Composite waste gas treatment machine

A waste gas treatment and composite technology, applied in the direction of cleaning hollow objects, dispersed particle filtration, cleaning methods and appliances, etc., can solve the problems of accelerated aging of filter parts, smaller diameter of air inlet, retention, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029]Such asFigure 1-Figure 6 As shown, the present invention provides a technical solution for a composite exhaust gas treatment machine:

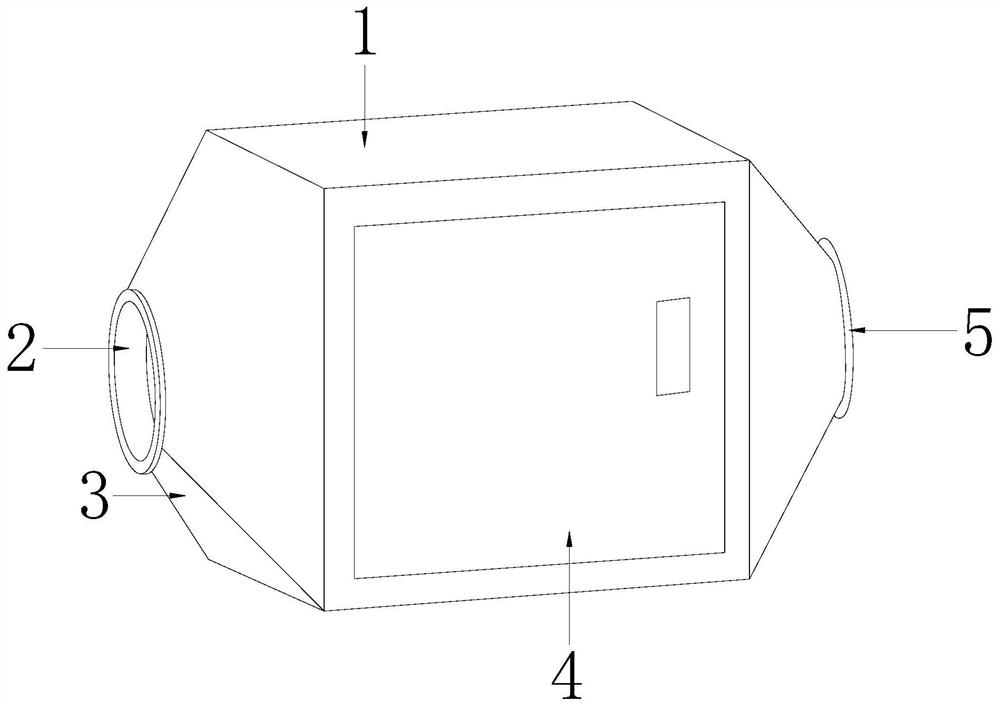

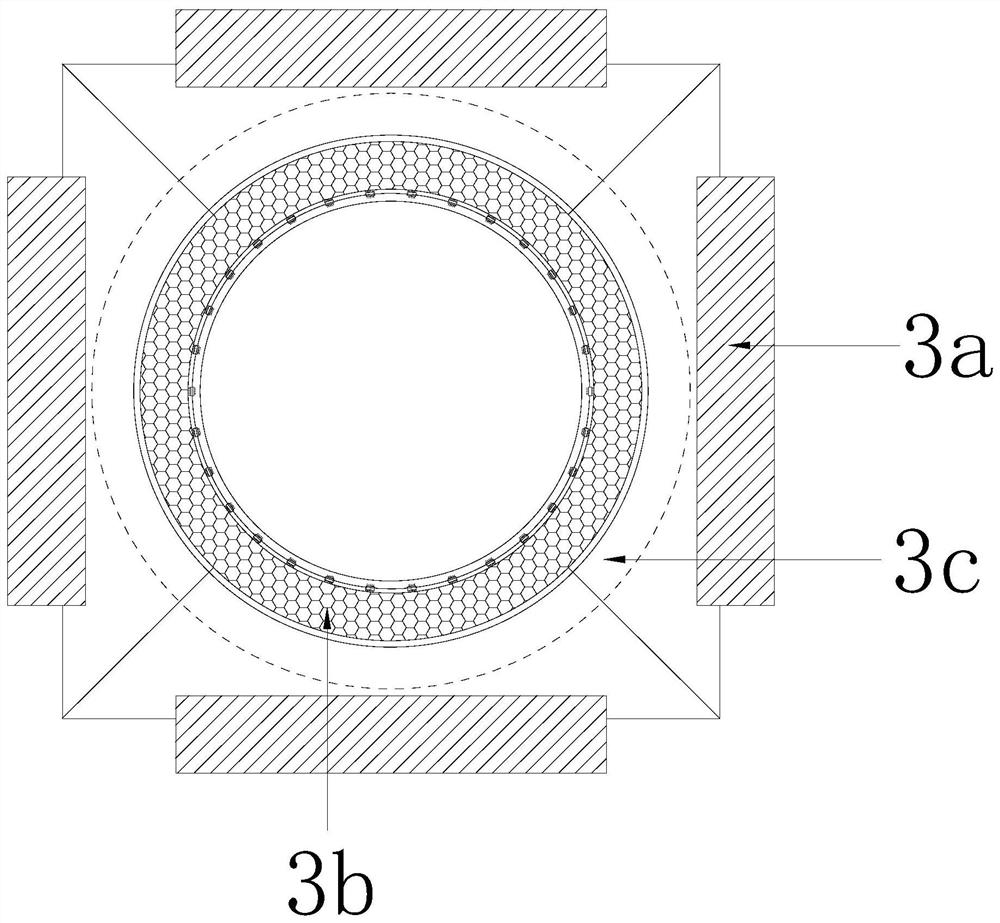

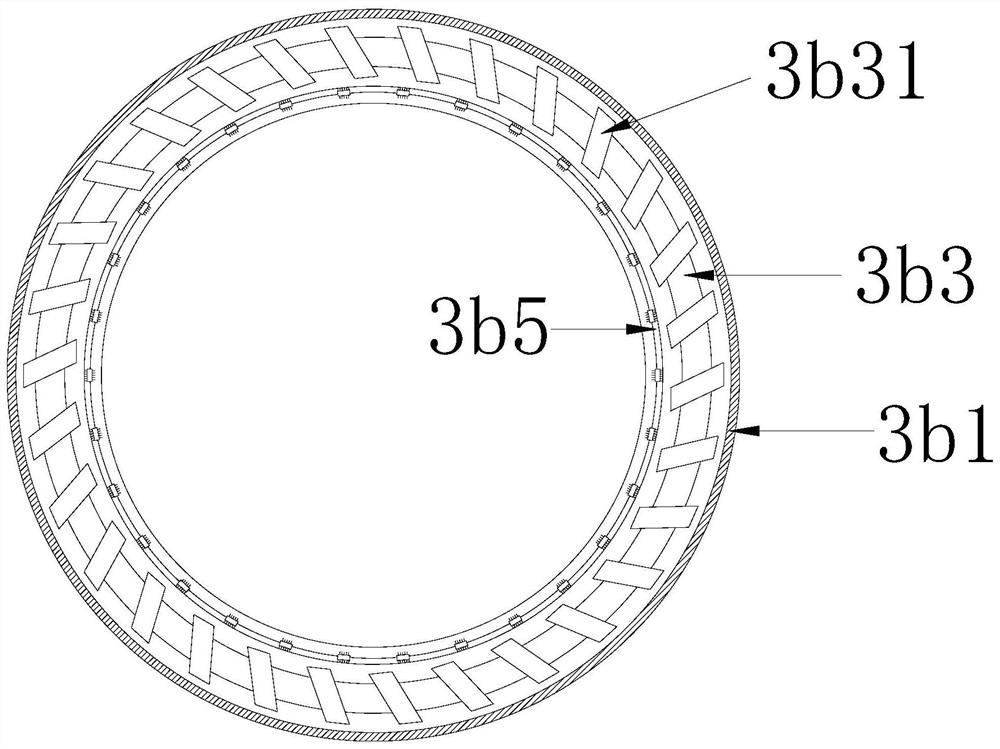

[0030]Such asFigure 1-Figure 2 As shown, a composite exhaust gas treatment machine has a structure including a body 1, an air inlet 2, a restraining device 3, an inspection door 4, and an air outlet 5. The air inlet 2 is provided on the left side of the body 1 and is an integrated structure The suppression device 3 is installed on the left side of the body 1 and corresponds to the air inlet 2, the inspection door 4 is provided on the front surface of the body 1, and the air outlet 5 is installed on the right side of the body 1 and is an integrated structure The attachment suppression device 3 includes a buckle plate 3a, an anti-scaling pile mechanism 3b, and an anti-scaling structure 3c. The anti-scaling pile mechanism 3b is arranged in the middle of the buckle plate 3a, and the anti-scaling structure 3c is arranged in an anti-scaling pile. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com