Activated carbon activation and regeneration device with adaptive function and activation and regeneration method thereof

A regeneration device, activated carbon technology, applied in separation methods, filter regeneration, combustible gas purification, etc., can solve the problems of complete damage to the structure, arc pulse discharge of electrode plates, waste, etc., to improve activation regeneration efficiency, reduce tension Arc pulse discharge phenomenon, the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

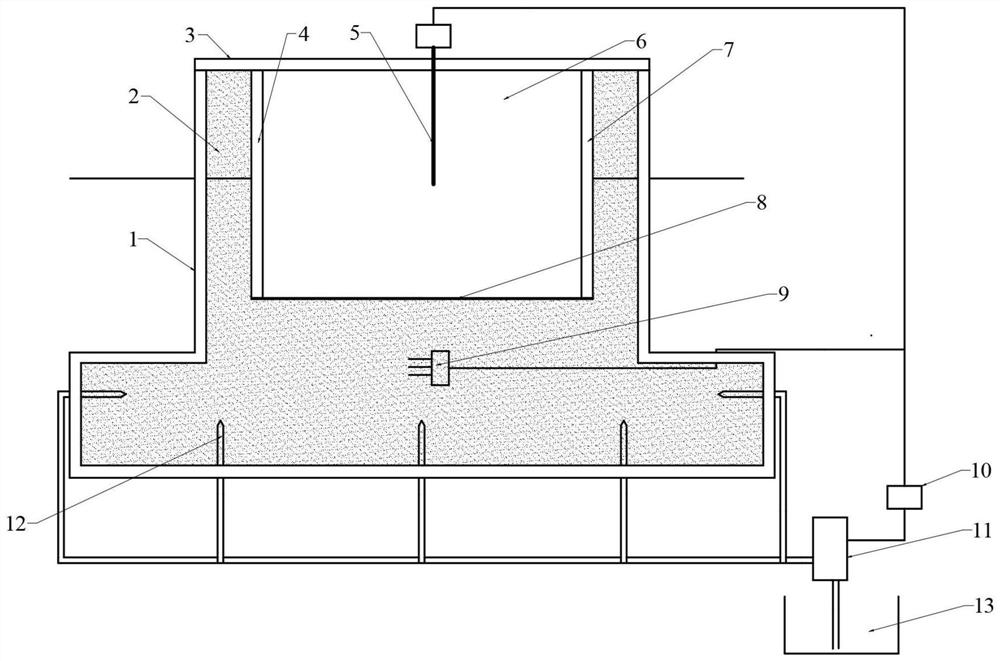

[0030] like figure 1 As shown in the figure, an activated carbon activation and regeneration device with adaptive function includes a casing 1, sand grains 2, an upper cover plate 3, a first electrode plate 4, a second electrode plate 7, a temperature sensor 5, an insulating pad 8, a humidity Sensor 9 , PLC control system 10 , peristaltic pump 11 , water spray nozzle 12 and water tank 13 . The housing 1 is hollow and has an open top. The shell 1 is filled with sand grains 2 . Sand 2 uses quartz sand (ie, silica particles) extracted in an outdoor environment. The first electrode plate 4 , the second electrode plate 7 and the insulating cloth 8 are all arranged on the top of the inner cavity of the casing 1 . The vertical first electrode plate 4 and the second electrode plate 7 are disposed opposite to each other, and form a horizontal sliding sliding pair with the casing, so as to adjust the distance between the first electrode plate 4 and the second electrode plate 7 . The...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is:

[0046] In step 1, the width of the regenerated honeycomb activated carbon is 5 cm, and the distance between the first electrode plate 4 and the second electrode plate 7 is adjusted to 5 cm.

[0047] In step 2, the humidity in the gap between sand grains 2 is 30%;

Embodiment 3

[0049] The difference between this embodiment and Embodiment 1 is:

[0050] The regenerated activated carbon is activated carbon powder or unshaped granules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com