A robust control method for mine filling slurry concentration

A technology of slurry concentration and robust control, applied in adaptive control, general control system, control/regulation system, etc., can solve problems such as modeling difficulties, achieve ease of modeling difficulties, good engineering significance, and external interference suppression Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

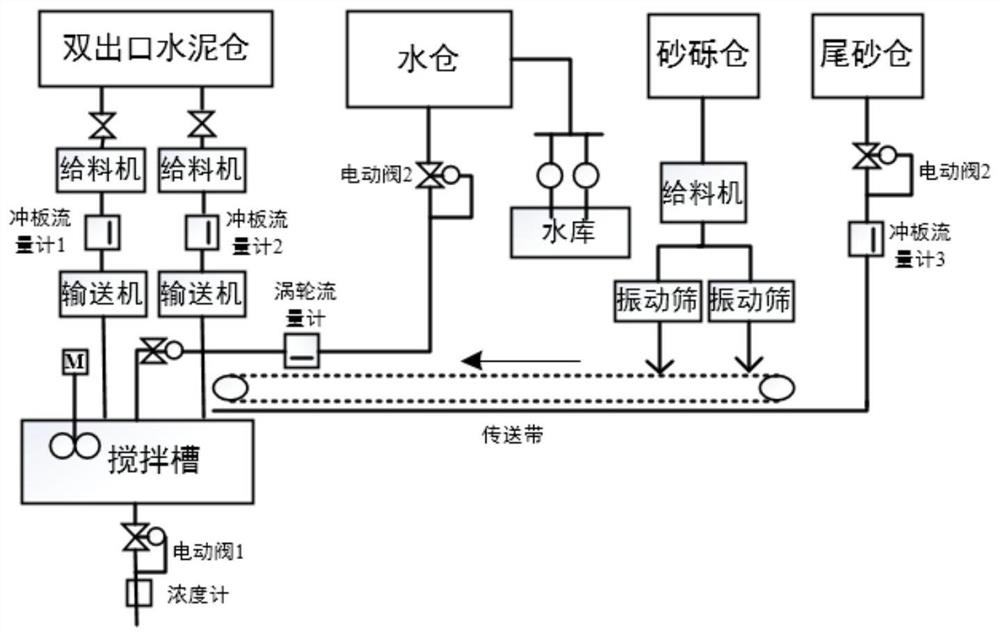

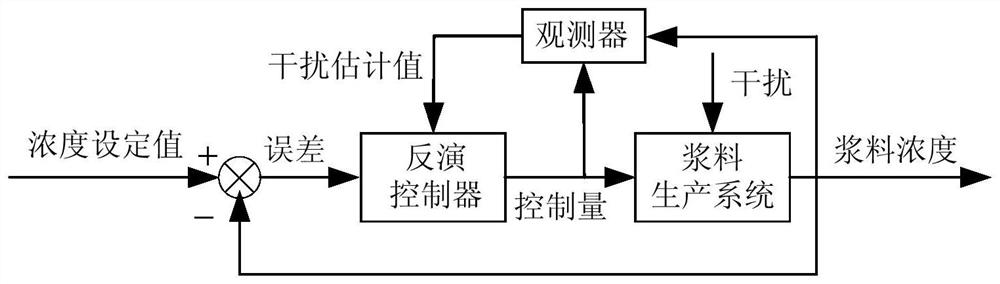

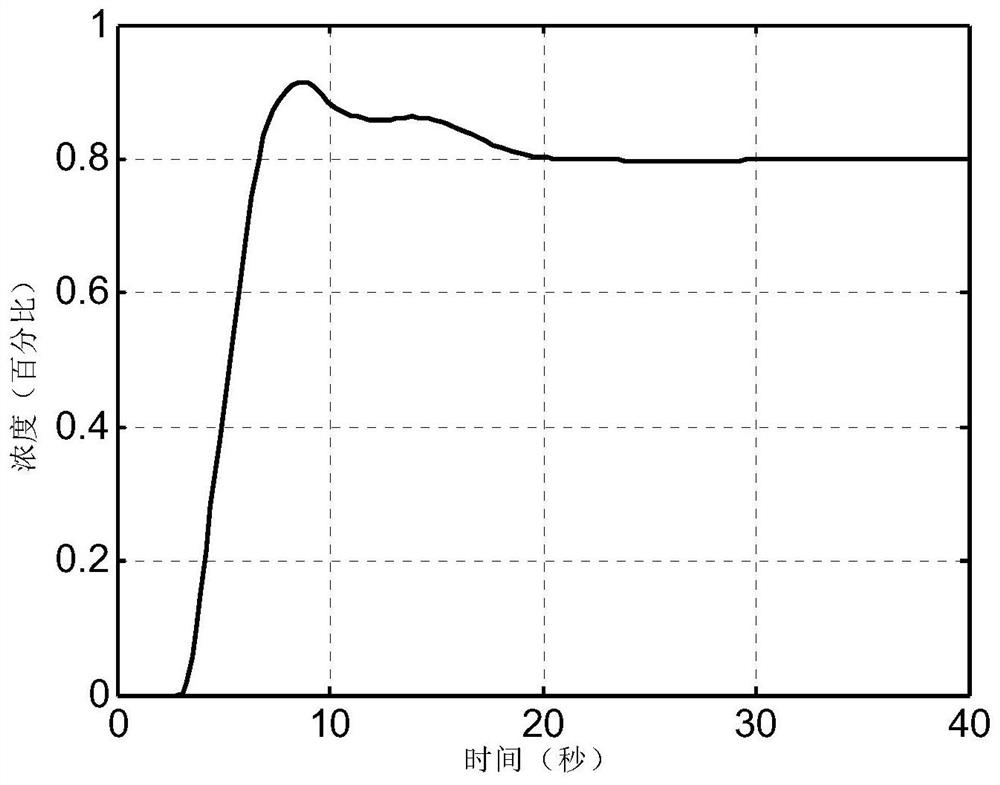

[0027] Aiming at the problems existing in the current concentration control of mine filling slurry production, the present invention proposes a robust control method based on observer and inversion control. The main idea is to establish the slurry production system model, regard the disturbance as an additional state of the system and estimate it through the observer, and finally design the controller through the inversion control method. The control principle is as follows: figure 2 shown. Depend on figure 2 It can be seen that the output of the controller and the slurry production system is used as the input of the observer, and the estimated value of the disturbance of the system is obtained, which is then used for the design of the inverse controller.

[0028] First, the mathematical model of the slurry production system in the prior art is introduced.

[0029] It can be seen from the process that the slurry production process is a multi-input single-output system. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com