Impact type camellia oleifera fruit picker

A technology of camellia oleifera fruit and picker, which is applied in picking machines, agricultural machinery and implements, agriculture, etc., can solve the problems of shortening picking time and long pull-down stroke, and achieve the effects of shortening picking time, long pull-down stroke and lightening load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: figure 1 is a schematic structural view of embodiment 1, which consists of a fork 1 and a conduit 2, such as figure 1 As shown, the fork 1 is composed of a fork 1-1, a cylinder 1-2, and a conduit interface 1-3. The upper entrance of the cylinder 1-2 is rectangular, about 14 centimeters long and about 7 inches wide. cm, a row of main fork teeth 1-1 are respectively arranged on the top of the left and right side walls of the cylinder body 1-2, the main fork teeth 1-1 are conical, the diameter of the upper end is about 10 mm, and the diameter of the lower end is about 12 mm. About 6-9 centimeters, the upper end gap between the adjacent main fork teeth 1-1 is about 22 mm, and the lower end gap is about 20 mm; each of the main fork teeth 1-1 is inclined from bottom to top to the outside , the angle between the main fork teeth 1-1 in the left row and the main fork teeth 1-1 in the right row is about 45-75 degrees; Auxiliary fork 1-1, the auxiliary fork 1-1 is cy...

Embodiment 2

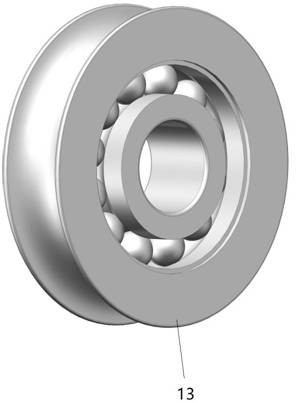

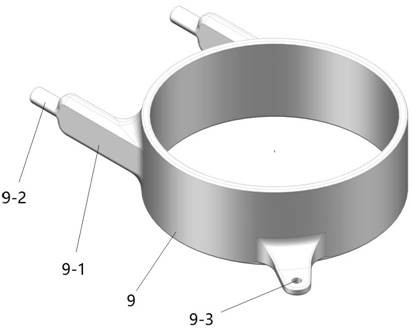

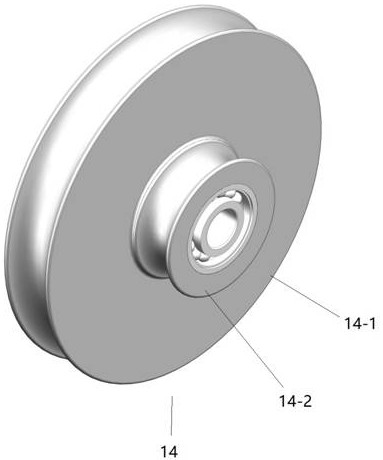

[0036] Embodiment 2: as Figure 2 to Figure 17 As shown, as a further improvement to Embodiment 1, it is also provided with a hand-held rod 3, and the conduit 2 is hinged to the upper end of the hand-held rod 3 in a sliding manner up and down: Fastening ring 7 and second fastening ring 8; described first fastening ring 7 is provided with upper circular ring 7-1, and described second fastening ring 8 is provided with lower circular ring 8-1, in described The upper ring 7-1 and the top of the lower ring 8-1 are respectively provided with a group of slide rails 11 consisting of several small pulleys 12, and the inscribed circles of each of the small pulleys 12 in the slide rails 11 The diameter is adapted to the outer diameter of the conduit 2; the lower end of the conduit 2 extends into the upper and lower sets of slide rails 11, and can go up and down along the trajectory determined by the upper and lower sets of slide rails 11 slide.

[0037] The driving mechanism 4 used to ...

Embodiment 3

[0044]Embodiment 3: Different from Embodiment 1, in Embodiment 3, the upper end inlet of the cylinder body 1-2 is circular, with an inner diameter of about 8-12 cm, and the fork tine 1-1 is cylindrical, The top is rounded, about 6 cm long, and about 1 cm in diameter. Each of the fork tines 1-1 is evenly arranged on the top of the cylinder 1-2 in a circular array, and each of the fork tines 1-1 is from bottom to top , Slightly inclined to the outside, the lower end gap between the adjacent fork tines 1-1 is about 19 mm, and the upper end gap is about 22 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com