Punch forming device for metal cover of food packaging tin

A technology for stamping and forming and food packaging, applied in the field of stamping devices, can solve the problems that the to-be-stamped parts are easily adhered to the upper and lower stamping dies, the to-be-stamped parts are prone to shaking, and consumes a lot of human resources, so as to avoid shaking. , The structure design is reasonable, the effect of saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

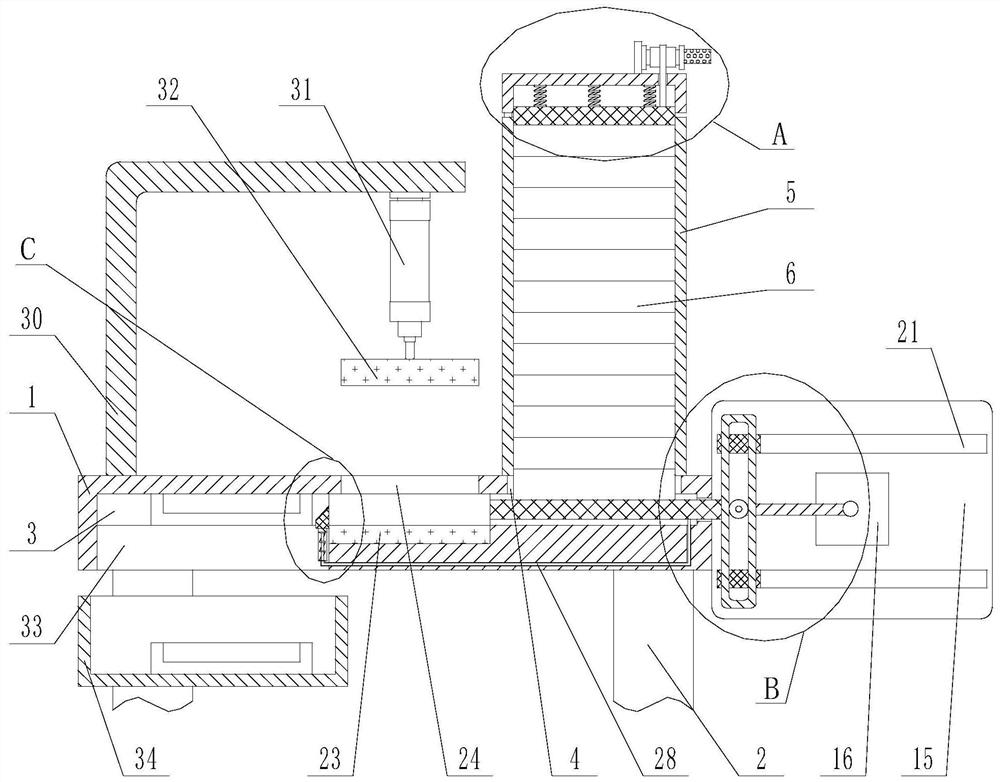

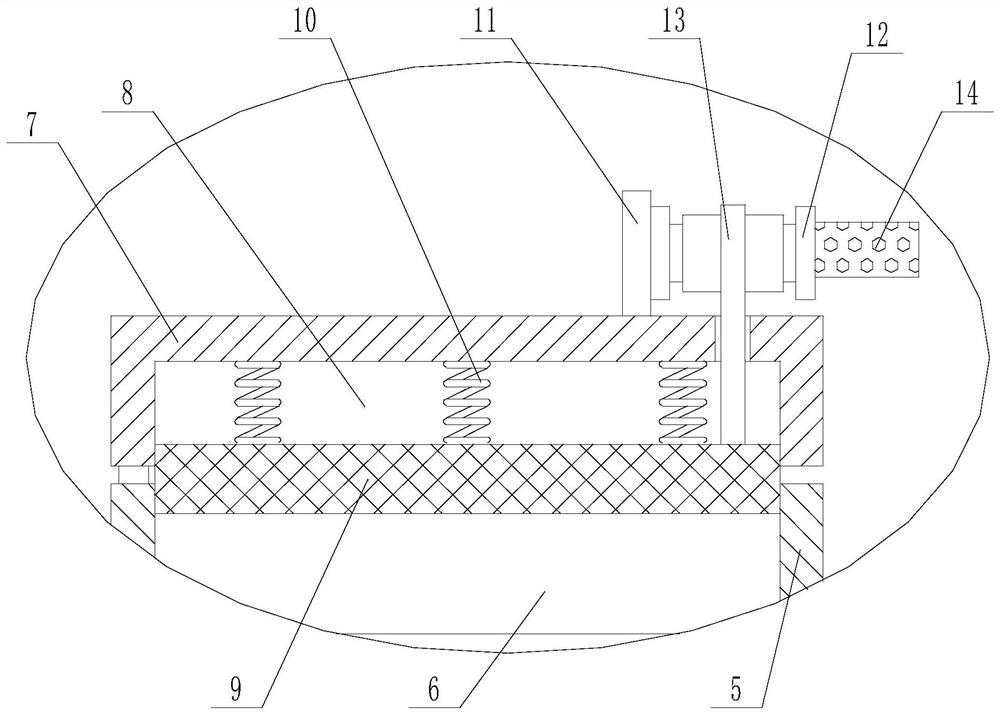

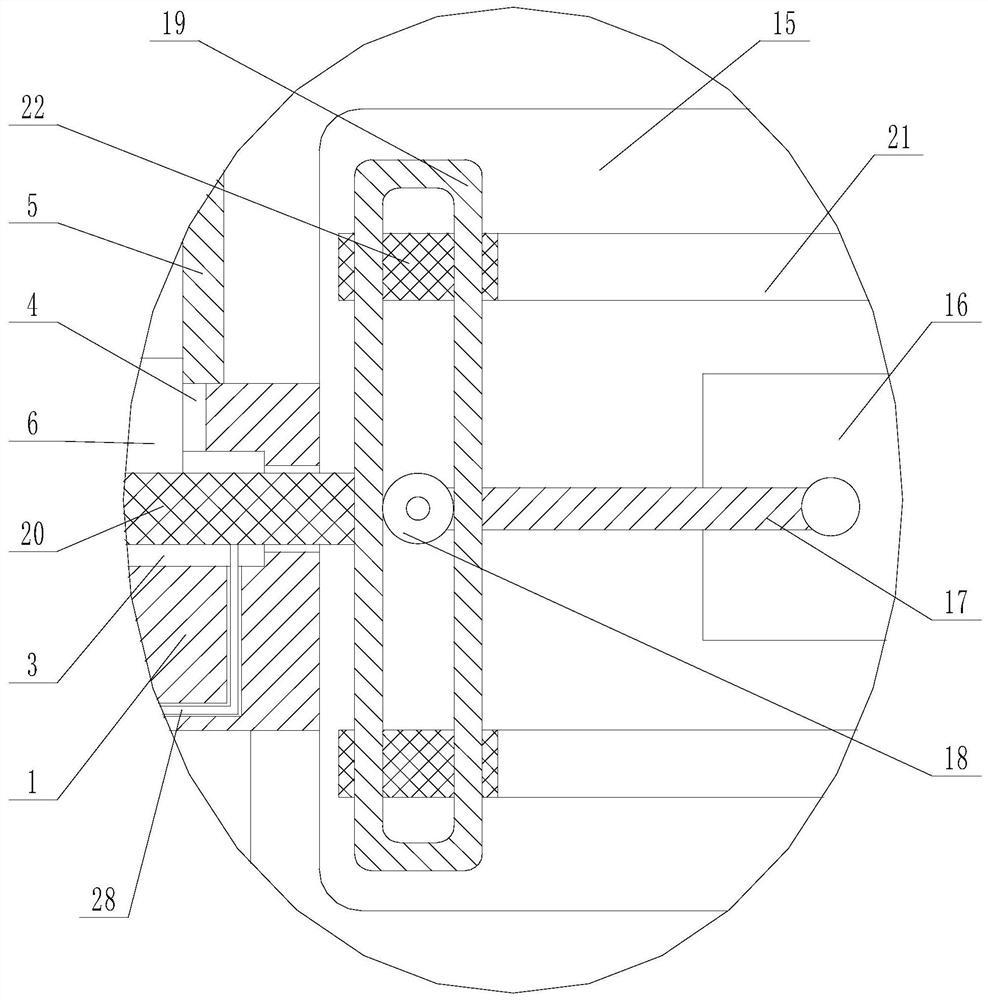

[0025]Such asFigure 1-5As shown, a stamping and forming device for a metal lid of a food packaging can includes a worktable 1 and a part to be stamped 6. The bottom of the worktable 1 is fixedly connected with four support legs 2, and the worktable 1 is provided with a guide groove 3 for working The upper end of the table 1 is provided with a communicating groove 4, and the upper end of the working table 1 is fixedly connected with a storage mechanism opposite to the communicating groove 4, and the stamping part 6 is placed in the storage mechanism. The storage mechanism includes a fixed connection to the upper end of the working table 1. And the storage box 5 opposite to the communicating groove 4, the to-be-punched part 6 is placed in the storage box 5. It should be noted that the to-be-punched part 6 at the bottom passes through the communicating groove 4 and extends into the guide groove 3 , The upper end of the storage box 5 is rotatably connected with a cover 7, and the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com