Clamping device for laser cutting machine

A laser cutting machine and clamping device technology, applied in auxiliary devices, laser welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of base plate damage, lack of adjustment, troublesome fixing, etc., and achieve simple design and structure of the device. Easy cutting operation, easy fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

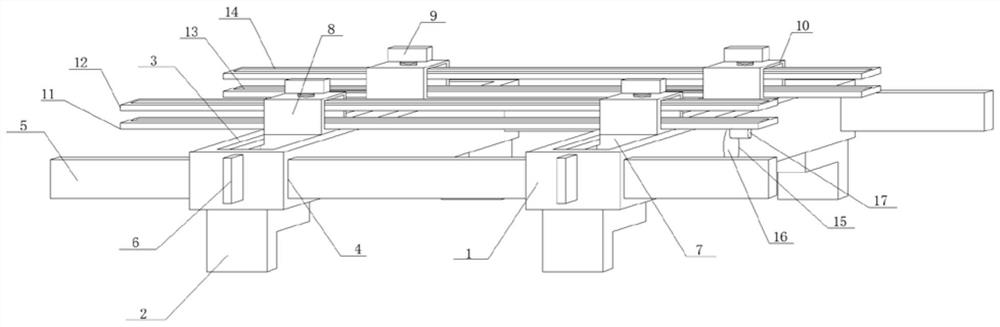

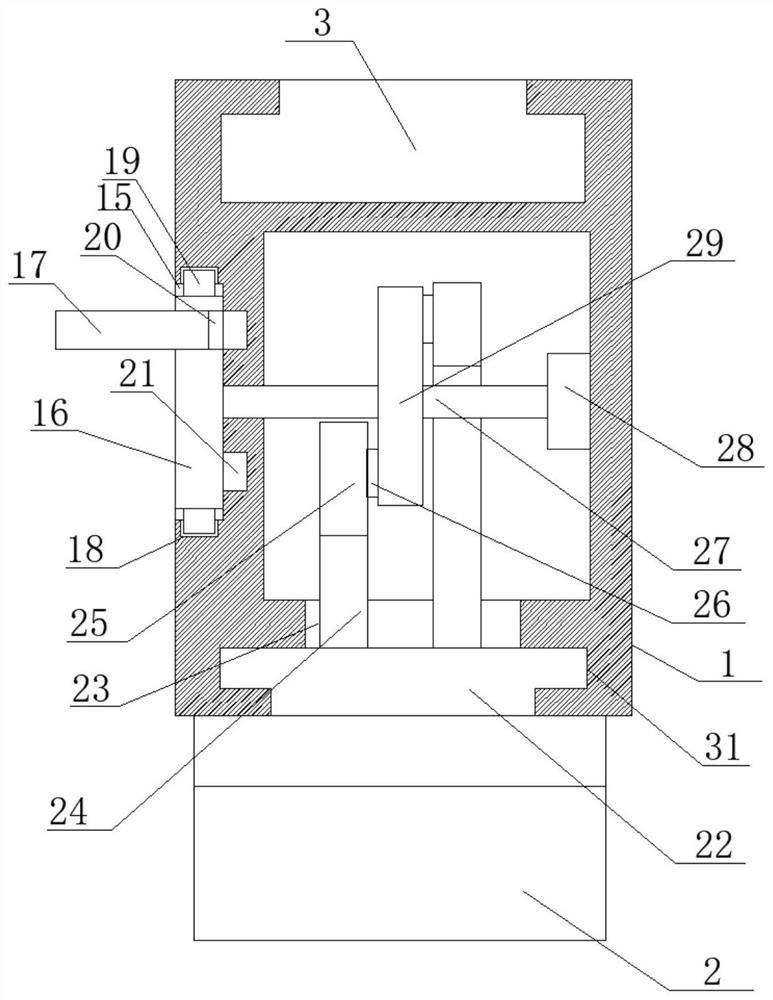

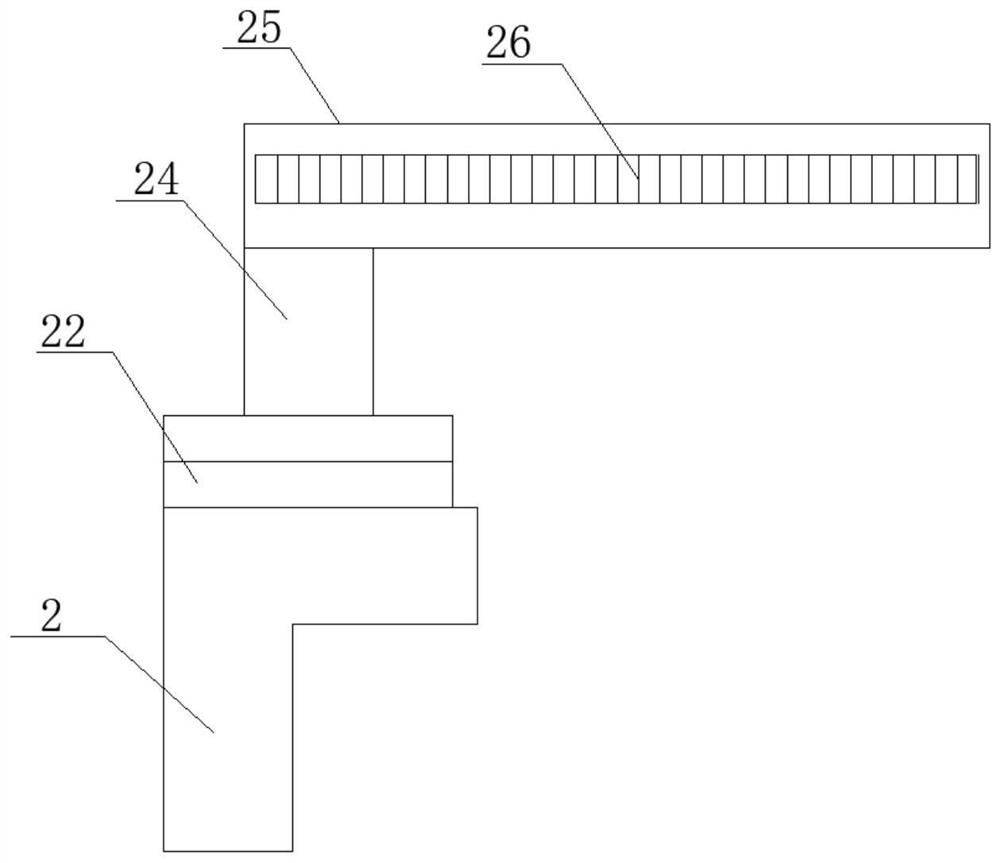

[0026] see Figure 1-3 , in an embodiment of the present invention, a clamping device for a laser cutting machine includes a fixed cross bar 1, the bottom surface of the fixed cross bar 1 is connected with an extrusion block 2, and the top surface of the fixed cross bar 1 is horizontally provided with a movable chute 3. The number of fixed crossbars 1 is two, and the two fixed crossbars 1 are arranged parallel to each other, the number of extrusion blocks 2 is four, and the four extrusion blocks 2 are symmetrical in pairs It is arranged on the bottom surface of the fixed cross bar 1 close to both ends, the extruding block 2 is arranged in an L-shaped structure, the movable chute 3 is horizontally opened on the central axis of the top surface of the fixed cross bar 1, and the side of the fixed cross bar 1 is symmetrically opened horizontally There are insertion holes 4, the inner sides of the insertion holes 4 are horizontally inserted into the limit strips 5, the insertion hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com