Preset complete weighing narrow-strip high-speed weighing system

A weighing system and preset technology, applied in the direction of weighing, detailed information of weighing equipment, measuring devices, etc., can solve problems such as affecting measurement accuracy, high construction environment requirements, and high installation level requirements of construction personnel. Achieve the effects of high measurement accuracy, extended effective time and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The structure and features of the present invention will be described in detail below in conjunction with the drawings and embodiments. It should be noted that various modifications can be made to the embodiments disclosed herein, therefore, the embodiments disclosed in the specification should not be regarded as limitations on the present invention, but only as examples of embodiments, and its purpose is to make the present invention The features of the invention are self-evident.

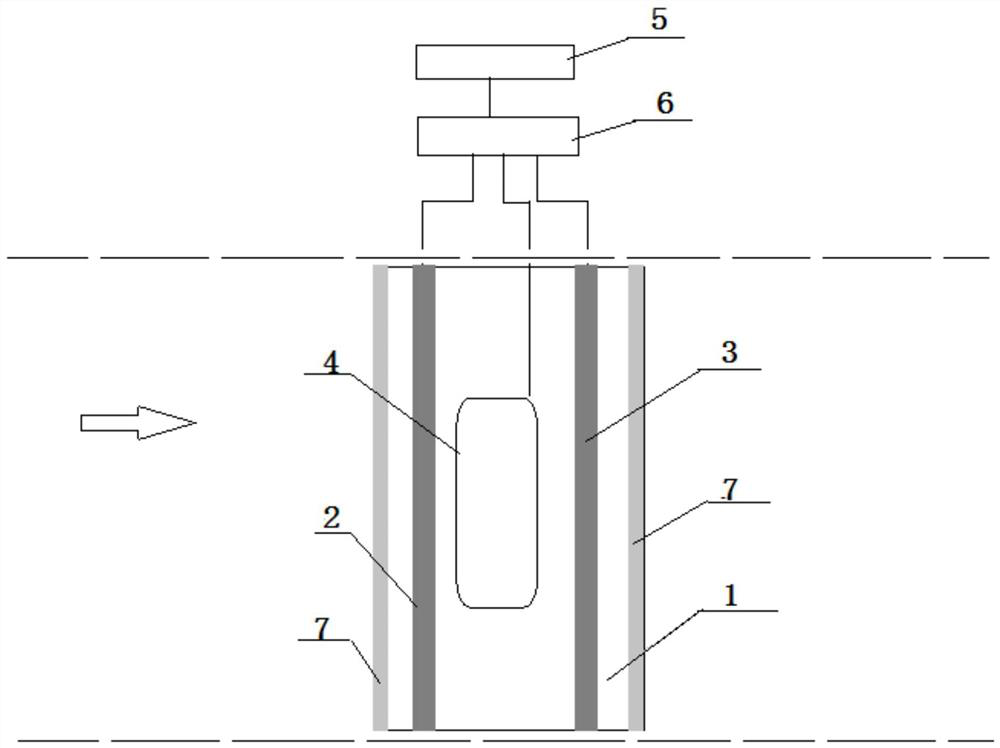

[0025] Such as figure 1 As shown, the preset complete weighing narrow bar high-speed weighing system disclosed in the present invention includes a prefabricated part 1, two narrow bar high-speed weighing tables 2 and 3, a coil type vehicle separator 4, and a data processing unit 5.

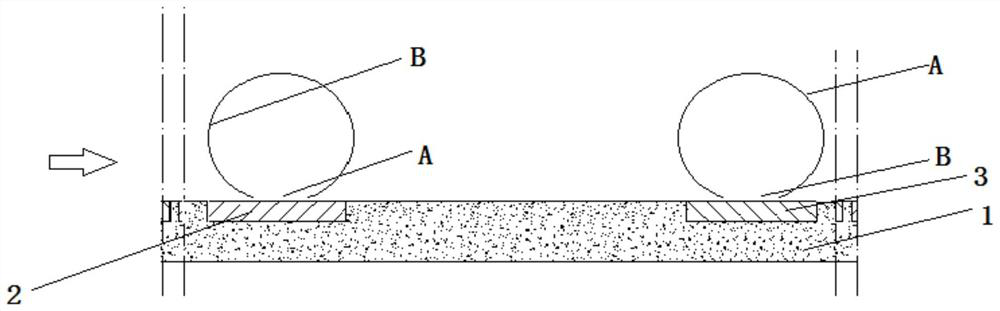

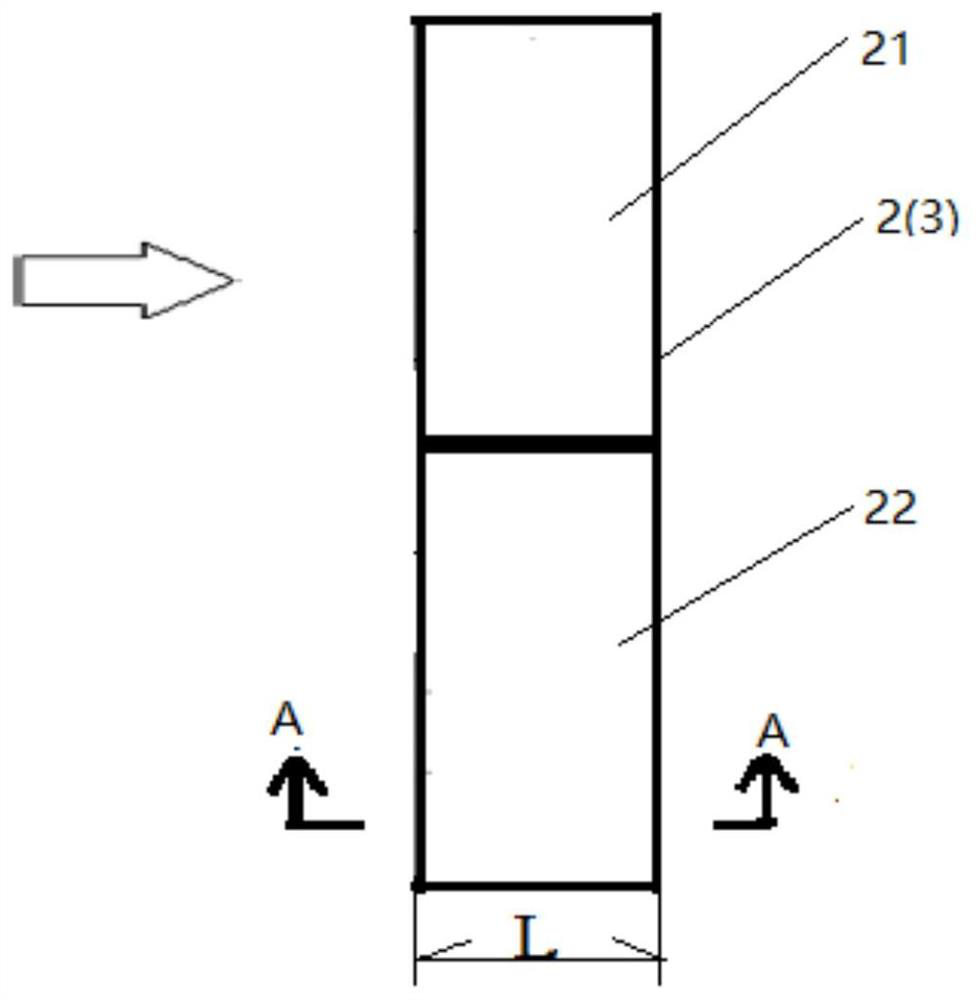

[0026] The prefabricated part 1 is formed by one-time integral pouring of cement mortar and steel bars. Two narrow strip-type high-speed weighing tables 2 and 3 are embedded at intervals in the prefabricated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com