transfer, difficult mining of mechanical equipment, high support costs, etc., to increase the length of the stope and improve the efficiency of mining , The effect of high mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

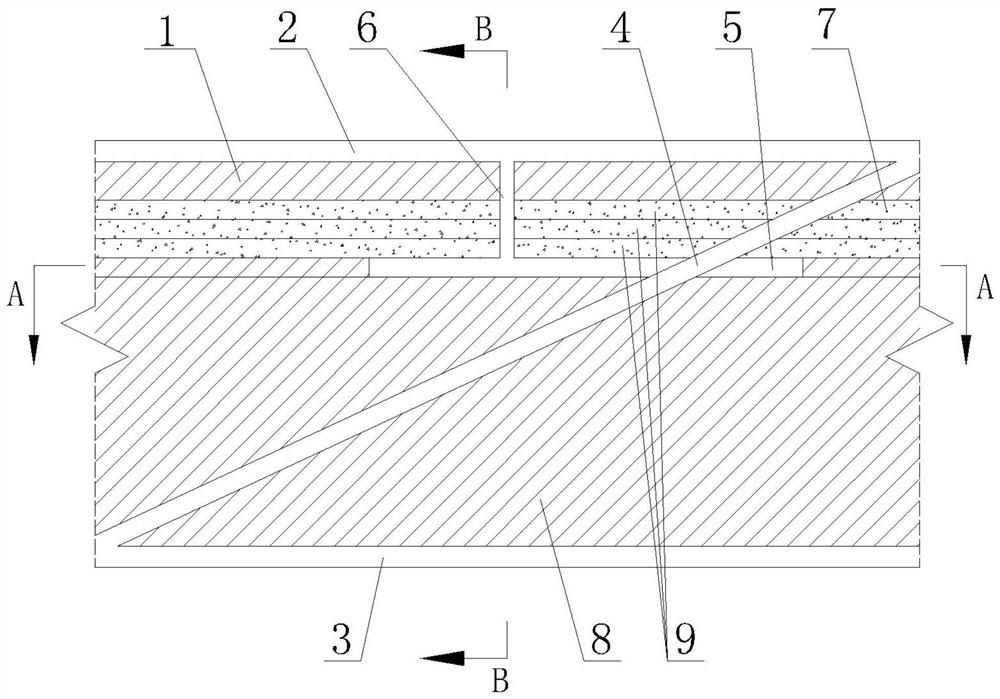

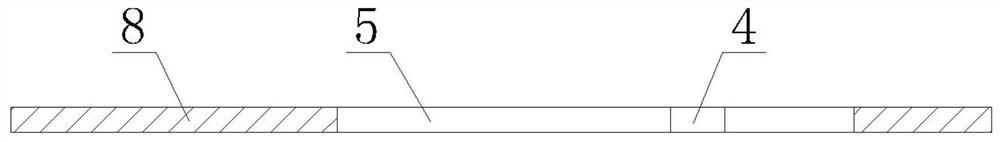

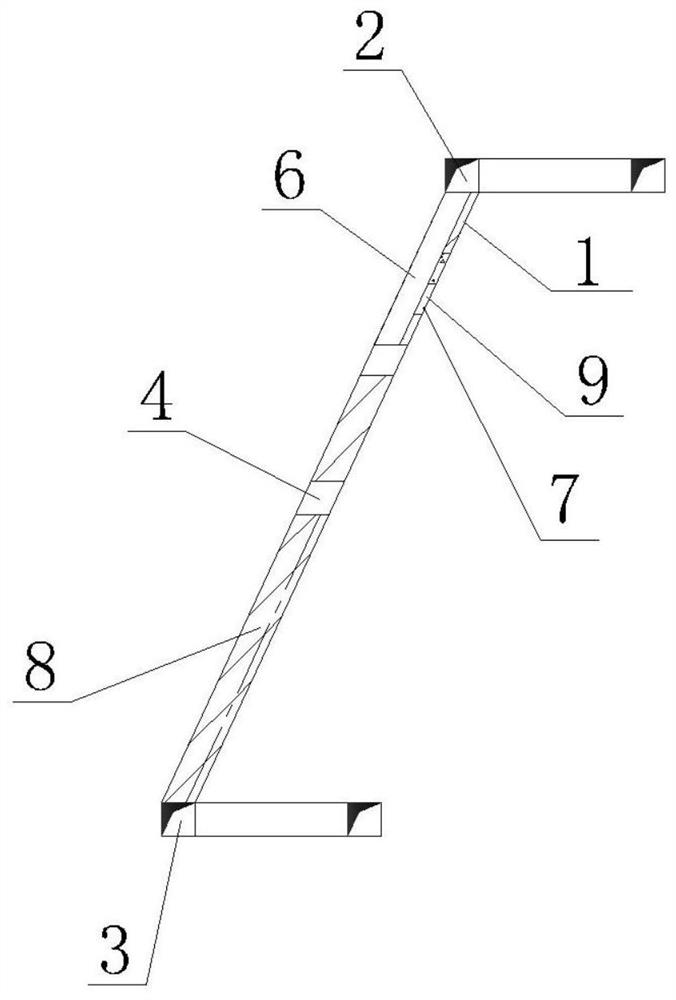

[0060] From Figure 1 to Figure 3 It can be seen that this inclined uphill combined downward approach cemented filling mining method of the present invention comprises the following steps:

[0061] a. Stope design

[0062] The stope is arranged along the 8th direction of the ore body, and the length of the stope is 85-100m; the width of the approach is determined according to the thickness of the ore body, and the width of the approach is generally 2.0-2.5m; the height of the approach is determined by the degree of fragmentation of the ore body, and the height of the approach is generally 2~2.2m;

[0063] b. Accurate cutting project

[0064] b1. Divide the stope into middle sections along the vertical height of the ore vein, the height of the middle section is 40m, and the top pillar 1 with a height of 4-6m is reserved in each middle section, and no bottom pillar is left;

[0065] b2. The upper vein drilling roadway 2 is constructed in the vein at the top of the middle sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com